SF6 local discharge decomposing device with micro-water injector and experiment method

A partial discharge and micro-moisture technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., to improve the accuracy of detection, ensure the reliability of experiments, and facilitate the promotion of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

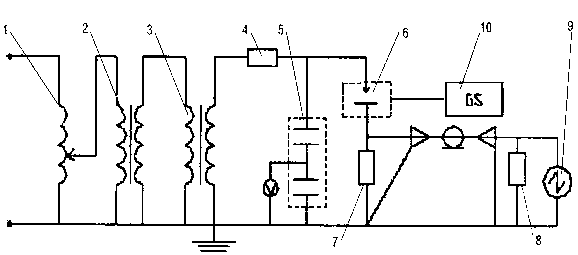

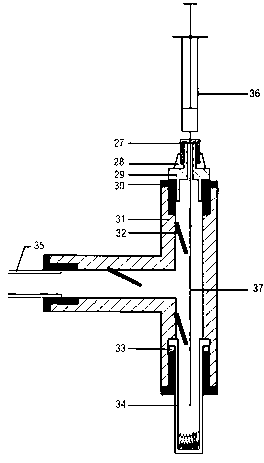

[0037] Such as figure 2 , 3 Shown, a SF with trace moisture injector 6 Partial discharge decomposition device, mainly including voltage regulator console 1, isolation transformer 2, non-corona test transformer 3, non-PD protection resistor 4, capacitor voltage divider 5, SF 6 Partial discharge decomposition device 6, non-inductive detection impedance 7, matching impedance 8, oscilloscope 9, gas chromatograph 10, trace moisture injector 26, etc. It is characterized in that the trace water injector 26 is mainly composed of a trace water sampling needle 36 , a stainless steel thin tube 37 , a three-way valve 31 , a quartz glass test tube 34 and a sampling head 29 . The trace moisture injector 26 is connected to the SF via a trace moisture injector ball valve 25 6 SF of Partial Discharge Decomposition Device 6 6 The gas discharge breaks down the components on the main gas line at the inlet portion of the sampling valve 22 .

[0038] The micro-water injection needle is a comm...

Embodiment 2

[0043] A SF with trace moisture injector 6The partial discharge decomposition device is the same as in Example 1. Wherein said micro-water sampling needle 36 is a syringe with a scaled capacity of 200 μl; the stainless steel thin tube 37 on the needle of said micro-water sampling needle 36 has a length of 115 mm, an inner diameter of 0.6 mm, and a wall thickness of 0.4 mm. mm; the length of the pipe at the upper and lower ends of the three-way valve is 100mm, the length of the side end pipe is 65mm, the internal diameter of the three-end pipe is 12mm, and the wall thickness is 8mm; the upper end cylinder of the described sampling head 29 The length of the shaped tube is 12mm, the internal diameter is 2mm, and the wall thickness is 1.5mm. The length of the cylindrical tube in the middle section of the sampling head 29 is 6mm, the internal diameter is 2mm, and the wall thickness is 6mm. The cylindrical tube at the lower end of the sampling head 29 The length of the test tube is...

Embodiment 3

[0045] A SF with trace moisture injector 6 The partial discharge decomposition device is the same as in Example 1. Wherein said micro-water sampling needle 36 is a syringe with a scaled capacity of 250 μl; the stainless steel thin tube 37 on the needle of said micro-water sampling needle 36 has a length of 120 mm, an inner diameter of 0.7 mm, and a wall thickness of 0.3 mm. mm; the length of the pipe at the upper and lower ends of the three-way valve is 90mm, the length of the side end pipe is 60mm, and the inner diameter of the three-way pipe is 15mm, and the wall thickness is 6mm; the upper end cylinder of the described sampling head 29 The length of the shaped tube is 14mm, the internal diameter is 4mm, and the wall thickness is 1mm. The length of the cylindrical tube in the middle section of the sampling head 29 is 7mm, the internal diameter is 4mm, and the wall thickness is 5mm. The cylindrical tube at the lower end of the sampling head 29 The length is 14mm, the inner d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com