Vibration sensor of three-component fiber grating

A vibration sensor, fiber grating technology, applied in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of easy distortion of spectral signals, low measurement frequency of fiber grating sensors, etc., to widen the measurement frequency range and improve stability. The effect of preventing over-range damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

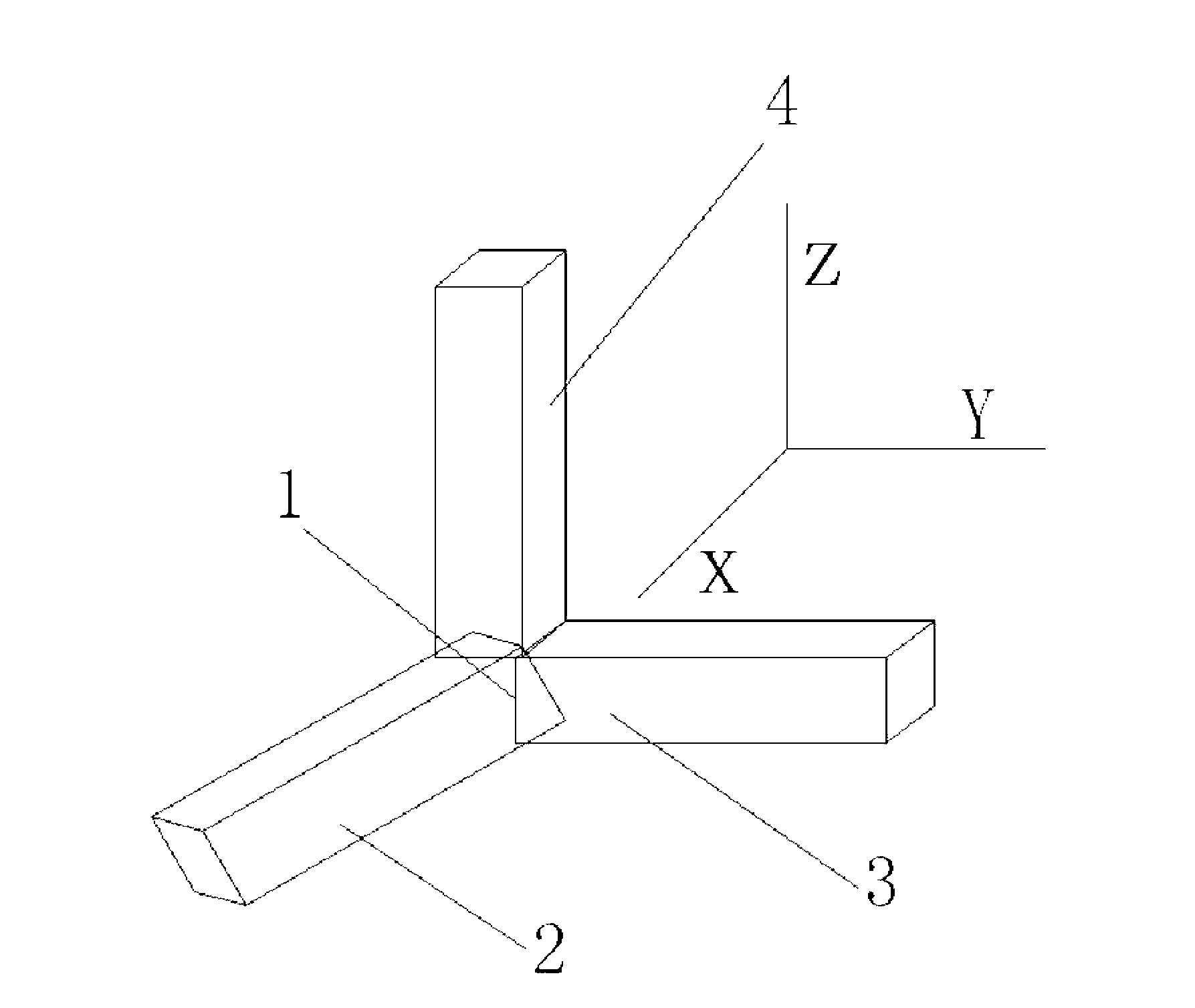

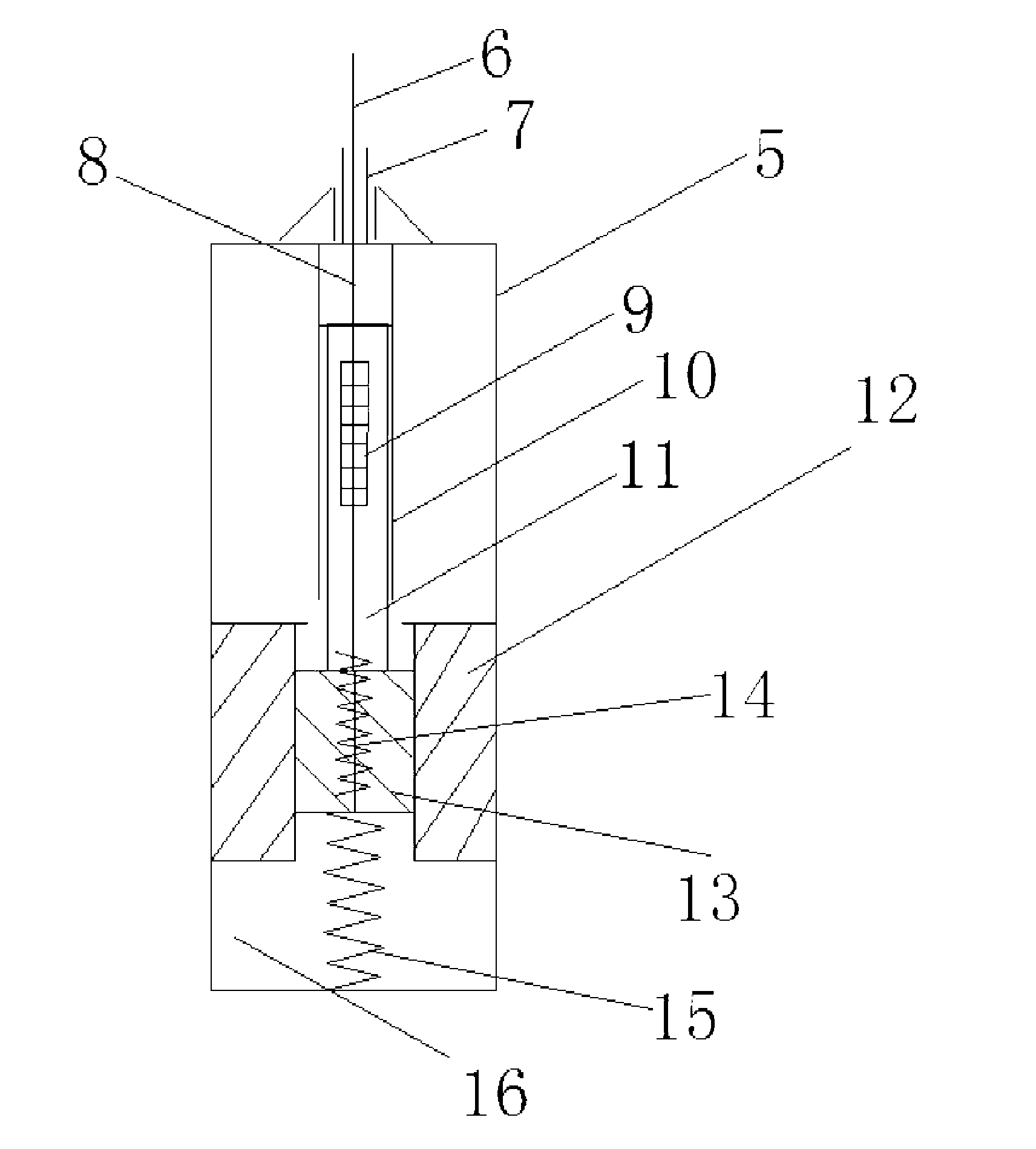

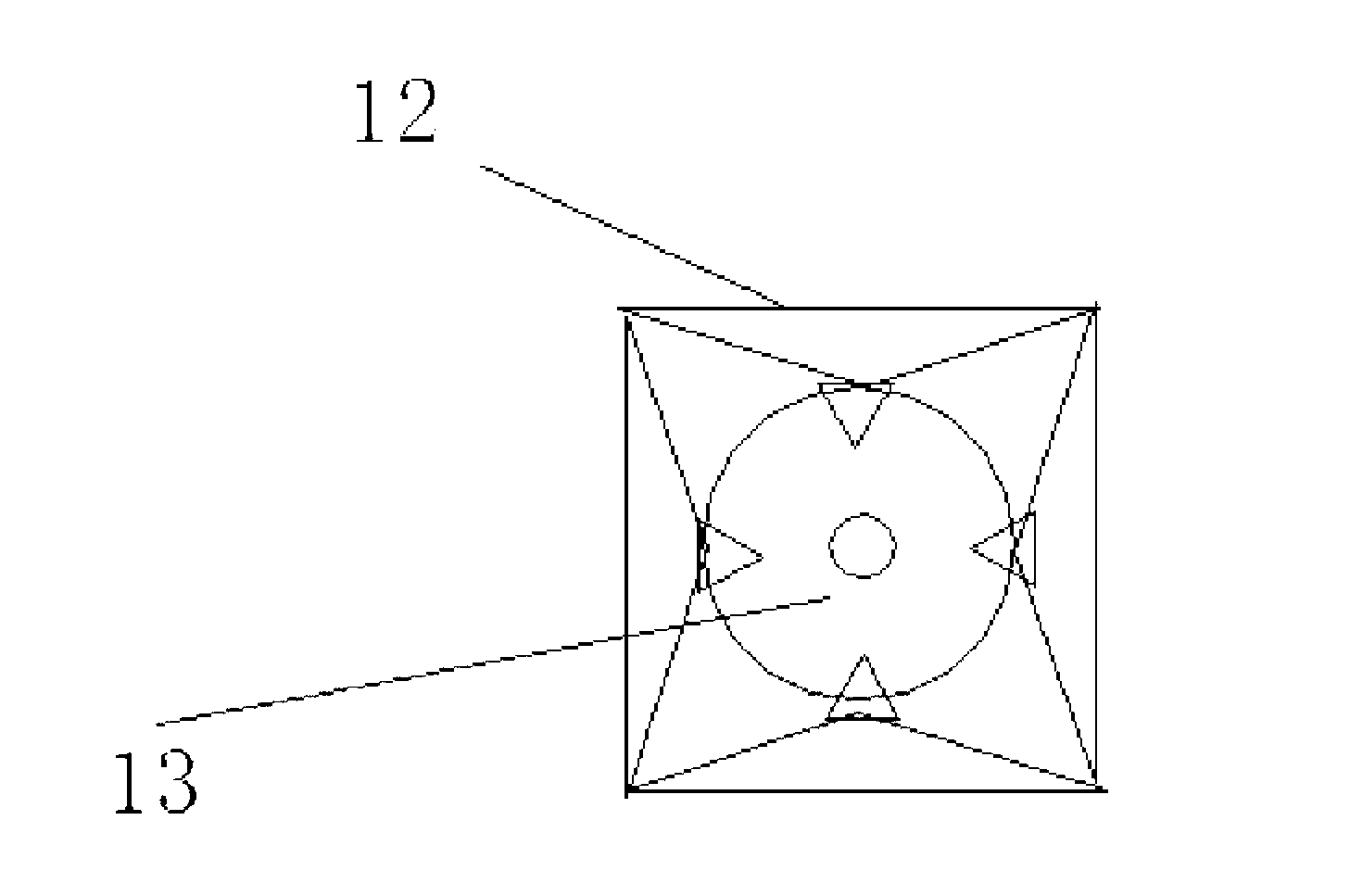

[0028] Example: such as figure 1 As shown, the X-direction sensor 2 , the Y-direction sensor 3 and the Z-direction sensor 4 are all rectangular parallelepiped, with screws at the top, which are fixed on the base 1 through threads perpendicular to each other. The sensor housing 5 is composed of two parts, the main body is a groove-like structure, the main structure of the sensor is placed inside, and the other part is a sliding cover. After the sensor is made, the sliding cover and the groove-like structure are bonded together. Such as figure 2 As shown, there is a stainless steel cylinder 10 inside the sensor housing 5 , and the inner wall of the stainless steel cylinder 10 is not in contact with the elastic material 11 coated on the outside of the fiber grating 9 . There is a round hole at the top of the housing 5 through which the transmission optical fiber 6 and the sleeve 7 pass through, and the colloid 8 bonds the transmission optical fiber 6 and the stainless steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com