Mechanical sealing drive device with shaft seal

A technology of mechanical seals and transmissions, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of poor versatility of mechanical seals, relative slippage between shaft seals and shafts, and influence on transmission reliability. Achieve the effect of simple structure, convenient manufacture and good product versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

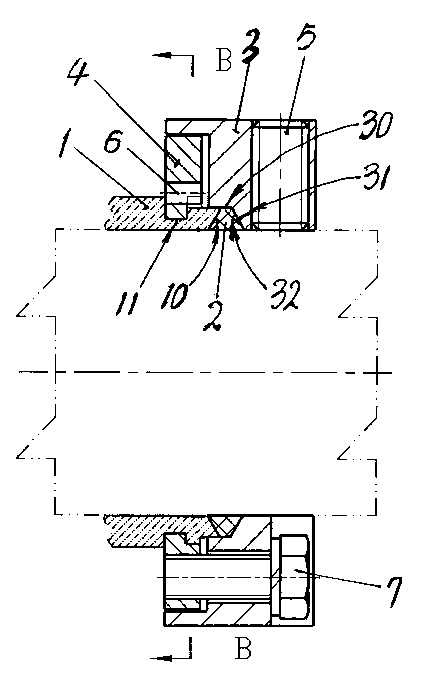

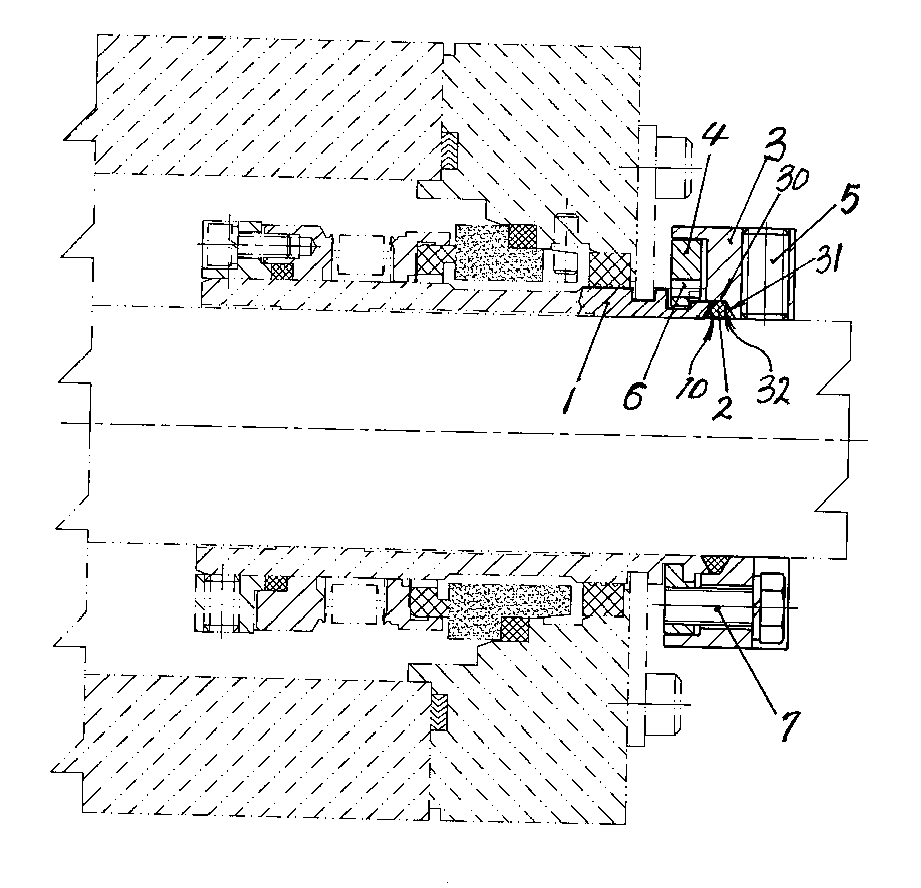

[0010] The mechanical seal transmission device with shaft seal of the present invention includes a moving ring shaft sleeve 1, a transmission ring 3, a shaft seal 2, a snap ring 4, a set screw 5, and a snap ring tension bolt 7. The transmission ring 3 is tightened by The screw 5 is fixedly connected with the shaft, the snap ring 4 cooperates with the card groove 11 opened on the moving ring sleeve 1 and is connected with the transmission ring 3 through the tightening bolt 7, and a shaft seal is set between the front end of the moving ring sleeve 1 and the transmission ring 3 2. It is characterized in that a trapezoidal notch groove 32 formed by an axial plane 30 and a radial slope 31 is opened on the inner ring surface of the transmission ring 3, and the outer end of the moving ring sleeve 1 with the inner tapered surface 10 is in contact with the The trapezoidal notch 32 of the transmission ring 3 cooperates, and the trapezoidal notch 32 of the transmission ring 3 cooperates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com