Seal testing device for automobile clutch booster

A seal detection and clutch technology, applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc., can solve the problems of affecting the detection quality, low work efficiency, high labor intensity, etc., to improve the detection quality, high work efficiency, reduce Detect the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

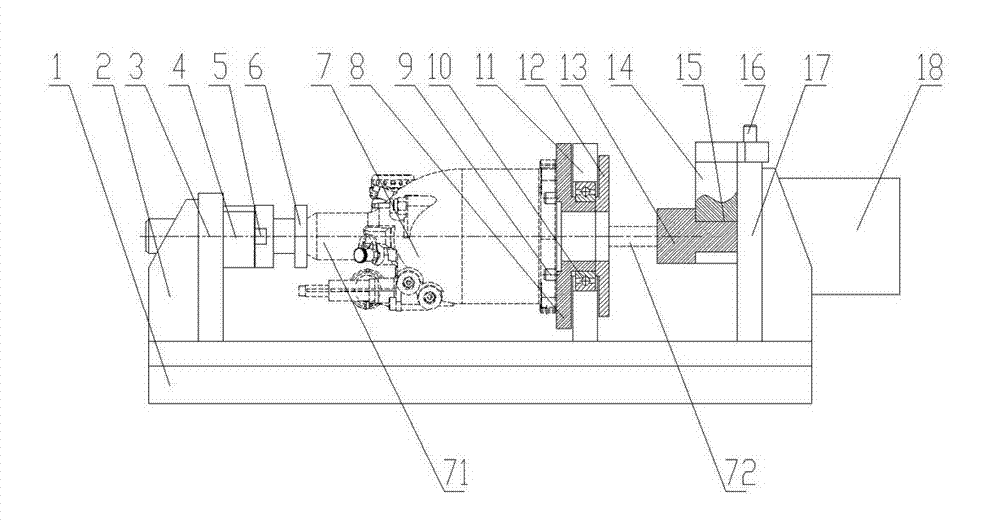

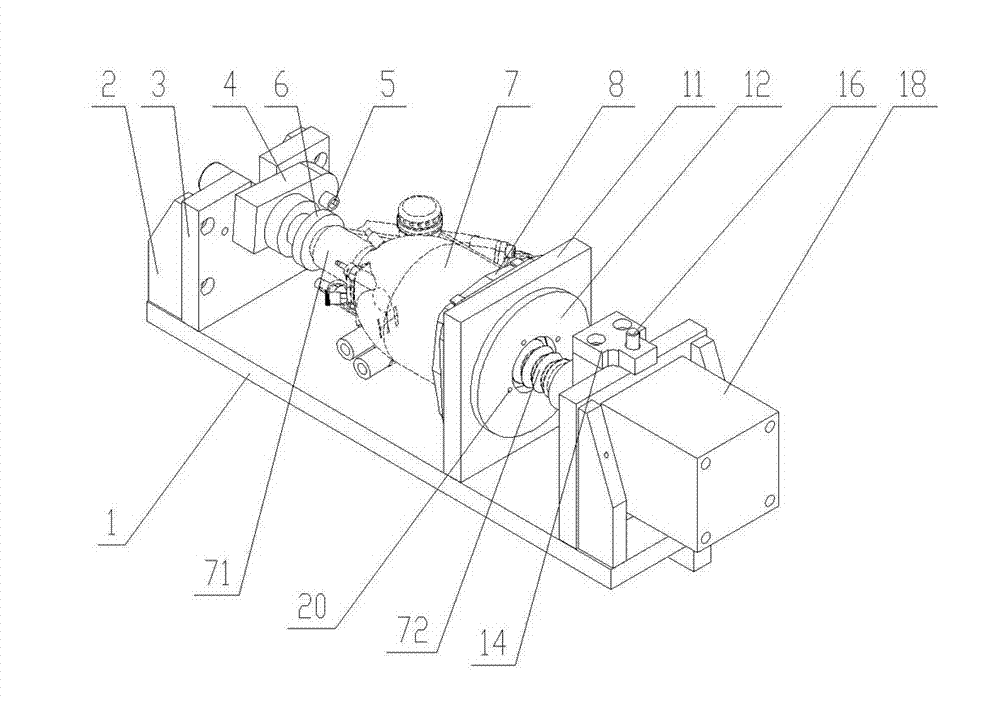

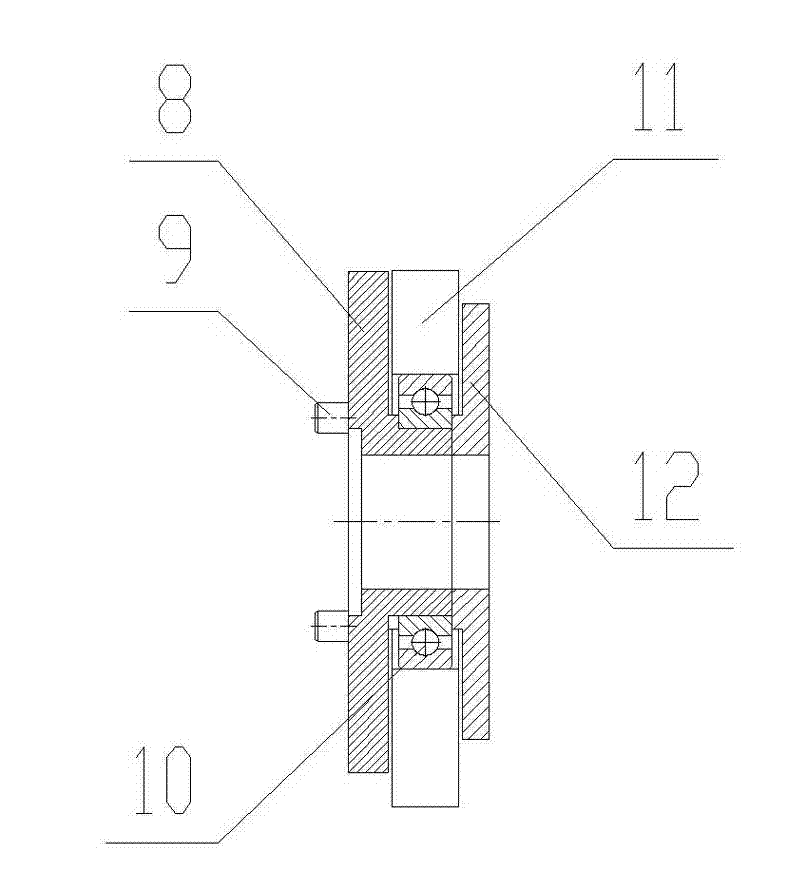

[0018] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a sealing detection device for an automobile clutch booster includes a base plate 1 and a cylinder 18, the base plate 1 is provided with a joint limiting plate 3 and a cylinder mounting plate 17, and the joint limiting plate 3 and the cylinder mounting plate 17 are respectively provided with reinforced Rib 2, the cylinder 18 is located on one side of the cylinder mounting plate 17, the output shaft of the cylinder is connected to the top 13, the top 13 passes through the cylinder mounting plate 17, and the bottom plate 1 between the joint limit plate 3 and the cylinder mounting plate 17 is provided with a bearing The bearing seat 11 of 10 is provided with a perforated rotating positioning plate 8 installed on the bearing seat 11, the rotating positioning plate 8 is provided with a cylindrical surface that is interference fit with the inner ring of the bearing 10, and the other end surface of the bearing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com