Method and device for producing lattice points of diffusion plate of light-emitting diode (LED) backlight module

A technology of backlight module and generating device, which is applied in the direction of lighting devices, lighting device components, light sources, etc., can solve the problem of high cost of opening, and achieve the effect of improving development speed and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

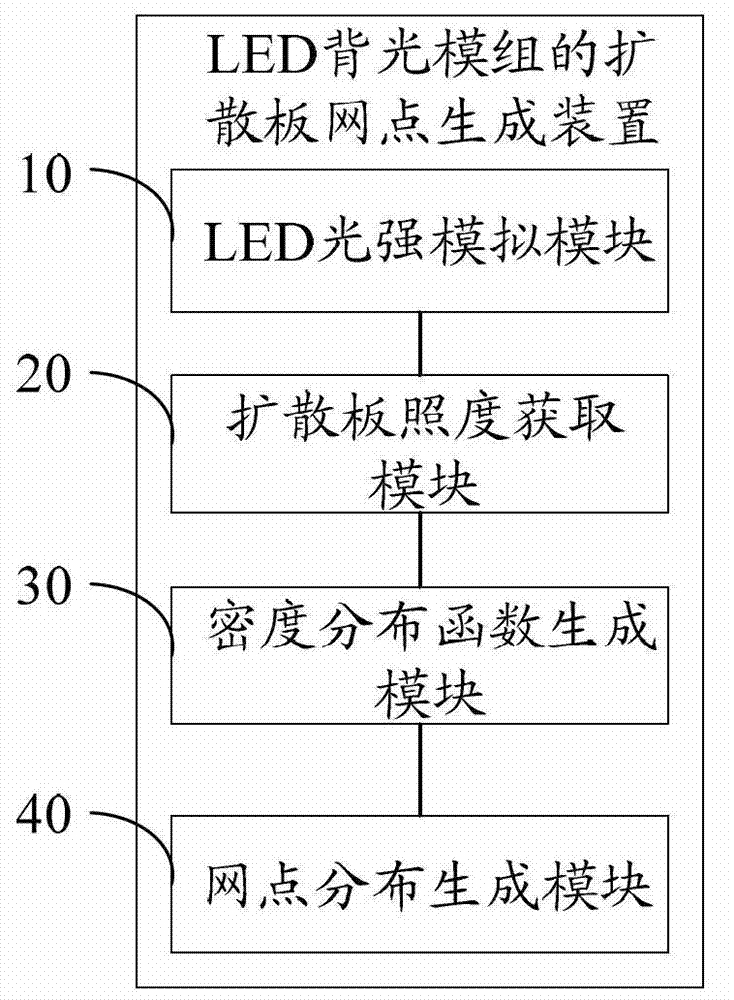

[0069] refer to figure 1 , the present invention provides a diffusion plate dot generation device for an LED backlight module, which includes:

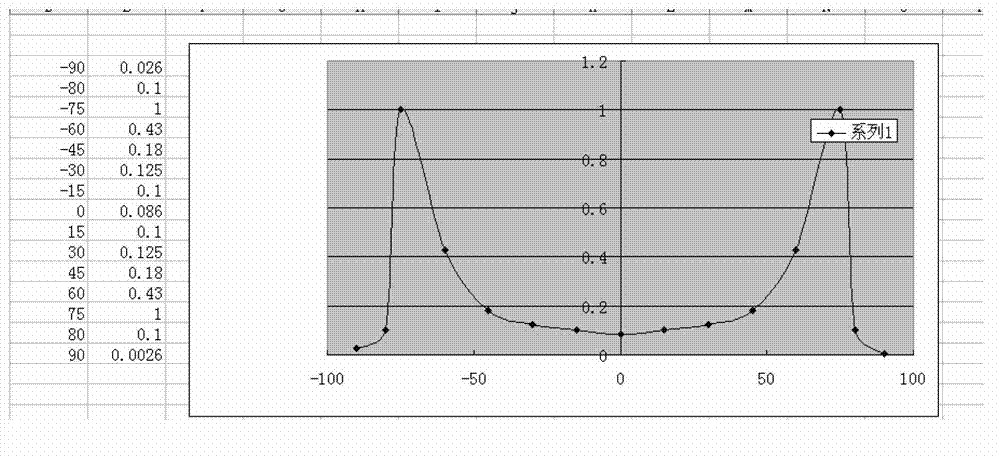

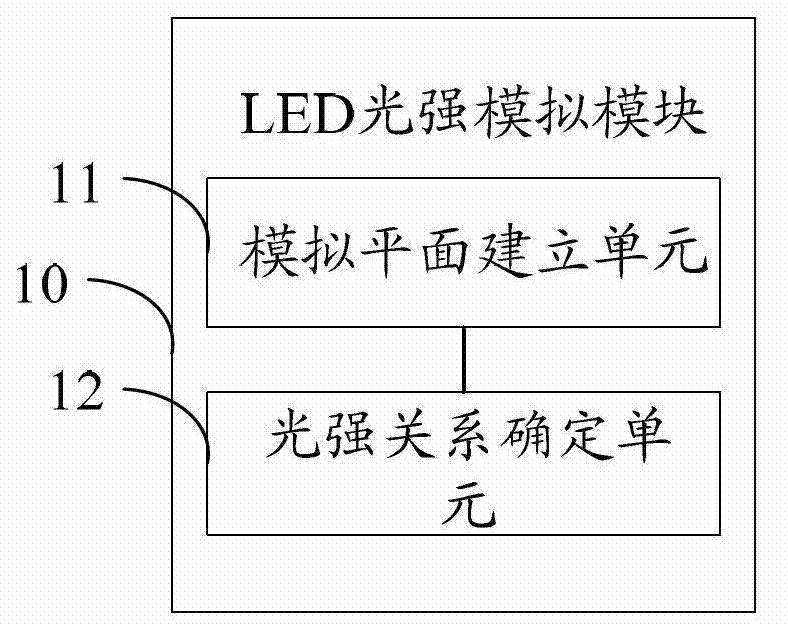

[0070] LED light intensity simulation module 10, for simulating LED light intensity distribution curve;

[0071] The diffusion plate illuminance acquisition module 20 is configured to acquire the illuminance of the diffusion plate according to the LED light intensity distribution curve;

[0072] Density distribution function generation module 30, for generating the density distribution function of dots according to the illuminance distribution of the diffusion plate and the transmittance of the diffusion plate;

[0073] The dot distribution generating module 40 is used to generate the regional distribution of dots by using a macro program VBA development tool.

[0074] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com