Energy absorbing device

An energy-absorbing device and energy-absorbing tube technology, which is applied in the field of safety, can solve problems such as large fluctuations in impact resistance, deformation of longitudinal beams and car bodies, and collapse in ideal conditions, and achieve stable energy absorption, stable energy absorption, and stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

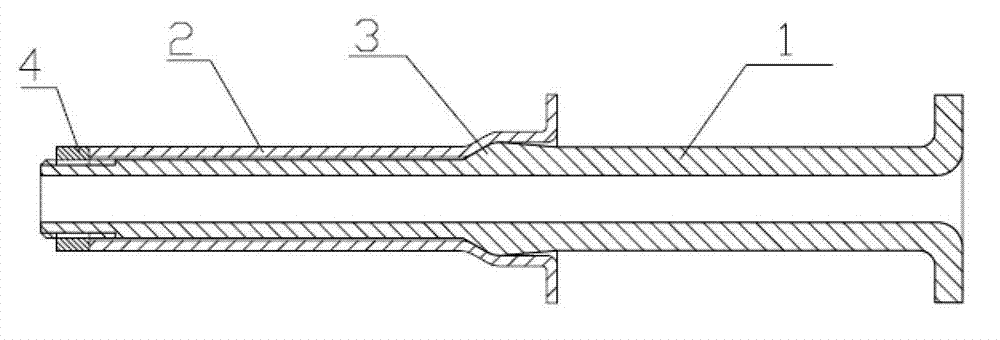

[0022] Embodiment 1: as figure 1 As shown, take an energy-absorbing tube 2 with uniform wall thickness and good plasticity, the cross-sectional shape of the energy-absorbing tube 2 can be circular or polygonal, and the inner wall surface of the energy-absorbing tube 2 is coated with lubricant, so The above-mentioned lubricant can be selected from a dry film lubricant, etc., to ensure that the energy-absorbing tube 2 does not stick to the expansion rod 1 when it expands, and the friction force is stable, thereby ensuring stable expansion resistance.

[0023] One end of the energy-absorbing tube 2 is punched out of a horn-shaped opening with a groove, and the flange is flanged or welded, and a longer expansion rod 1 is inserted from the end of the horn-shaped opening, and a part of the expansion rod 1 is inserted into the suction Inside the energy tube 2, the other part is exposed outside the energy-absorbing tube 2. A convex portion 3 is provided on the outer wall of the expans...

Embodiment 2

[0025] Embodiment 2: Compared with Embodiment 1, the difference is that the energy-absorbing tube 2 is obtained by welding one end of a thick seamless steel pipe and one end of a thin seamless steel pipe, and the expansion rod 1 with the convex part 3 is obtained from One end of the thick seamless steel pipe is inserted, and the outer diameter of the convex part 3 of the expanding rod 1 is smaller than the inner diameter of the thick seamless steel pipe and larger than the inner diameter of the thin seamless steel pipe, so the expanding rod 1 passes through the convex part 3 after being inserted into the thick seamless steel pipe Clamped on one end of the thin seamless steel pipe, the second embodiment of the device is obtained.

Embodiment 3

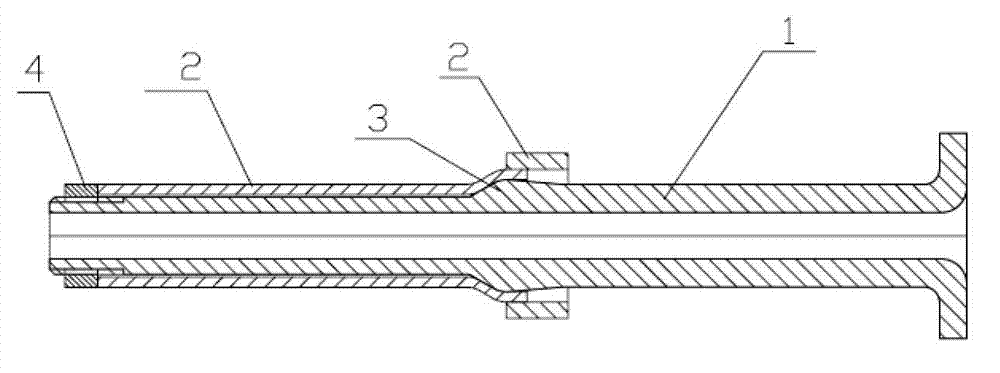

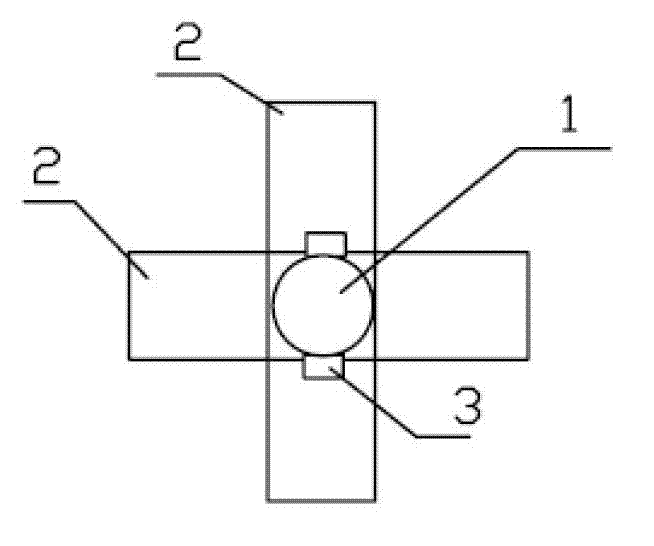

[0026] Embodiment 3: Compared with Embodiment 1, the difference is that, as figure 2 As shown, the energy-absorbing pipe 2 is two identical steel pipes with a rectangular cross-section, one end of one steel pipe is welded to one end of the other steel pipe, and the two steel pipes are vertically arranged, that is, form a "cross" from a top view shape. The expansion rod 1 is inserted from one end of a steel pipe at the cross-shaped intersection area, and the expansion rod 1 has a radially outwardly extending convex portion 3, and another steel pipe is clamped by the convex portion 3 to obtain the present invention. The third implementation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com