Method for transferring workpieces to enter and exit vacuum environment and ensuring workpieces to pass through processing region in vacuum environment and equipment

A technology of processing area and workpiece, applied in the field of vacuum transmission process, can solve the problems of low production efficiency and workpiece cannot be processed continuously, and achieve the effect of improving efficiency, saving time and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

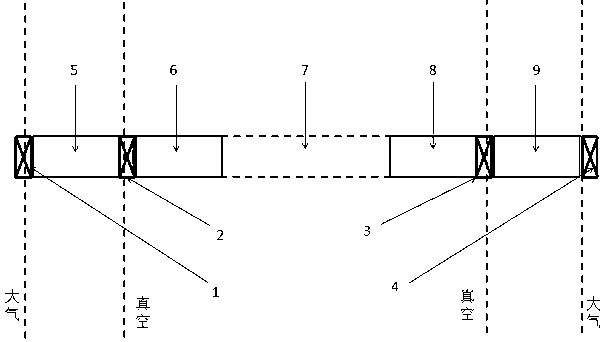

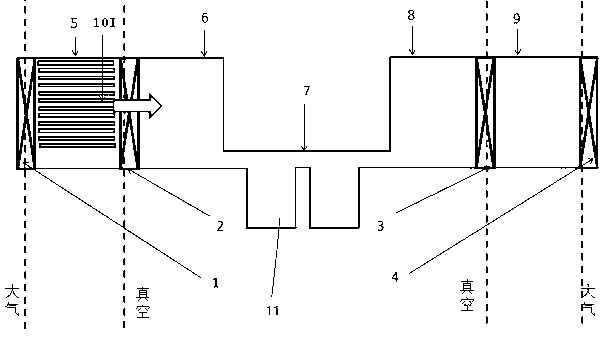

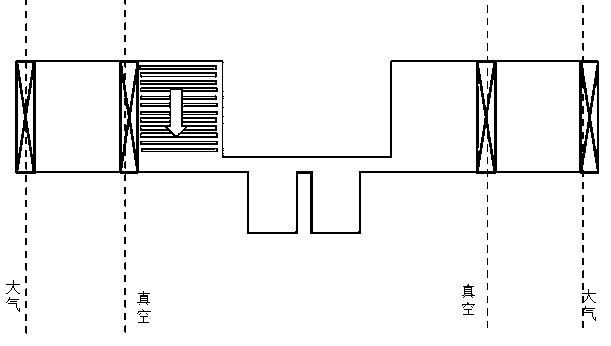

[0051] to combine Figure 1 to Figure 8 , the method and equipment for transferring workpieces in and out of the vacuum and passing through the processing area in the vacuum according to the present invention are described in detail.

[0052] Such as figure 1 As shown, the device for transferring workpieces in and out of the vacuum and passing through the processing area in vacuum according to the present invention, the front buffer zone 6, the processing zone 7 and the rear buffer zone 8 in the middle together form a vacuum process chamber, the front buffer zone 6, the processing zone The 7 and the rear buffer zone 8 communicate with each other.

[0053] The film feeding chamber 5, the vacuum process chamber, and the film discharging chamber 9 are connected through the valve B2 and the valve C3 in sequence. Another valve A1 and a valve D4 are provided in the film feeding chamber 5 and the film discharging chamber 9 respectively. Through the control of valve A1 and valve D4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com