Method for arranging jacking pipe of rectangular open caisson

A caisson and pipe jacking technology, applied in pipeline laying and maintenance, mechanical equipment, cable installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0070] The test site is a pipe jacking project, the depth of the working well is 18.9m, the width is 18.2m, and the center of the pipe jacking is 12.9m from the surface.

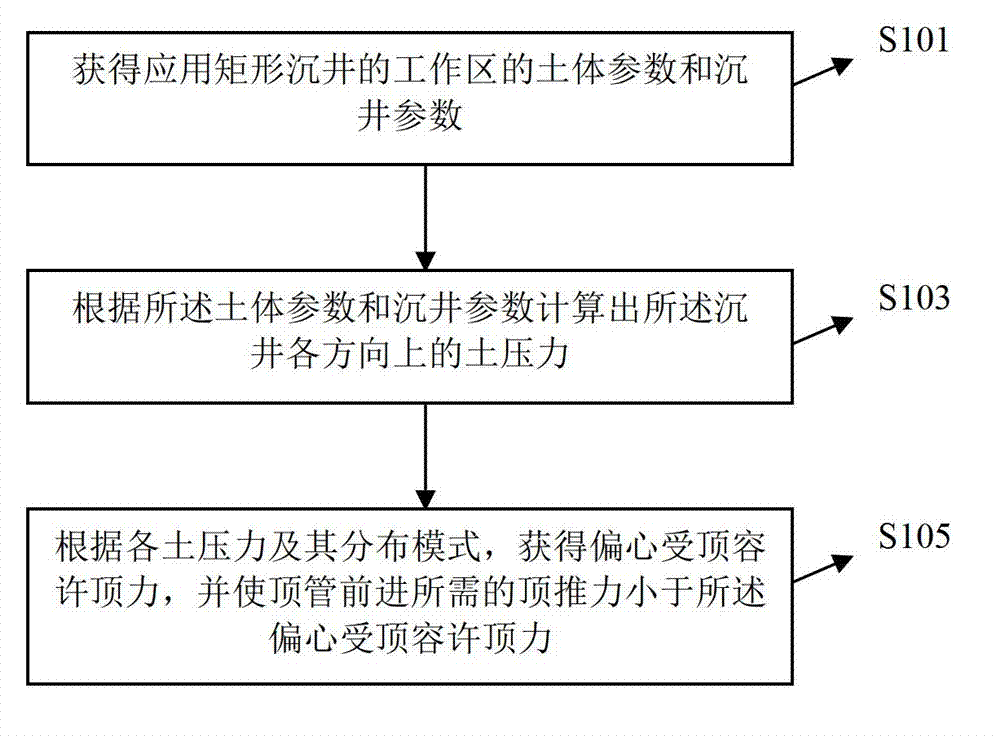

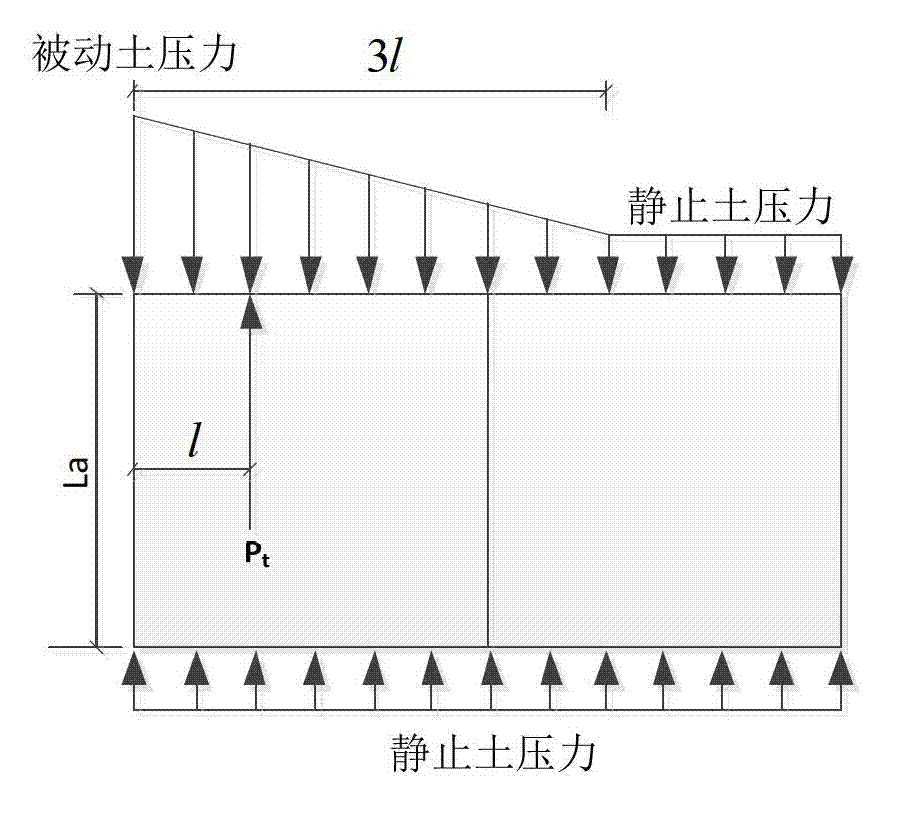

[0071] In order to optimize the calculation of the maximum jacking force, such as figure 1 force mode. The specific method and steps are as follows:

[0072] 1) Measure the average internal friction angle of the excavation through sampling test or in-situ test The average cohesion c=9kPa, the bulk density of soil γ=18kN / m3. According to the construction plan, it is determined that the buried depth from the bottom of the working well to the original ground is Hs=18.9m, the width of the working well is B=18.2, and the length L=11.2m.

[0073] Table 1 Soil layer material parameters

[0074]

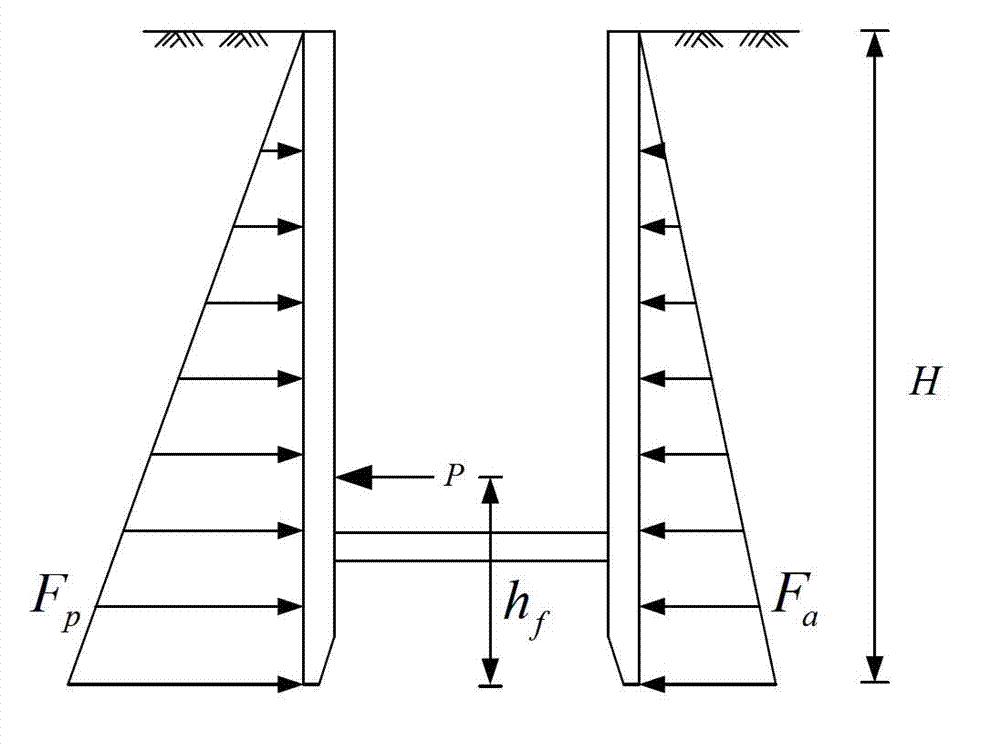

[0075] 2) Substituting the soil mass and working well parameters into each earth pressure formula, determining the earth pressure acting on the working well, taking the safety factor of 2.0, and calculating F max ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com