Negative pressure adjusting device for inlet of compressor with variable diameter

An adjustment device and compressor technology, applied in the field of machinery, can solve problems such as low control accuracy and clumsy adjustment method of imported negative pressure, and achieve the effect of reducing air intake resistance and eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific examples of the present invention, and the implementation of the present invention will be further described in conjunction with the accompanying drawings.

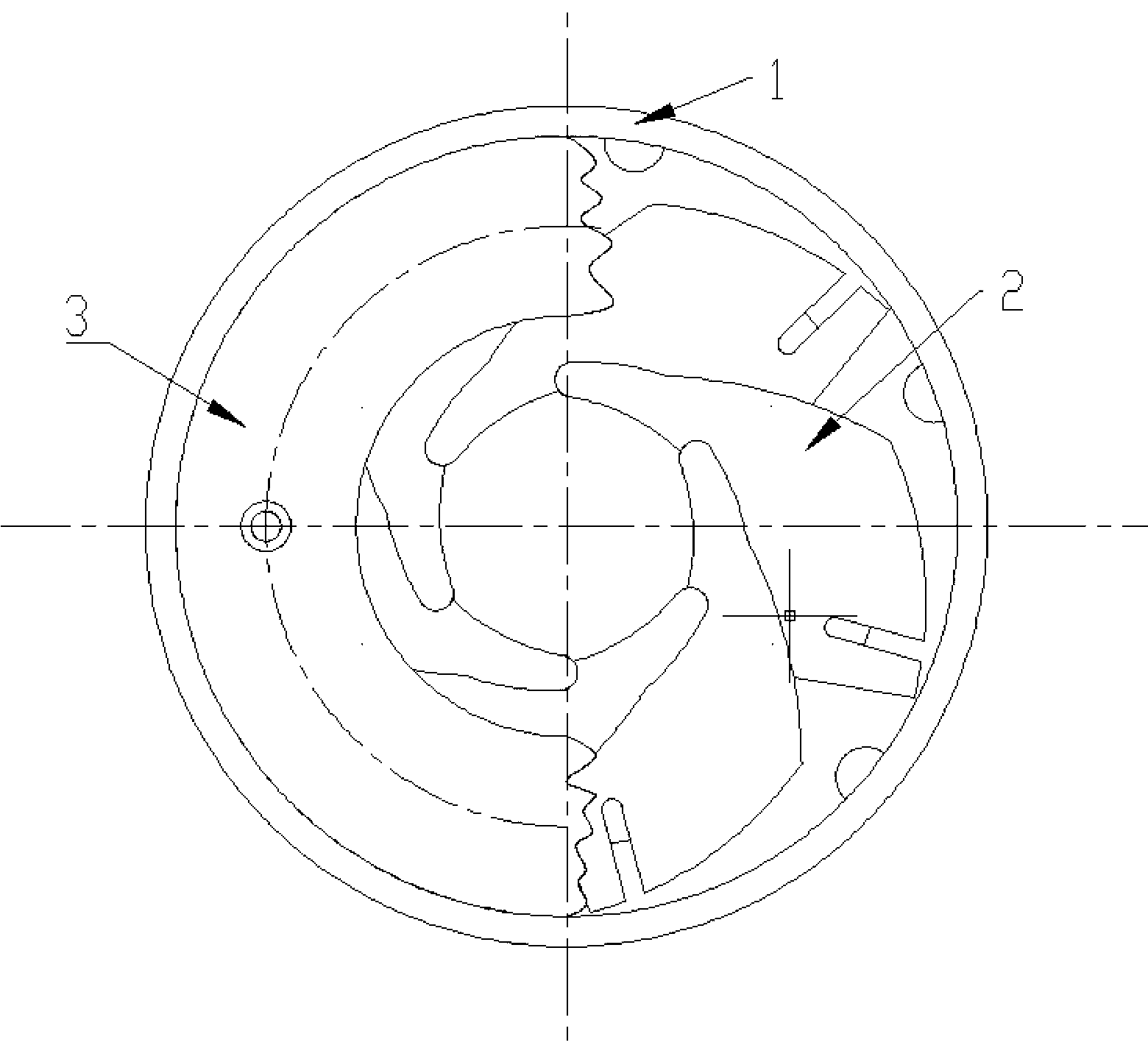

[0022] Such as figure 1 Shown, the present invention is mainly made of fixed frame 1, blade 2 and manipulation device 3.

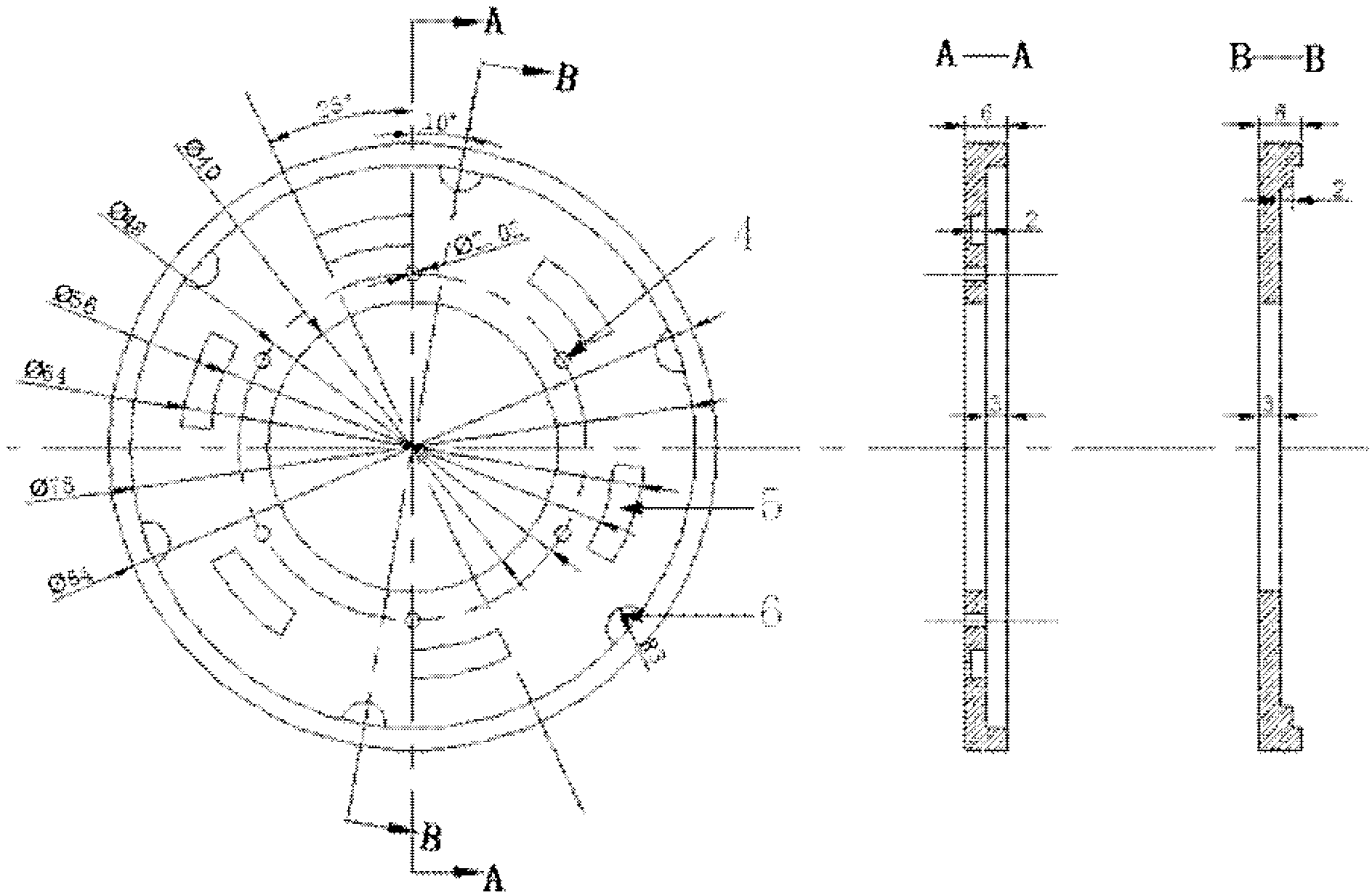

[0023] Such as figure 2 As shown, the fixed frame is a groove-shaped frame with a hollow aperture in the center. In this embodiment, the outer diameter of the fixed frame is 84mm, the inner diameter is 40mm, and the wall thickness of the frame is 3mm. From the aperture to the inside of the groove on the outer edge of the fixed frame, 6 sets of blade rotating shaft positioning holes 4 and toggle shaft guide grooves 5 are drilled radially. The 6 blade rotating shaft positioning holes are evenly distributed on the center of the fixed frame. On a circle with a diameter of 48mm, the diameter of each positioning hole is 2.02mm. The guide groove is fan-shaped, the diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com