Device for carrying out hot stamping for multiple times on one impression roller

An embossing roller and the same technology, which is applied to the field of multiple bronzing devices, can solve problems such as waste of resources, and achieve the effects of reducing floor space, reducing costs, and improving the accuracy of bronzing and overprinting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

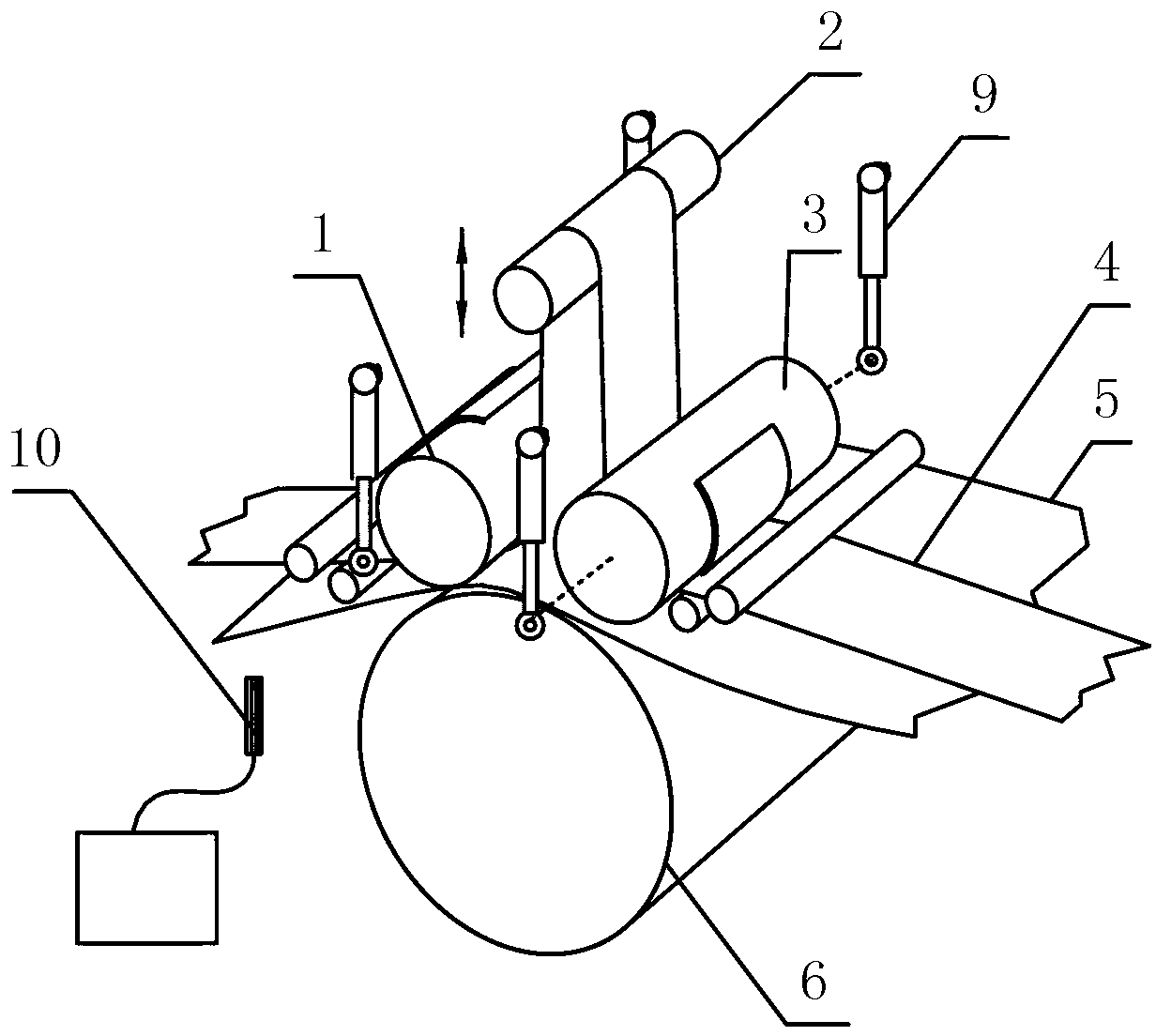

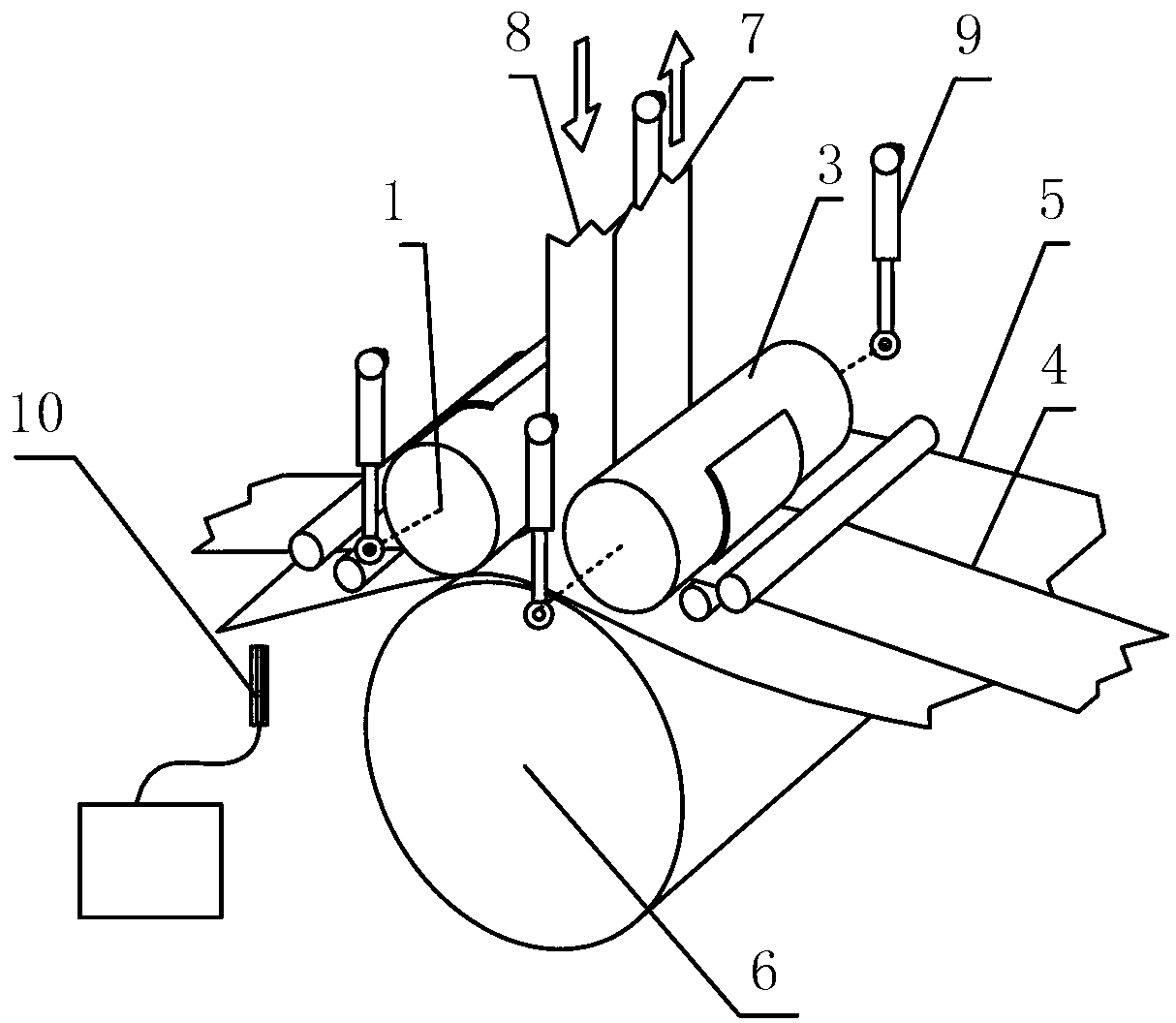

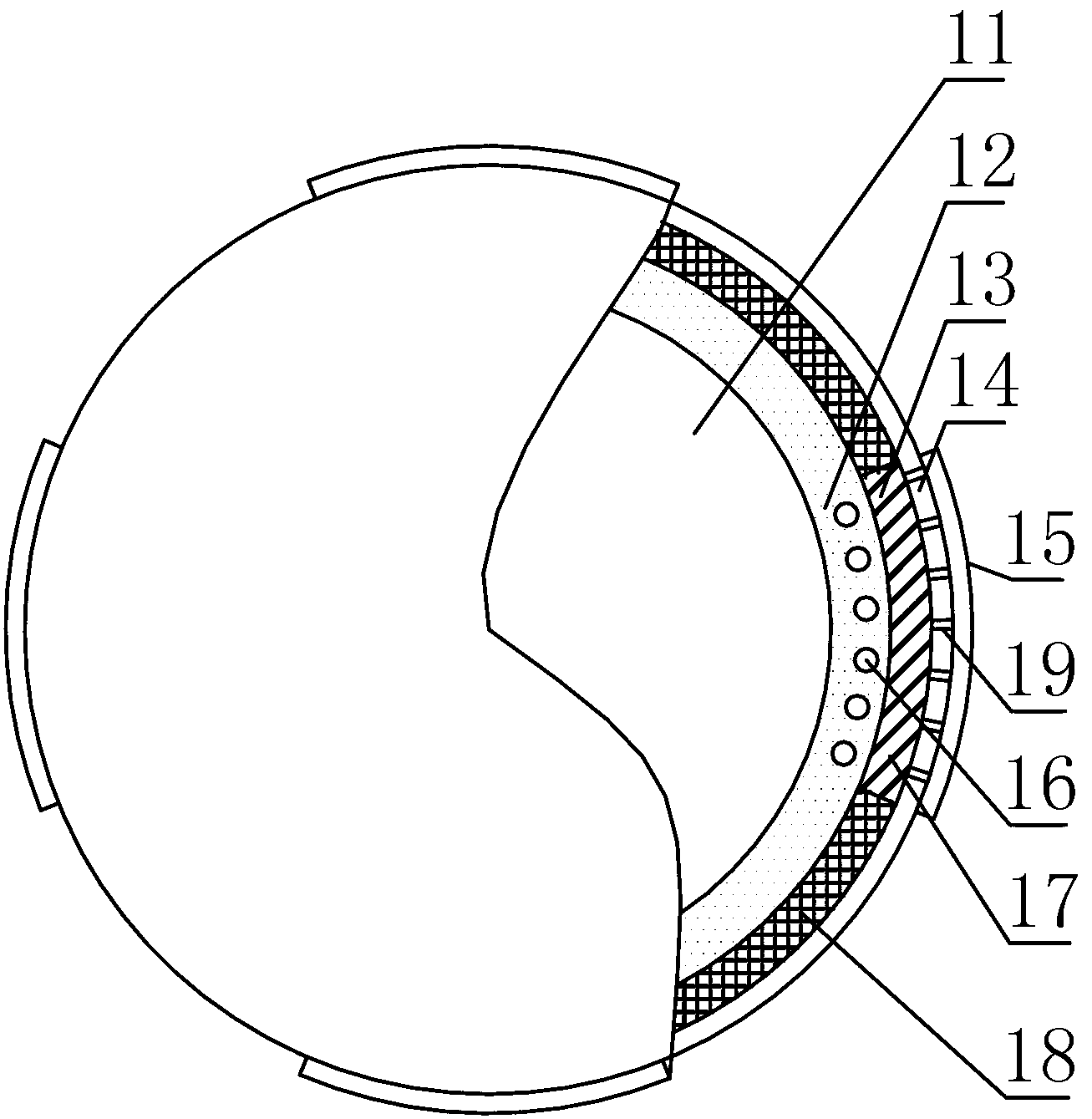

[0018] Below in conjunction with accompanying drawing, the present invention is further described: as Figures 1~4 As shown in , the device for repeatedly hot stamping on the same embossing roller includes an embossing roller 6, at least a plurality of hot stamping rollers with a front hot stamping roller 3 and a rear hot stamping roller 1 in the same imprinting unit. A plurality of hot stamping rollers are stamped by the same embossing roller 6; an ultrasonic micro-humidification device 10 is arranged behind the hot stamping roller; and the fixed layer 14; the heating layer 12 is provided with an electric heating member 16 at the position corresponding to the hot stamping plate 15, and the thermal conductive layer 13 is provided with a heat conduction area 17 and a heat insulation area 18, and the heat conduction area 17 is located at the lower position of the bronzing plate 15 , outside the heat-conducting area 17 of the heat-conducting layer is the heat-insulating area 18 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com