Testing device for vertical and continuous loading at optional position of numerical control moving table

A technology of mobile workbench and test device, which is applied in the direction of measuring device, machine/structural component test, instrument, etc. It can solve the problems of material consumption, inability to achieve continuous loading, and inability to achieve vertical loading value, etc., to achieve accurate loading force The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

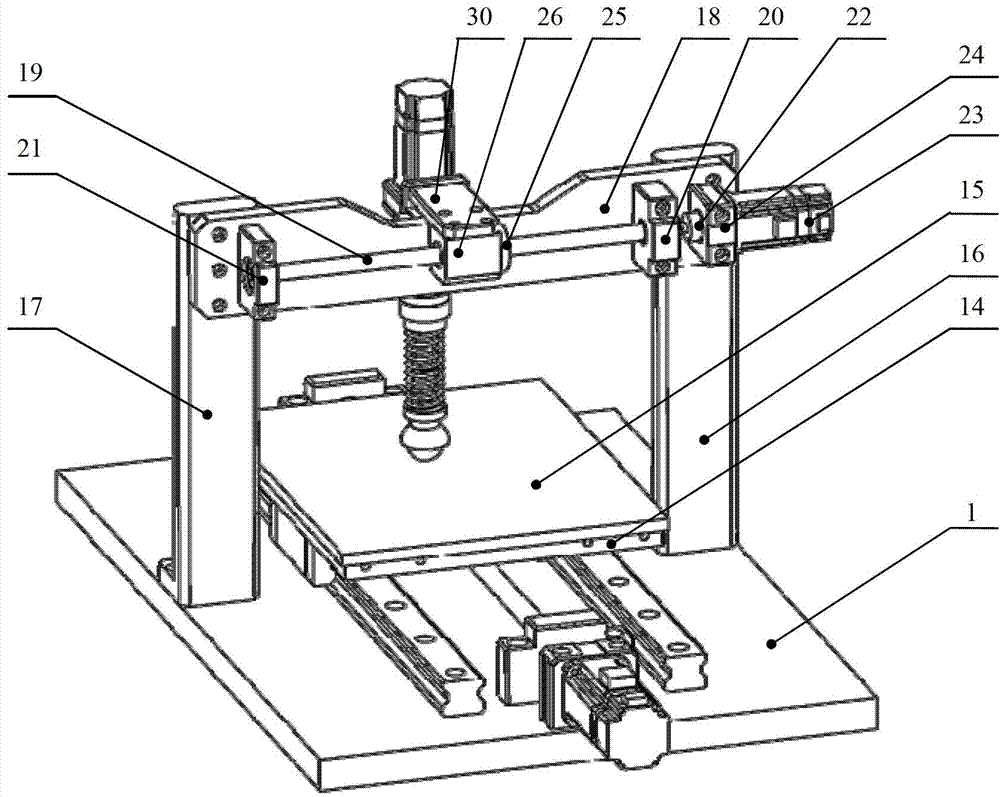

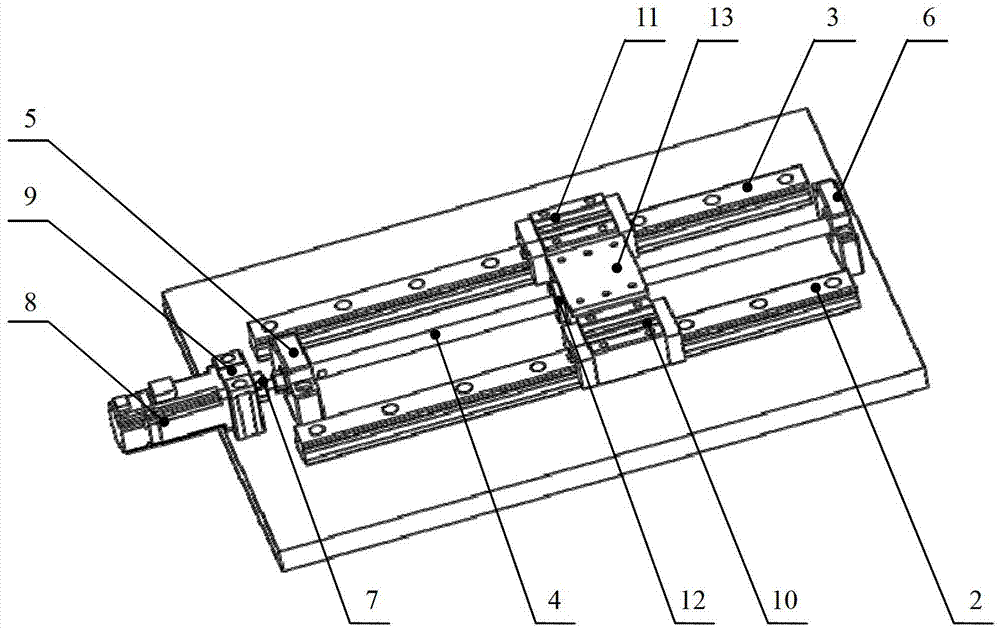

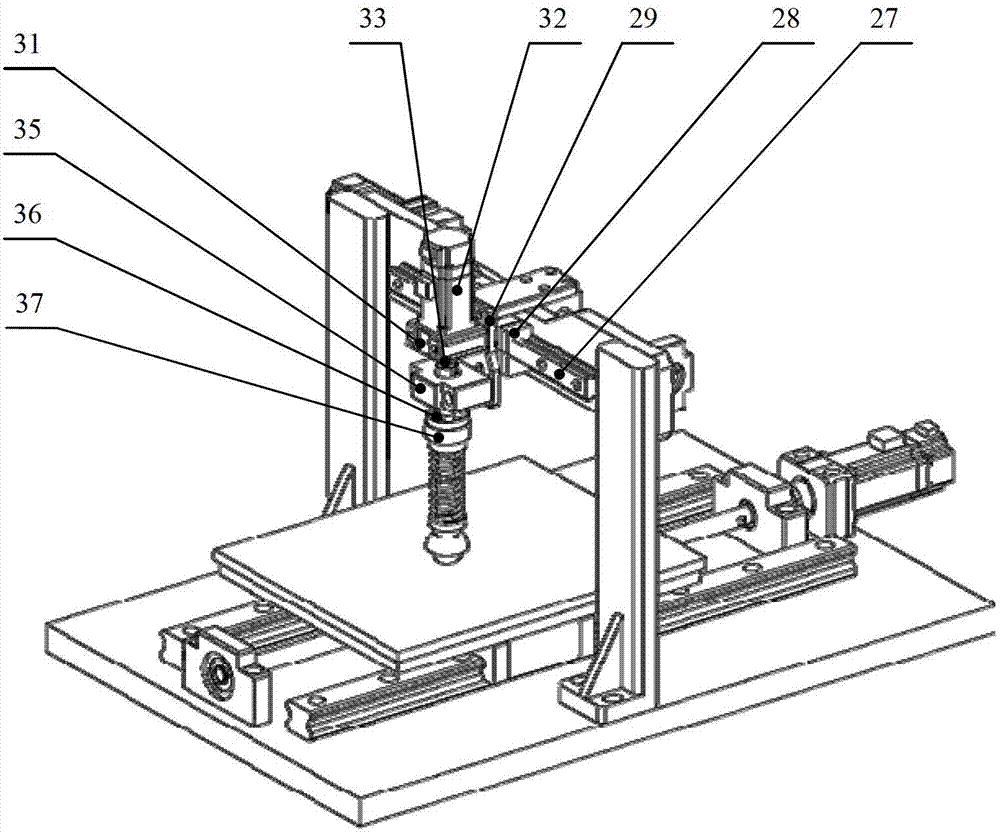

[0022] Below in conjunction with accompanying drawing, the test device that realizes vertical continuous loading at any position of the numerically controlled mobile workbench that the present invention proposes is described in detail:

[0023] Such as figure 1 and figure 2 As shown, the structure of the simulated numerically controlled mobile workbench of the present invention is: on the base 1, parallel first sliding guide rails 2 and second sliding guide rails 3 are arranged; A first ball screw 4 is arranged in parallel in the middle of the guide rail 3; the first ball screw 4 is supported by the first ball screw fixed support seat 5 and the first ball screw floating support seat 6 fixed on the base 1, and is The protruding end of a ball screw fixed support base 5 is directly connected with the first servo motor 8 through the first coupling 7, and the first servo motor 8 is fixed on the base 1 through the first motor seat 9; A first slide block 10 is arranged on a slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com