Third-generation heavy fighter novel gas inlet channel lip

A technology for air intakes and fighter jets, which is applied in the combustion of air intakes of power plants, air intakes of turbines/propulsion devices, weight reduction, etc., and can solve problems affecting the combat effectiveness of fighter jets, the inability to extend the sliding distance, and small engine thrust, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

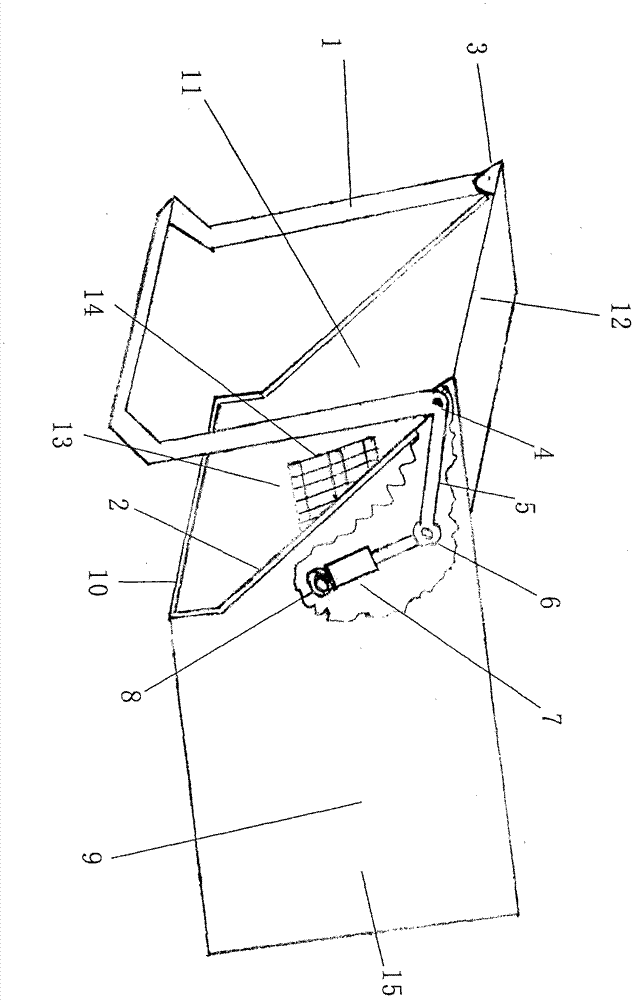

[0005] The present invention divides the fixed inlet lip of the existing air inlet 15 into a movable lip 1 and a fixed lip 2 with a larger radius relative to the lip, and at both ends of the front part of the boundary layer partition 12 The rectifier box 3 is installed on the lower side, and the movable lip is installed on the front upper part of the air inlet wall on both sides through the hinge shaft 4, and the movable lip is installed on the internal installation joint 8 of the inner wall 9 of the air inlet. The moving barrel 7 is connected together by the connecting bolt 6 and the movable lip retractable pull rod 5 at the inner rear portion of the movable lip, the same as the existing third-generation heavy-duty fighter, and still leaves a hole on the outer side wall 11 of the air inlet. Auxiliary intake valve 14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com