Salt-manufacturing method from bittern in solar greenhouse

A solar greenhouse and brine technology, applied in the direction of alkali metal chloride, etc., can solve the problems of increasing the halogen temperature, and achieve the effect of saving energy, protecting the environment and excellent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

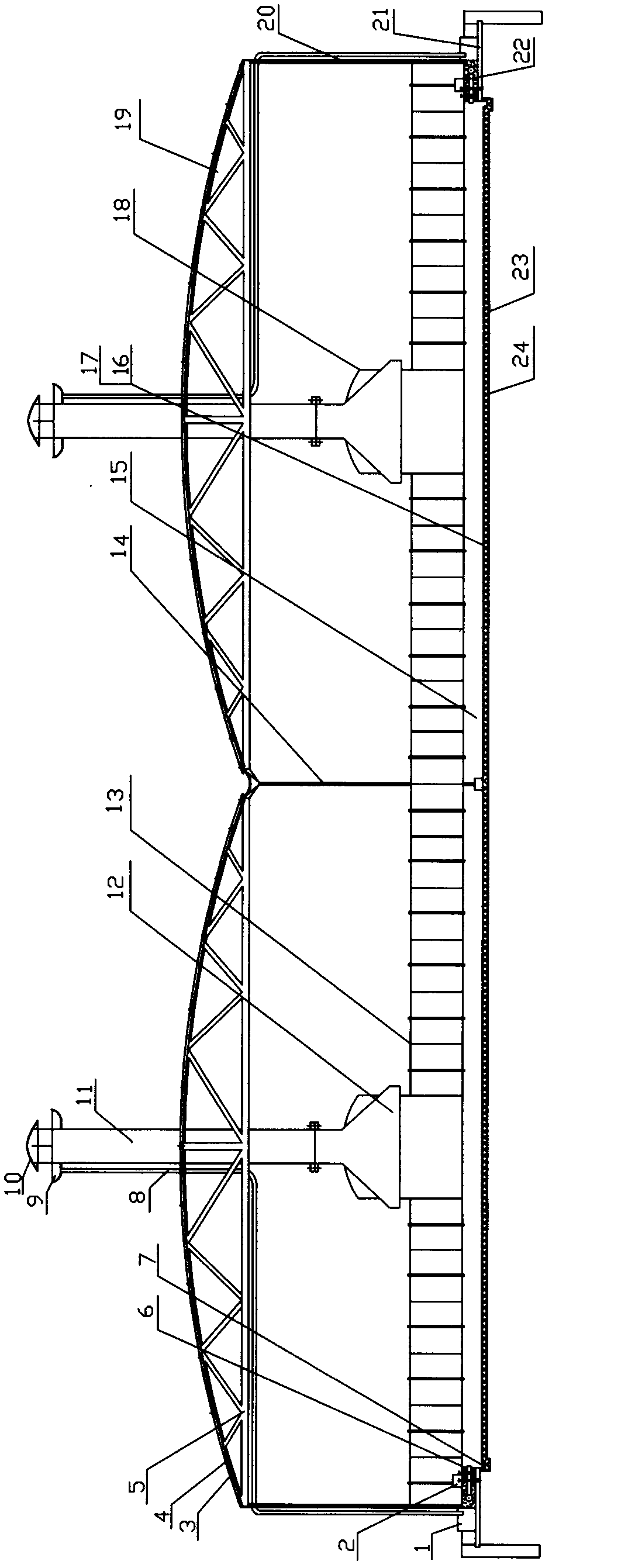

[0028] A method for making salt from brine in a solar greenhouse, comprising making brine, filling ponds, crystallizing, and collecting salt, using brine as a raw material, using a solar greenhouse as a salt making device, and completing the projects of evaporation, crystallization, and salt collection of brine in the solar greenhouse, It can produce high-quality industrial salt, sun-cured refined salt, sun-cured salt and low-sodium salt all year round.

[0029] Build a qualified solar greenhouse, the upper part of its structure is a plastic greenhouse, and the lower part is a crystallization pond 15; the plastic greenhouse is covered above the crystallization pond 15, and is located on the concrete foundation around the crystallization pond 15, and a fixed support 5 is set up in the greenhouse. The fully transparent plastic film 3 is sealed, and the plastic film 3 is pasted on the outside of the fixed bracket 5 through a slot or glue and riveted by rivets 4. Floor windows 13 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com