Liquid filling volume verification bottle

A technology for verifying bottle and filling volume, which is applied in the direction of liquid/fluid solid measurement, volume measuring instrument/method, measuring device, etc. It can solve the problem of increasing the number of filling and sealing machine filling volume adjustments, inability to accurately display filling volume errors, and restricting detection Efficiency and other issues, to achieve the effect of accurate measurement, simple structure and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

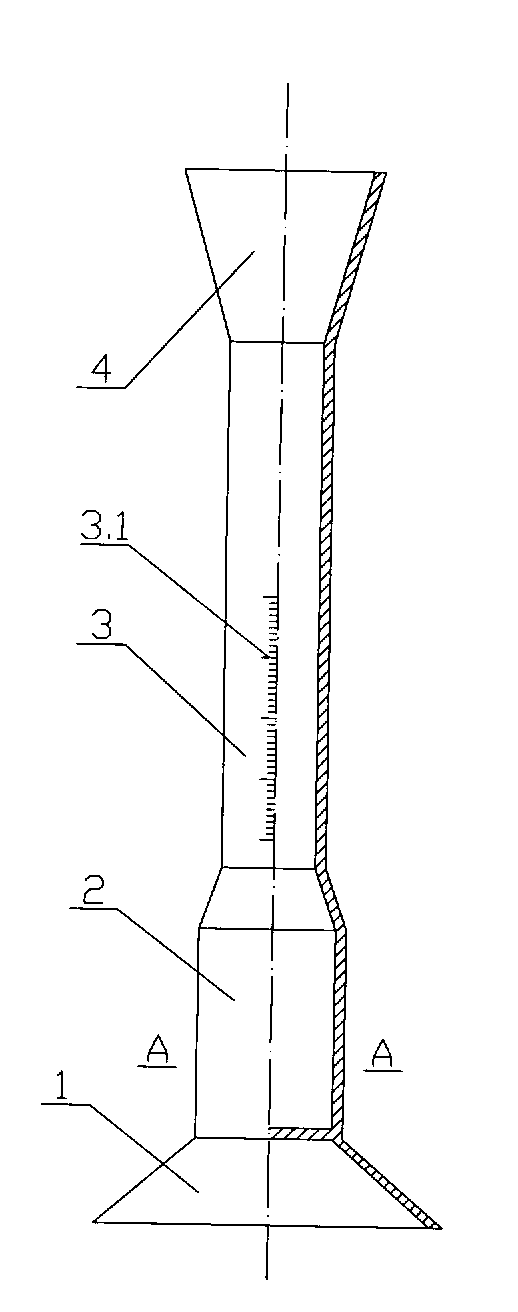

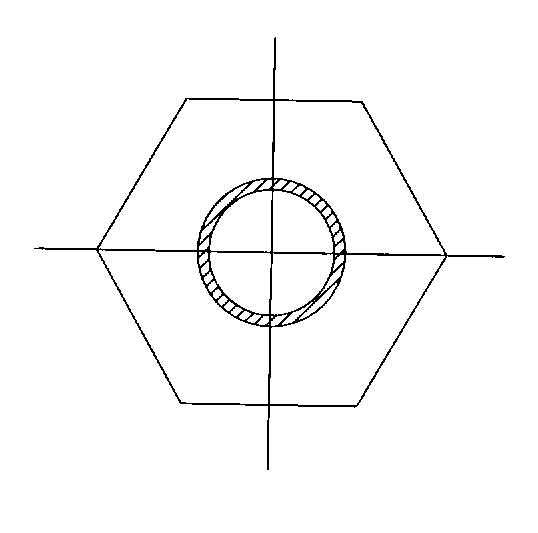

[0013] figure 1 The shown liquid capacity verification bottle with a rated capacity of 1000ml is a transparent glass container with an open structure, including a base 1, a liquid storage tube 2, a metering tube 3 and a drainage tube 4 connected sequentially from bottom to top. The drainage tube 4 is a conical tube with the large-diameter end facing upwards, and the small-diameter end communicates with the metering tube 3 and is integrally connected. The metering tube 3 is a slender circular tube structure, the lower end communicates with the liquid storage tube 2 and is integrally connected, and there is a longitudinal scale 3.1 on the tube wall; the internal capacity of the liquid storage tube 2 accounts for 70% to 85% of the rated capacity , the length of the liquid storage tube 2 is 0.5 to 0.75 times the length of the metering tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com