Method for fermentation production of epsilon-polylysine by corn soaking water

A technology of corn soaking water and polylysine, applied in the field of fermentation engineering, can solve the problems of low utilization rate of corn soaking water, achieve the effects of protecting the environment, increasing yield and sugar-acid conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

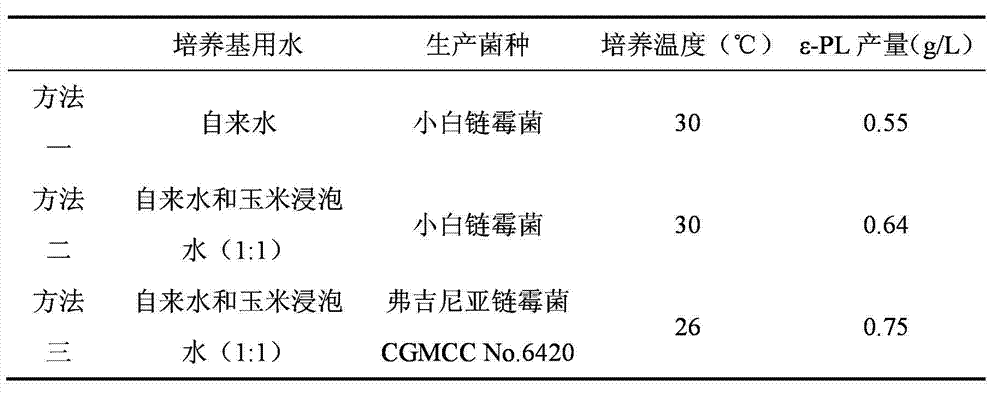

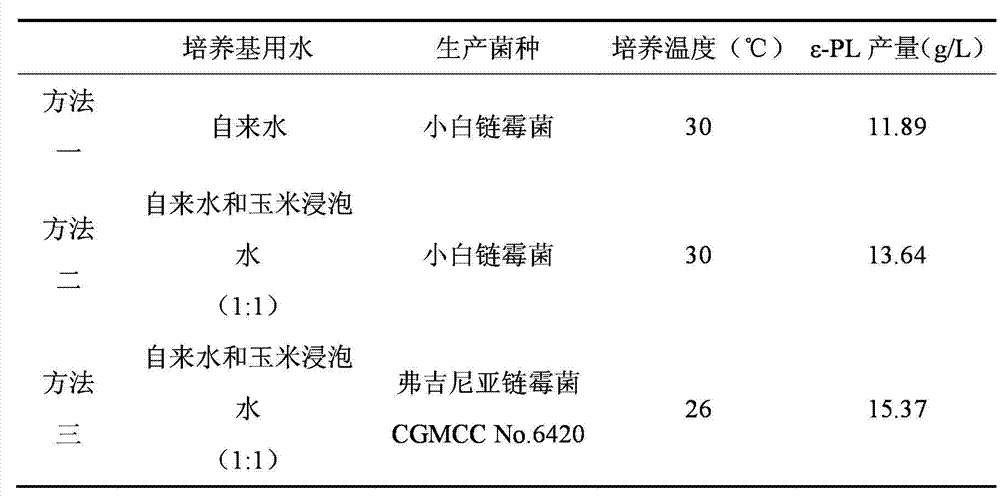

Method used

Image

Examples

Embodiment 1

[0018] (1) Precipitation: Let the fresh corn soaking water stand for 24 hours or filter to remove solids;

[0019] (2) Ingredients: Add the components of the medium into the corn soaking water treated in (1), glucose 40 g / L, yeast extract 3 g / L, KH 2 PO 4 1.5 g / L, K 2 HPO 4 1 g / L, (NH 4 ) 2 SO 4 8 g / L, the volume ratio of tap water and corn soaking water is 1:1, as feed solution, adjust pH to 3.9-4.1; as culture solution, adjust pH to 6.8-7.2;

[0020] (3) Sterilization: maintain the prepared culture at 121°C for 15 minutes, then lower it to 26°C;

[0021] (4) Inoculation: Inoculate according to the inoculum amount of 10% (v / v). The Streptomyces virginiae used has been preserved by the General Microbiology Center of China Committee for the Collection of Microbial Cultures. The preservation number is CGMCC No.6420, and the preservation date is As of August 13, 2012, the address of the preservation unit: No. 3, Yard No. 1, Beichen West Road, Chaoyang District, Beijing;...

Embodiment 2

[0024] (1) Precipitation: Let the fresh corn soaking water stand for 24 hours or filter to remove solids;

[0025] (2) Ingredients: Add the components of the medium into the corn soaking water treated in (1), glucose 45 g / L, yeast extract 4.5 g / L, KH 2 PO 4 1.5 g / L, K 2 HPO 4 1 g / L, (NH 4 ) 2 SO 4 10 g / L, the volume ratio of tap water and corn soaking water is 1:1, as feed solution, adjust pH to 3.9-4.1; as culture solution, adjust pH to 6.8-7.2;

[0026] (3) Sterilization: maintain the prepared culture at 123°C for 18 minutes, and then lower it to 29°C;

[0027] (4) Inoculation: Inoculate according to the inoculum amount of 10% (v / v). The Streptomyces virginiae used has been preserved by the General Microbiology Center of China Committee for the Collection of Microbial Cultures. The preservation number is CGMCC No.6420, and the preservation date is As of August 13, 2012, the address of the preservation unit: No. 3, Yard No. 1, Beichen West Road, Chaoyang District, B...

Embodiment 3

[0030] (1) Precipitation: Let fresh corn soaking water stand for 24 hours or filter to remove solids;

[0031] (2) Ingredients: Add the components of the medium into the corn soaking water treated in (1), glucose 50 g / L, yeast extract 6 g / L, KH 2 PO 4 1.5 g / L, K 2 HPO 4 1 g / L, (NH 4 ) 2 SO 4 12 g / L, the volume ratio of tap water and corn soaking water is 1:1, as feeding solution, adjust pH to 3.9-4.1; as culture solution, adjust pH to 6.8-7.2;

[0032] (3) Sterilization: maintain the prepared culture at 125°C for 20 minutes, then lower it to 32°C;

[0033](4) Inoculation: Inoculate according to the inoculum amount of 10% (v / v). The Streptomyces virginiae used has been preserved by the General Microbiology Center of China Committee for the Collection of Microbial Cultures. The preservation number is CGMCC No.6420, and the preservation date is As of August 13, 2012, the address of the preservation unit: No. 3, Yard No. 1, Beichen West Road, Chaoyang District, Beijing; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com