High-speed permanent magnetic wind driven generator rotor sheet

A wind turbine, rotor punching technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of complex manufacturing and assembly processes, reducing the reliability of rotor structure, and difficulty in rotor ventilation and heat dissipation. , to achieve the effect of easy processing and manufacturing, improving anti-demagnetization ability and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

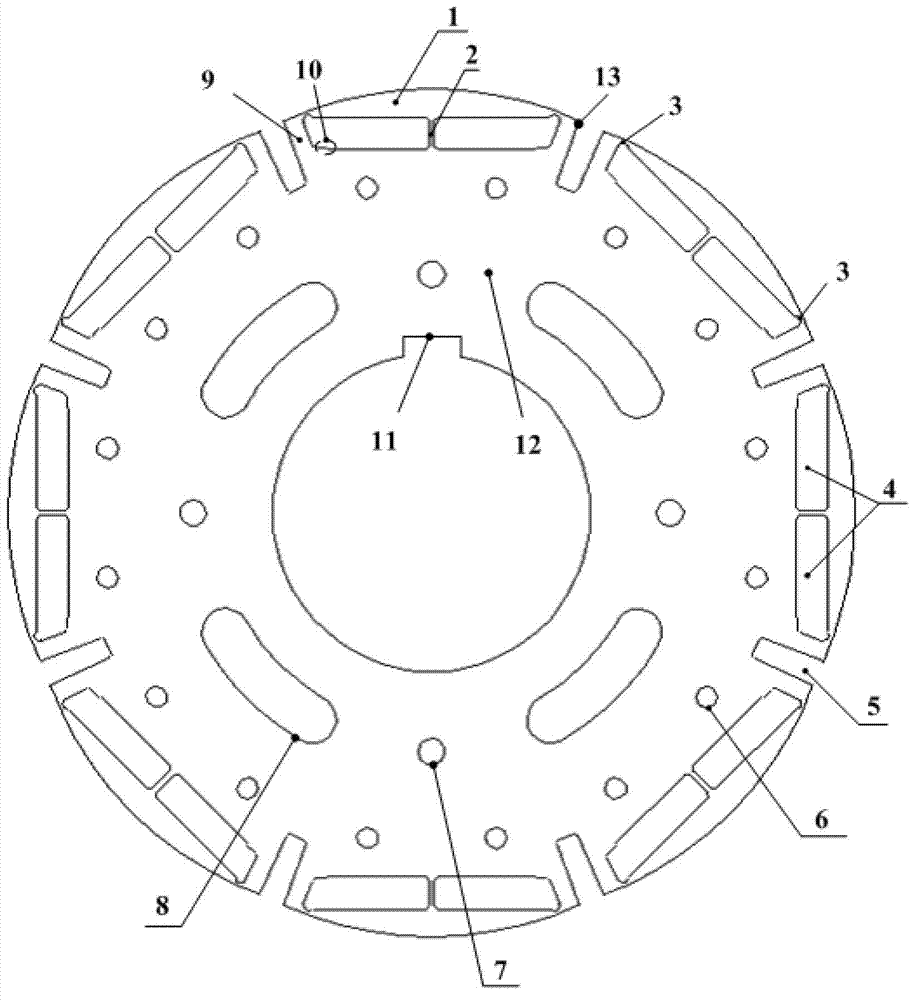

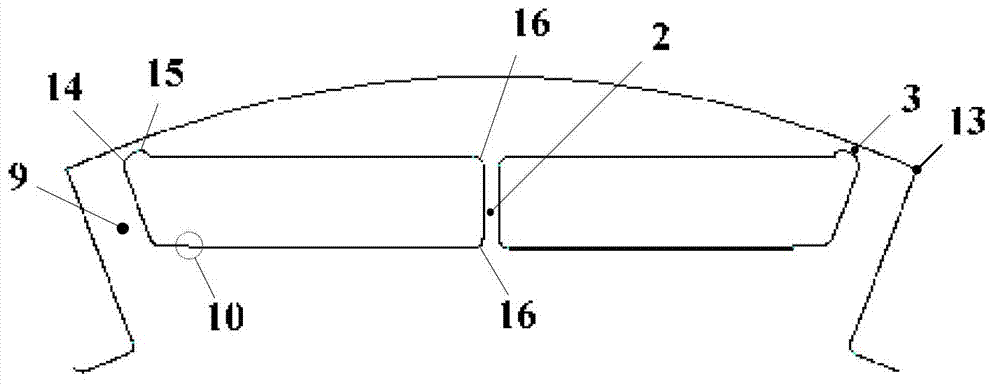

[0020] Such as figure 1 As shown, the present invention is a high-speed permanent-magnet wind-driven generator rotor punch applied to a high-speed permanent-magnet wind-driven generator, and the example is an 8-pole structure. The rotor punching piece is in the form of a full circle punching piece. Each rotor magnetic pole 13 has two symmetrical permanent magnet slots 4, which are separated by the middle magnetic bridge 2. The outer circle of the rotor magnetic pole 13 is an eccentric arc; The magnetization directions of the permanent magnets installed in the slot 4 are the same, and the magnetization directions of adjacent magnetic poles are opposite. Each permanent magnet slot is provided with an installation positioning step 10 toward the bottom of the slot inside the rotor punching plate; between two adjacent rotor poles, there is a The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com