Tea frying machine

A technique for frying tea machines and woks, which is applied in the field of tea frying machines and can solve the problems of poor versatility and single types of tea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

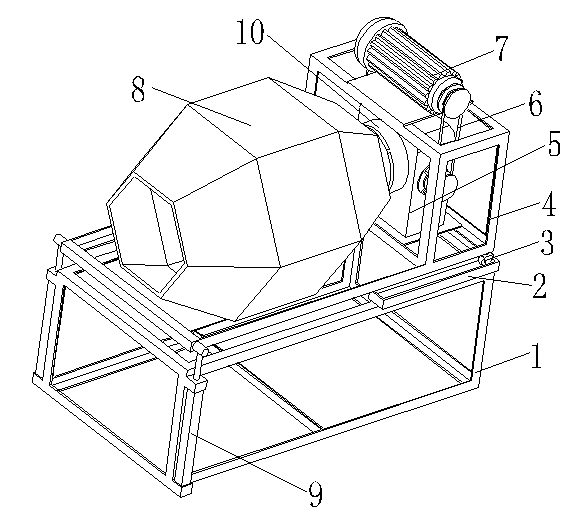

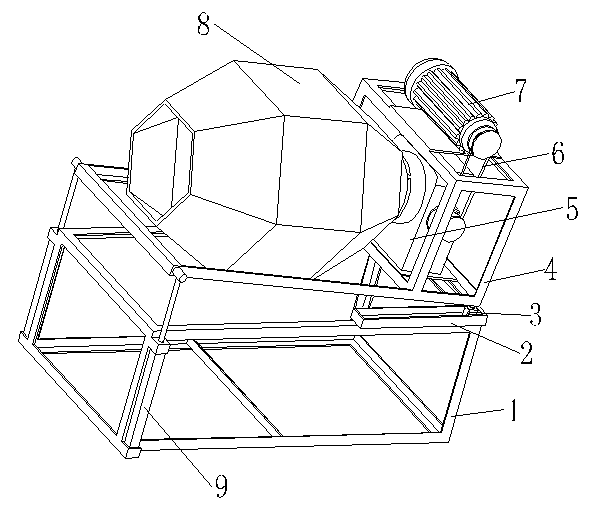

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] as attached figure 1 , 2 Shown is a tea frying machine according to the present invention, comprising a base 1, a bracket 4, a governor 5, a motor 7, a frying pan 8, a cylinder 9, a chute 2, wheels 3, a belt 6, and a main shaft 10; The upper surface of the base 1 is provided with a chute 2; the lower end of the support 4 is provided with two wheels 3; the wheels 3 on the support 4 are stuck in the chute 2 and can move along the chute 2; The cylinder 9 is arranged on both sides of the base 1; the top of the cylinder 9 is connected to the bracket 4; the motor 7 is arranged on the upper end of the bracket 2; The rotating speed of pot; Described belt 6 connects motor 7 and governor 5; Described wok 8 is connected on the governor 5 by main shaft 10 and the axis of main shaft 10 and the axis of wok 8 are positioned on the same straight line; When the inclination angle of the axis of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com