Crankless open type exhaust single-stroke piston type engine

A piston engine, open technology, applied in the direction of internal combustion piston engine, engine components, combustion engine, etc., can solve the problem of no leap forward, achieve the effect of weight reduction, increase of output power, and increase of output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

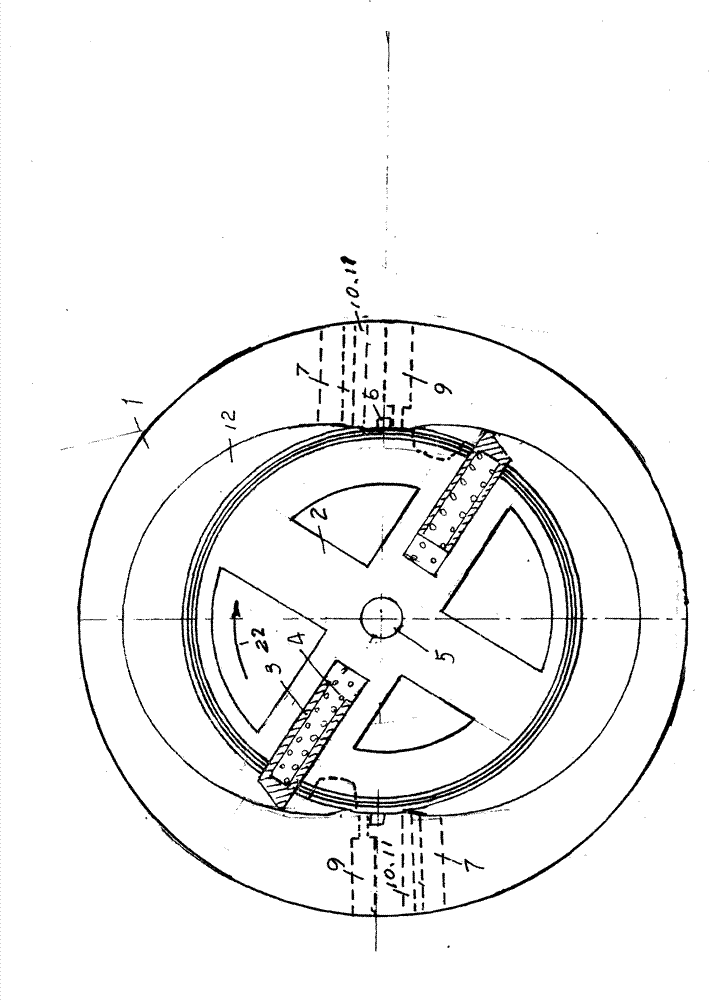

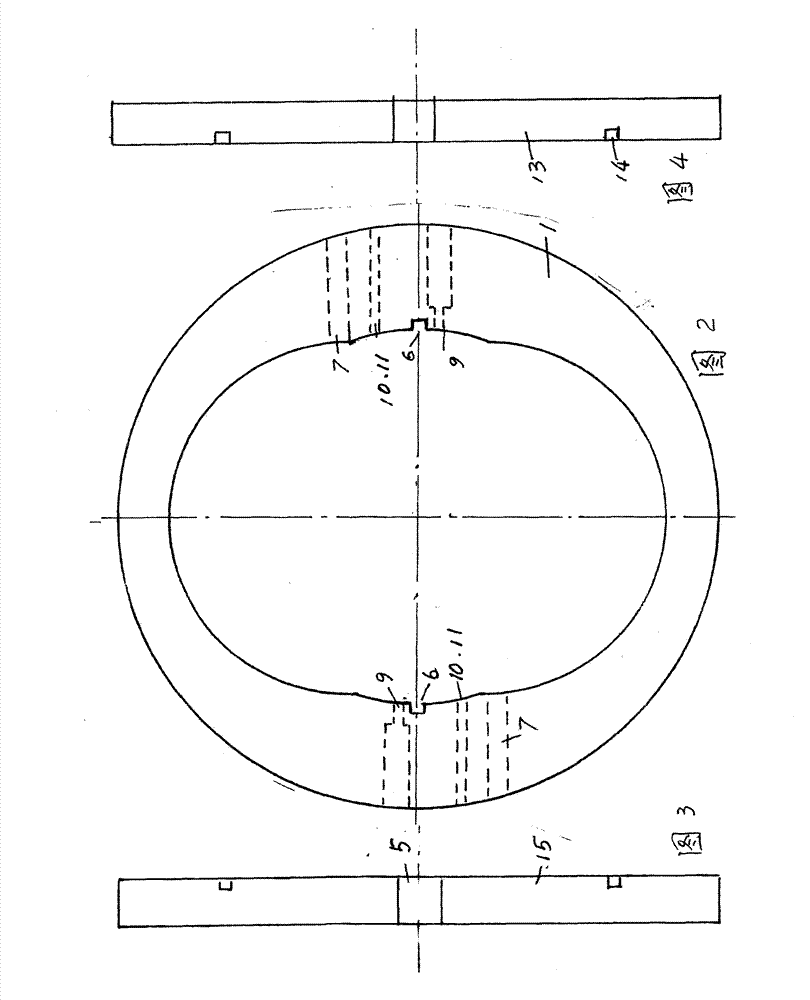

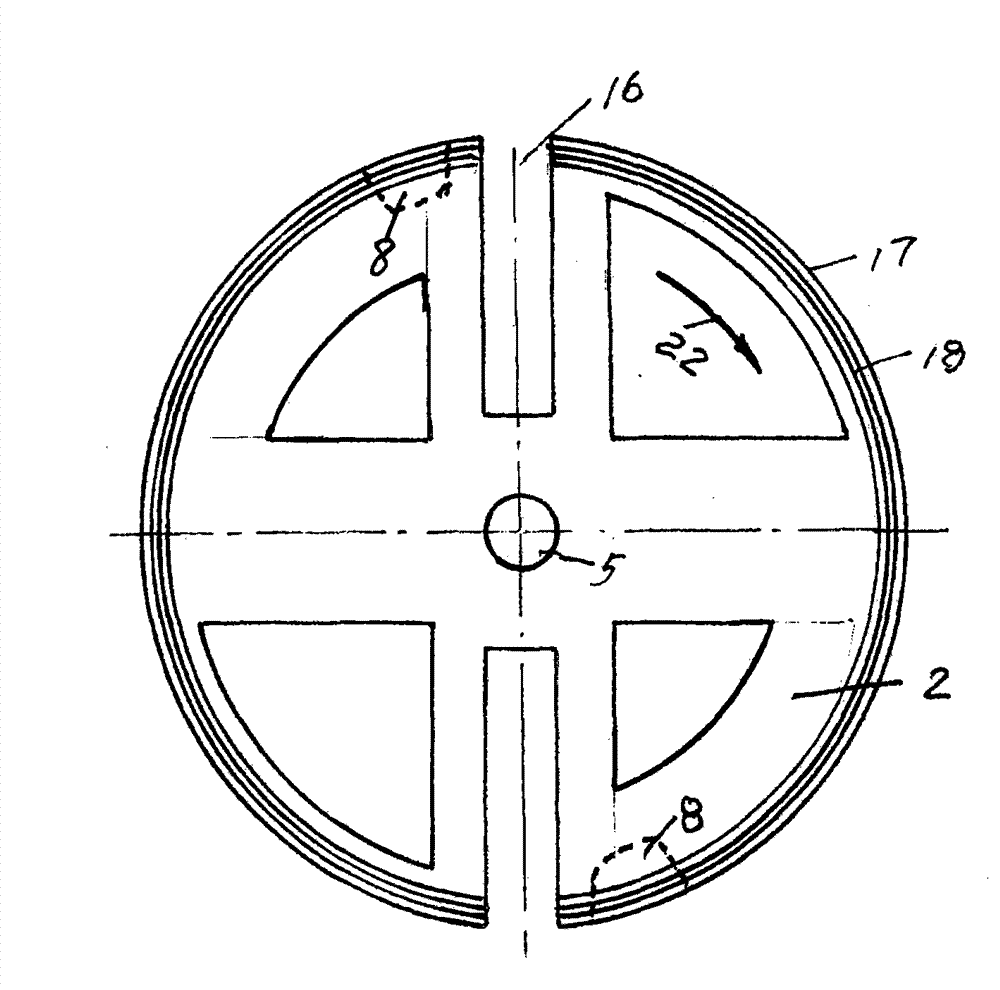

[0033] The concrete implementation of the present invention is not difficult. by figure 1 As an example, assume the engine is running along figure 1 The direction of the middle arrow runs normally, and the two pistons 3 rotate clockwise under the impetus of the high-temperature and high-pressure gas ejected from the combustion chamber 8 in the figure. At the same time, the piston moves forward to discharge the remaining waste gas from the previous cycle. Simultaneously, the piston overcomes the pressure of the compression spring 4 and moves downward along the radial direction under the effect of the descending curve of the cylinder body. Until the work is completed and enters the isolation and sealing area between the two cylinders, it is ready to do work next time. At this moment, after the piston running direction, the exhaust gas that finished the task of doing work is discharged voluntarily from the vent hole 7 of opening. The spokes continue to move and the piston 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com