Organic light-emitting diode (OLED) packaging structure, manufacturing method thereof and luminescent device

A technology of packaging structure and manufacturing method, which is applied in the manufacture of semiconductor devices, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of OLED observation angle dependence, achieve the effect of reducing observation angle dependence and enhancing the ability to scatter light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the OLED packaging structure, manufacturing method and light-emitting device provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

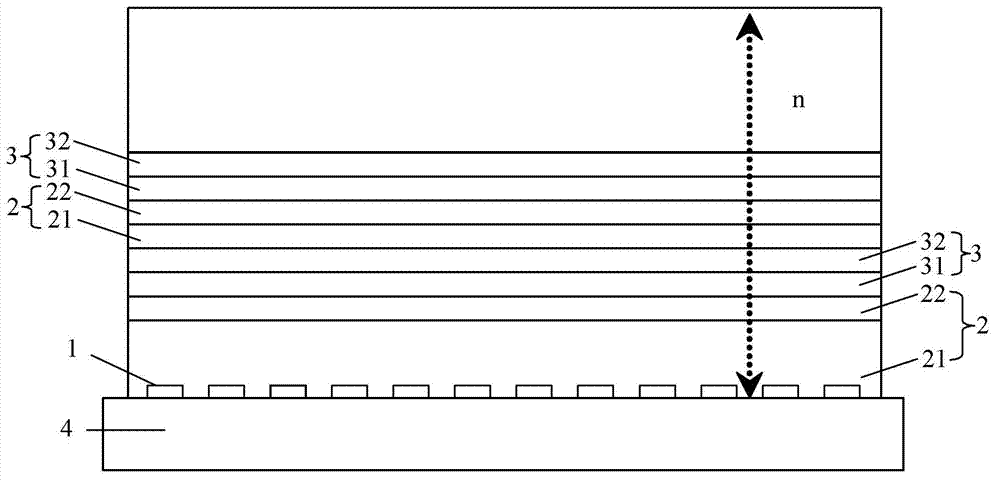

[0045] figure 1 This is a schematic structural diagram of an OLED packaging structure provided by Embodiment 1 of the present invention, such as figure 1 As shown, the OLED packaging structure may include: a base substrate 4, an OLED 1, a barrier layer 2 and an optical modulation layer 3, and the barrier layer 2 and the optical modulation layer 3 are alternately formed on the OLED 1.

[0046] In this embodiment, preferably, the barrier layer 2 and the optical modulation layer 3 can be alternately formed on the OLED 1 according to the number of alternating periods, and the optical modulation layer 3 is located on the barrier layer 2 in each alternating period. That is, on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com