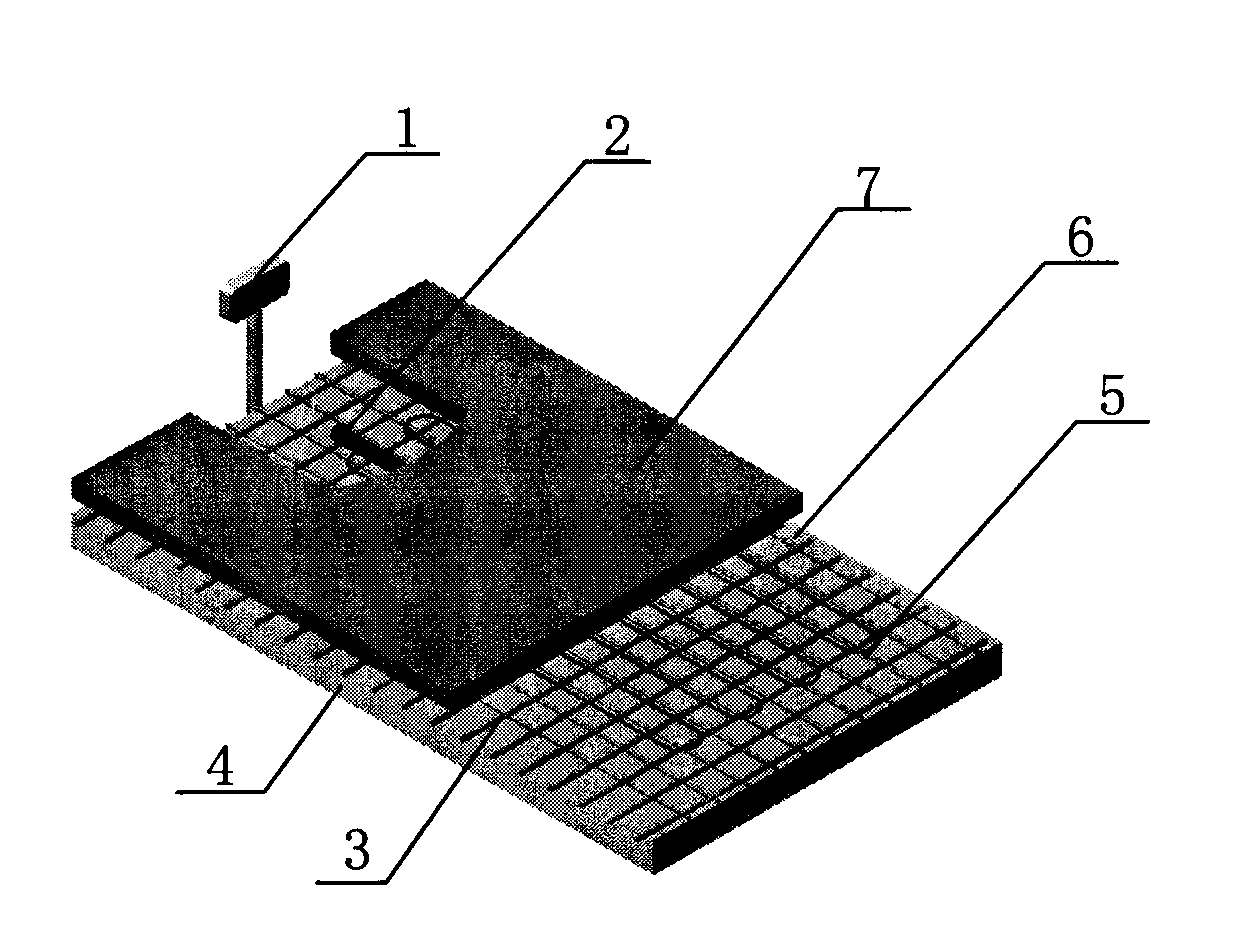

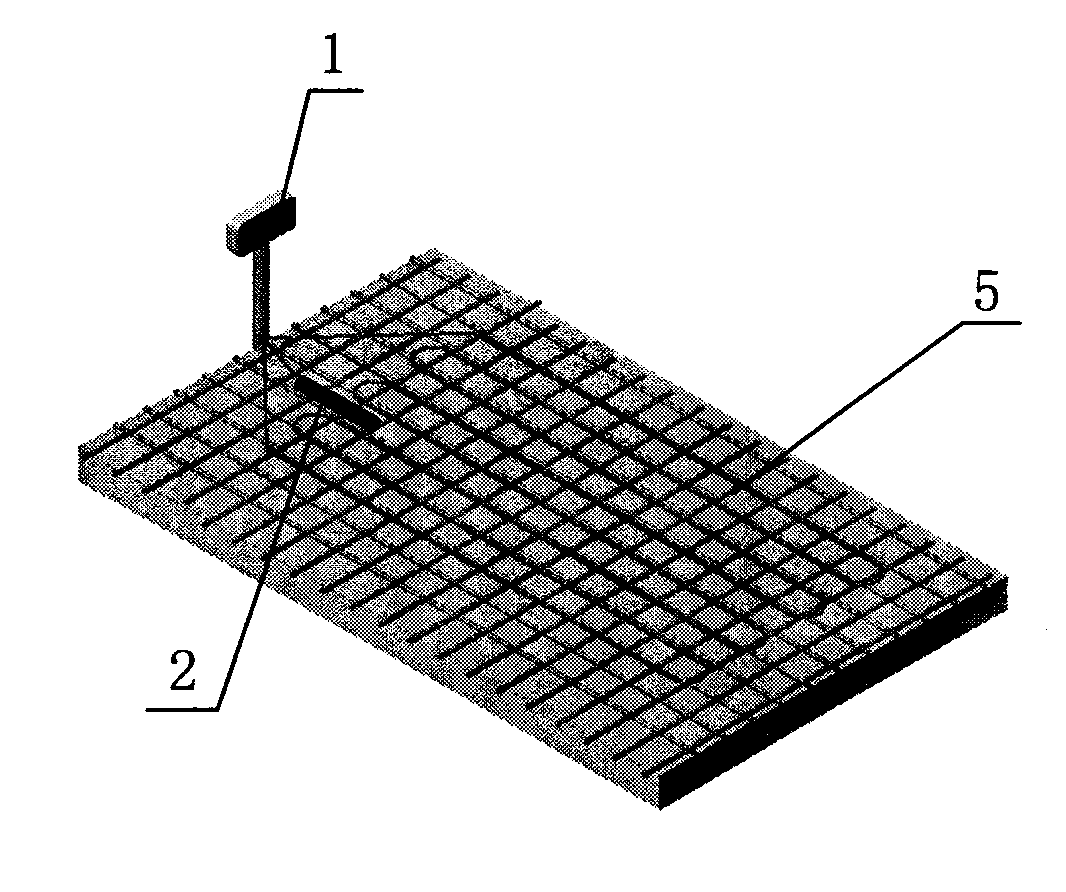

Livestock heating electric heating plate

An electric heating plate, livestock and poultry technology, which is applied in electric heating systems, animal husbandry, poultry farming, etc., can solve the problems of small concrete volume of heat preservation bed, electric heating device energized work, short heat preservation time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

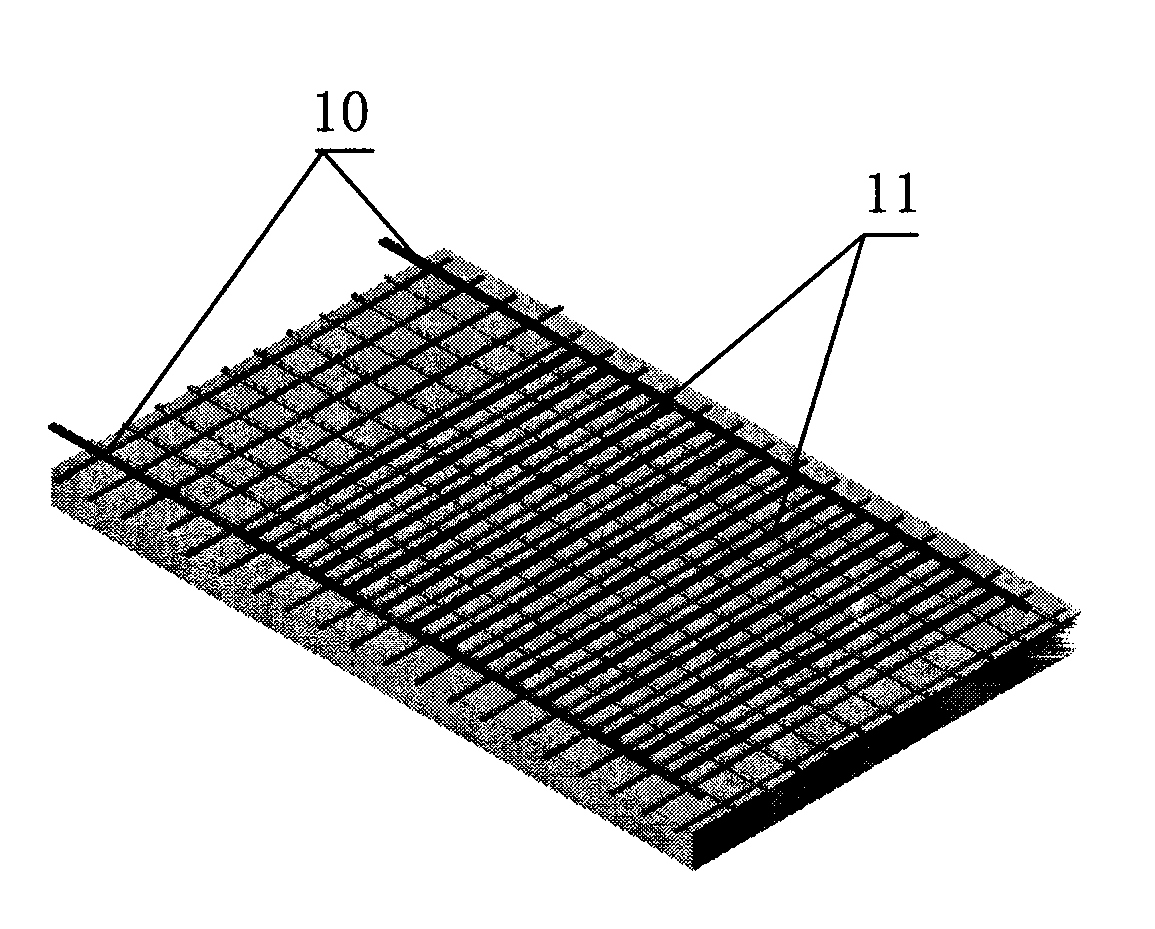

[0015] Embodiment 1 The phase change material mixed in the concrete adopts microencapsulated phase change material, and the phase change material can adopt inorganic or organic phase change material. Since the suitable temperature for heating livestock and poultry is 20-40 degrees, it is suitable for inorganic The phase change material can choose inorganic hydrated salt, for example, sodium sulfate hydrated salt (Na 2 SO 4 10H 2 O), the dodecahydrate salt of disodium hydrogen phosphate (Na 2 HPO 4 12H 2 O) and the hydrated salt of calcium chloride (CaCl 2 ·6H 2 (2) etc., although inorganic hydrated salts are cheap in cost, supercooling and precipitation are ubiquitous, so preferably adopt organic phase-change materials, organic phase-change materials can adopt paraffins, higher fatty acids and alcohols etc., and paraffins can adopt commodity The phase change materials, such as the phase change energy storage material wax produced by Sinopec Nanyang Paraffin Fine Chemical...

Embodiment 2

[0016] Embodiment 2 In view of the high cost of the microcapsule phase change material, the phase change material is adsorbed in the porous material by means of adsorption, and the phase change material is fixed in the pores by using the porosity and capillary adsorption force of the material. Porous perlite or diatomaceous earth can be selected as the adsorption material. Add perlite or diatomite and phase change material paraffin into a vacuum container with a heating and stirring device. The heating temperature exceeds the melting temperature of the phase change paraffin. Make the paraffin fully enter the micropores of the adsorption material, the weight of the adsorption material to absorb the paraffin is 40%-65%, and the seepage ratio of the paraffin is less than 15% as the boundary. Due to the low thermal conductivity of the adsorption material and paraffin, a graphite heat-conducting material can be added to enhance the thermal conductivity of the paraffin, and the added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com