Outgoing line via overlap structure of capacitive touch screen and production method of outgoing line via overlap structure

A technology of capacitive touch screen and manufacturing method, which is applied in the input/output process of data processing, electrical digital data processing, instruments, etc., can solve the problems of low yield, affect visual effects, and high cost, and reduce the number of lead wires and reduce Process difficulty and the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

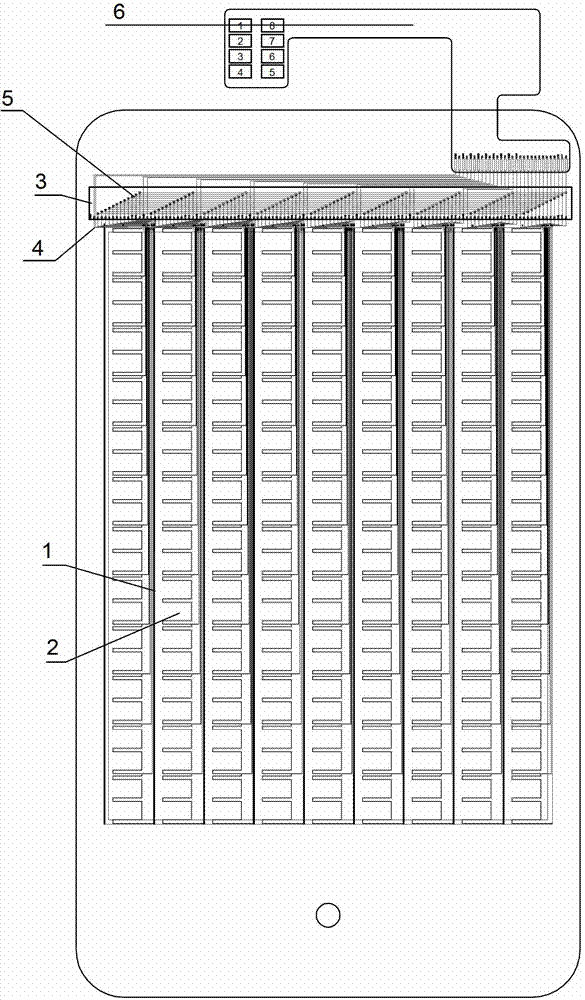

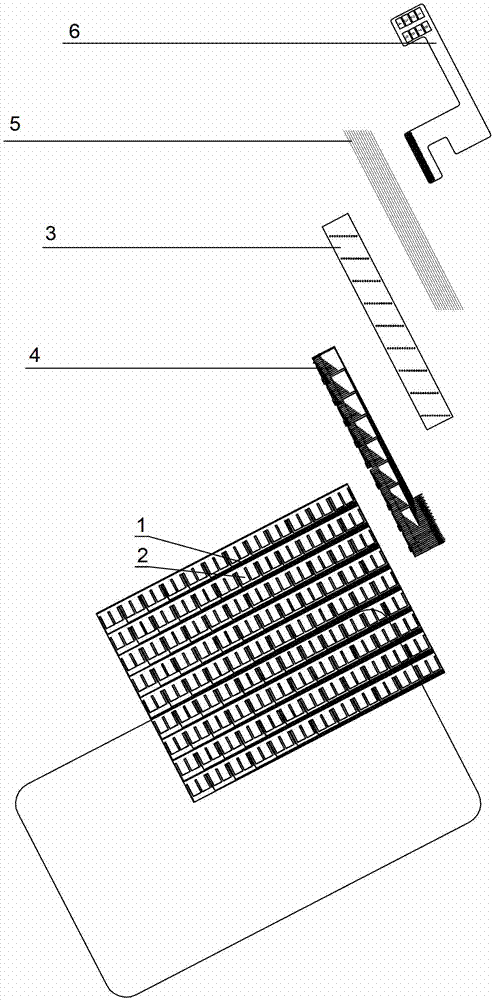

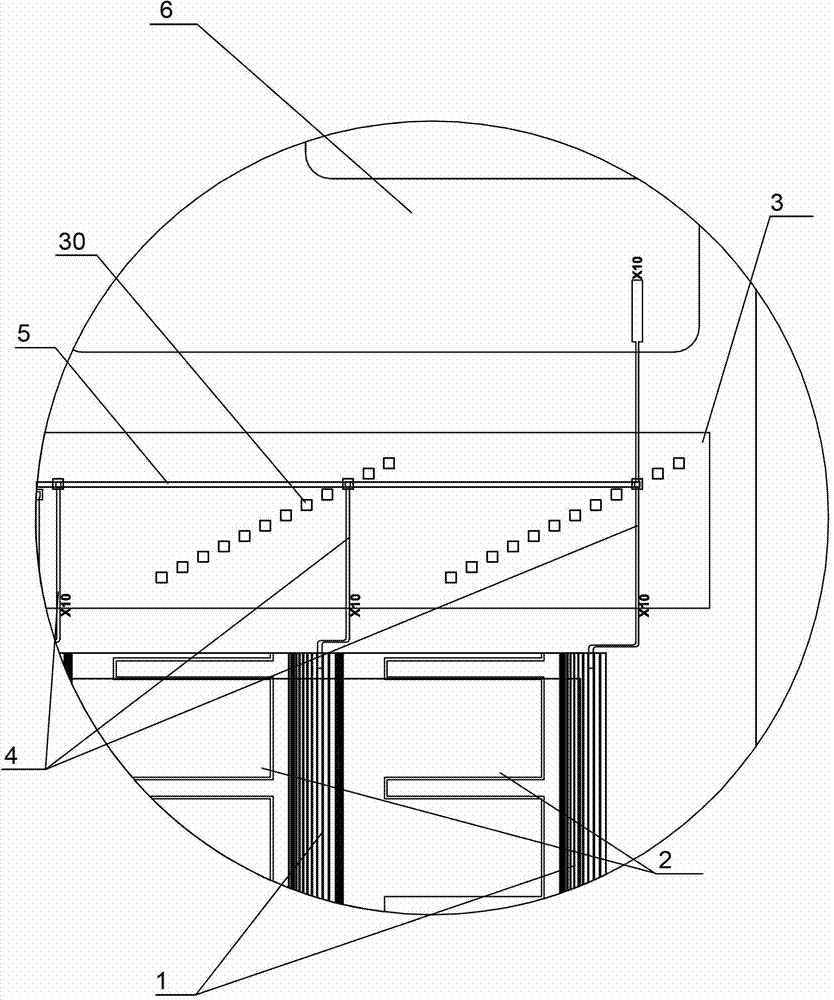

[0027] Refer to attached picture. The touch functional area of the capacitive touch screen of the present invention adopts a single-layer structure, and the lead-out line of the sensing layer pattern 1 uses the insulating layer 3 and the wire 5 to realize the lead-out line via hole overlap, and the insulating layer 3 is connected to the lead-out line of the sensing layer pattern. A blank area 30 is reserved at the overlapping position of the line 4 and the conductive wire 5, and a blank area 30 corresponds to the overlapping of a lead-out line 4 of an induction layer pattern and a lead-out line 5, and the lead-out line 5 and the lead-out line 4 of the induction layer pattern are placed On both sides of the insulating layer 3 , the blank area 30 reserved by the insulating layer 3 is used for overlapping conduction.

[0028] The single-layer structure is that the sensing layer pattern 1 and the driving layer pattern 2 are in the same conductive layer.

[0029] There are n gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com