Linear measurement arrangement method for stainless steel vehicle roof cap-shaped curved beams

A stainless steel, hat-shaped technology, which is applied in the direction of mechanical clearance measurement, etc., can solve the problem of the arrangement and measurement of the interval size of hat-shaped curved beams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

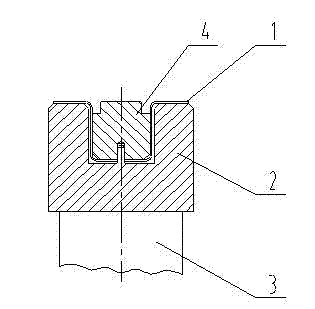

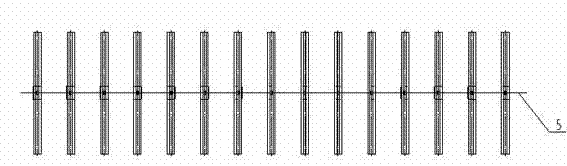

[0008] refer to figure 1 , figure 2 , 1 is a stainless steel roof hat-shaped curved beam, 2 is a groove body with a center positioning pin, 3 is the lower leg of the groove body, and 4 is a measuring block. There is a pin hole in the center of the bottom surface, and a pin hole coaxial with the pin hole on the top The center hole of the heart is as the center marking point, and 5 is the center backguy.

[0009] The stainless steel roof hat-shaped curved beam 1 is an arc-shaped skeleton beam that constitutes a new subway car, and several groups of stainless steel roof hat-shaped curved beams 1 are required to be combined into a car. The upper part of the groove body 2 with the central positioning pin is in the shape of a groove, and the bottom of the groove has a central positioning pin, which can be matched with the round hole in the center of the stainless steel roof hat-shaped curved beam 1 to determine the stainless steel roof hat-shaped curved beam 1 for center position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com