Subspace identification based forecasting method for superheated steam output of boiler of firepower power station

A technology of subspace identification and superheated steam, which is applied in steam generation, lighting and heating equipment, control systems, etc., can solve problems such as low dynamic accuracy, failure to consider the influence of temperature and pressure information, and inability to guarantee the continuity of model identification data, etc. Achieve the effects of improving model accuracy, improving forecast accuracy, and fast model speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

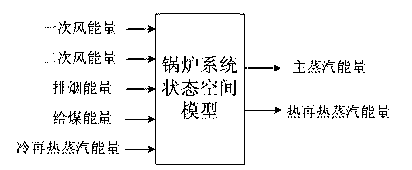

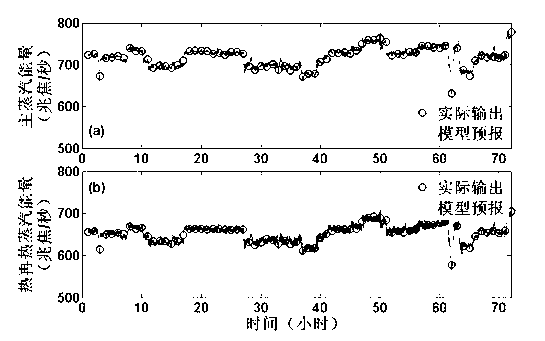

Method used

Image

Examples

Embodiment

[0027] The operation of the thermal power plant boiler in this embodiment needs to meet the following conditions:

[0028] A. Boiler production is approximately a linear process in a short period of time;

[0029] B. The primary / secondary air volume, induced air volume, and furnace pulverized coal feeding volume are all in manual open-loop control mode;

[0030] C. All control signals are continuously motivated;

[0031] D. The control signal and process random noise are uncorrelated;

[0032] E. The amount of measurement data collected and stored on site is sufficient;

[0033] The steps of this embodiment are as follows:

[0034] Step 1: Establish OPC data communication with the plant-level DCS configuration software, and collect production data every 5 seconds online. The obtained measurement point information mainly includes: unit load, coal feeding rate of coal feeder, primary / secondary air flow, Boiler operating parameters such as pressure and temperature, flue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com