crankshaft cam valve train

A gas distribution mechanism and cam technology, which is applied to mechanical equipment, engine components, machines/engines, etc., can solve the problems of high manufacturing cost and complex gas distribution mechanism, and achieve low manufacturing cost, precise gas distribution and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

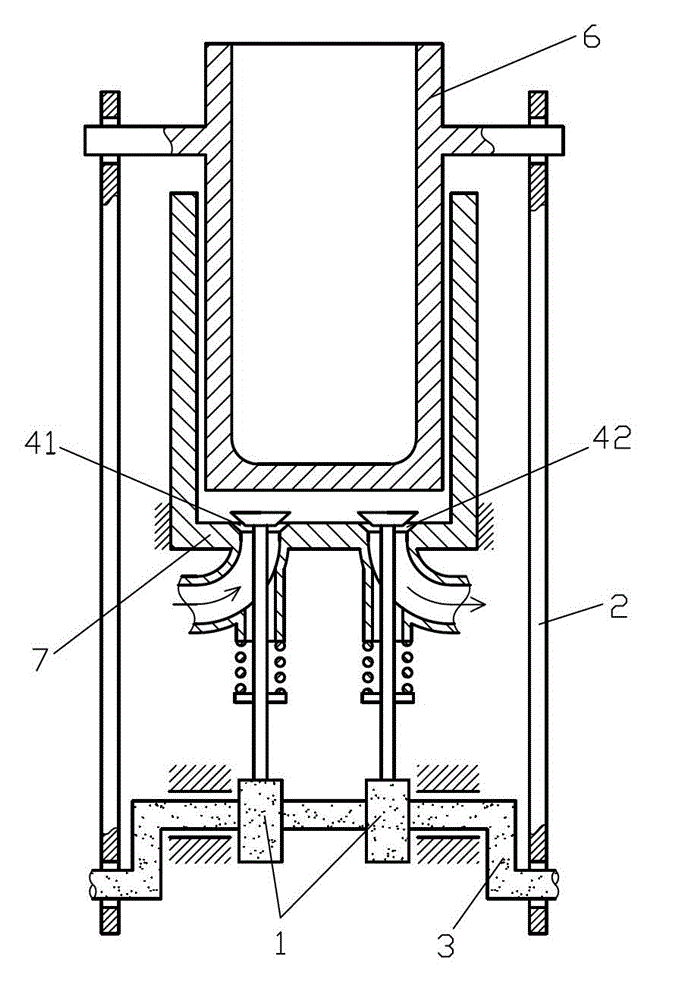

[0046] like figure 1 The shown crankshaft cam gas distribution mechanism includes a gas distribution displacement member, a gas distribution seat port and a cam 1, the gas distribution seat port is arranged on the cylinder mechanism fixing part of the cylinder piston mechanism, and the gas distribution displacement member is connected to the The air distribution seat port is matched, the cylinder mechanism slider of the cylinder piston mechanism is rotationally connected with the connecting rod journal of the crankshaft 3 through the connecting rod 2, the cam 1 is arranged on the main journal of the crankshaft 3 and controls the distribution The air displacement member distributes air to the cylinder-piston mechanism.

[0047]In this embodiment, the gas distribution displacement member is configured as a gas distribution valve, the piston of the cylinder-piston mechanism is configured as a sliding piston 6, the cylinder liner of the cylinder-piston mechanism is configured as ...

Embodiment 2

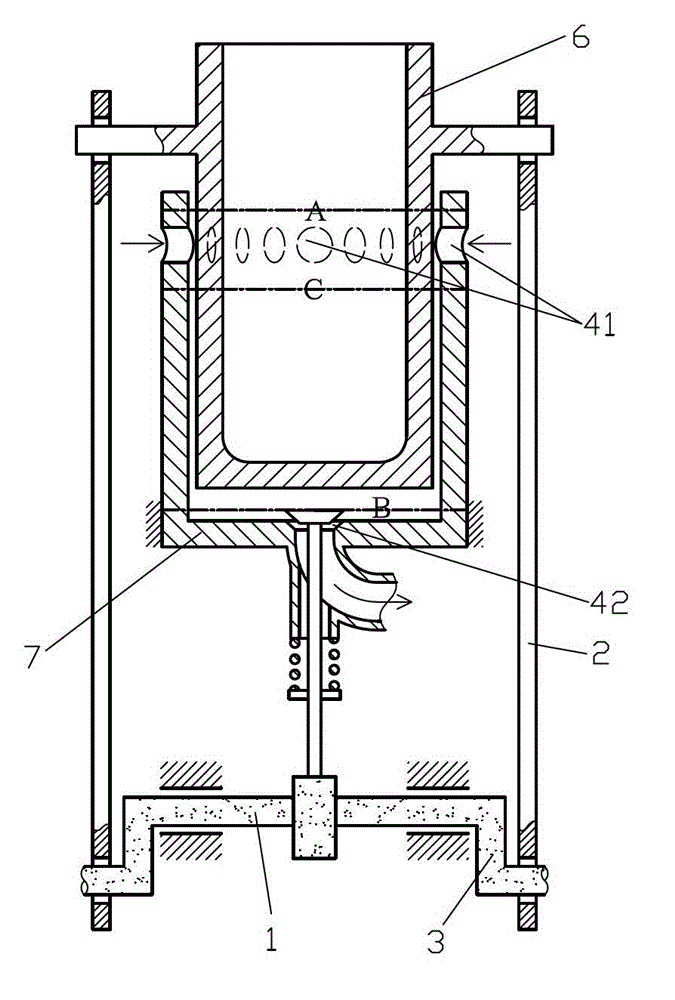

[0053] like figure 2 The difference between the shown crankshaft cam valve mechanism and Embodiment 1 is that the air inlet 41 is arranged on the side wall of the fixed cylinder liner 7 , specifically at the bottom dead center of the sliding piston 6 nearby location.

[0054] This embodiment can work according to the two-stroke engine working mode. When the sliding piston 6 is at the bottom dead center A, the air inlet 41 and the exhaust port 42 are in an open state, and the air inlet 41 is in an open state. A scavenging pump is connected, and the scavenging pump feeds compressed gas into the cylinder of the cylinder-piston mechanism to force the scavenging to discharge the residual exhaust gas in the cylinder. When the sliding piston 6 moves to the upper dead center, before closing the air inlet 41, The exhaust valve controlled by the cam 1 is closed first, and when the sliding piston 6 is close to the top dead center B, fuel injection ignition is performed, and the sliding...

Embodiment 3

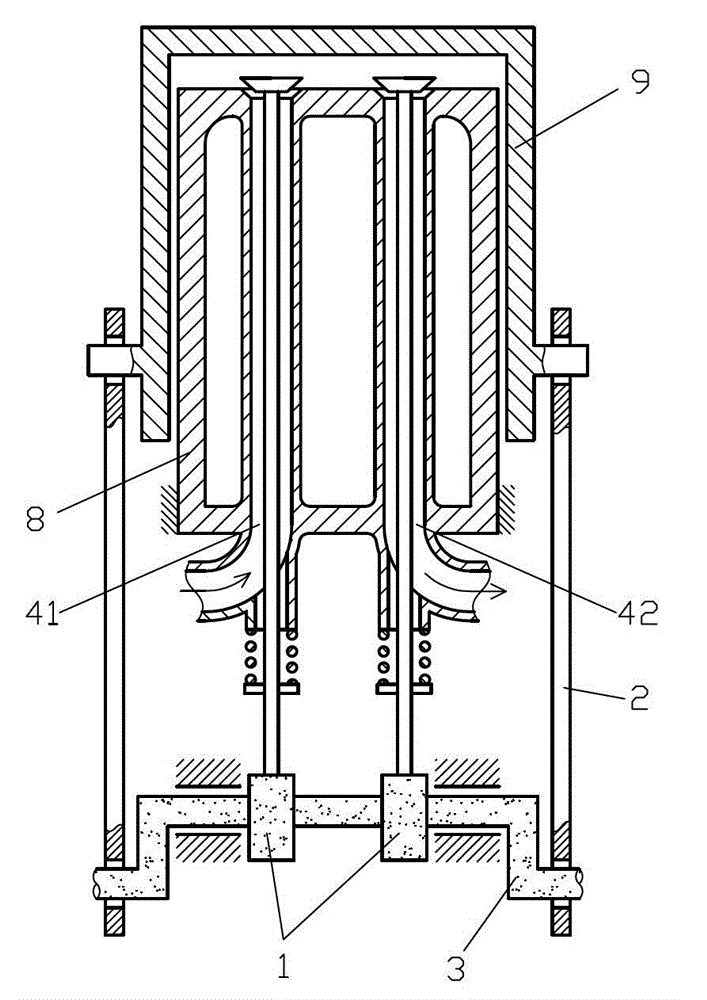

[0056] like image 3 The shown crankshaft cam valve mechanism differs from Embodiment 1 in that the piston of the cylinder-piston mechanism is set as a fixed piston 8, the cylinder liner of the cylinder-piston mechanism is set as a sliding cylinder liner 9, and the cylinder liner of the cylinder-piston mechanism is set as a sliding cylinder liner 9. The fixed part is set as the fixed piston 8, the sliding part of the cylinder mechanism is set as the sliding cylinder liner 9, and an air distribution seat is set on the fixed piston 8, and the air distribution seat includes an air inlet 41 and An exhaust port 42, an intake valve is set at the intake port 41, an exhaust valve is set at the exhaust port 42, and the intake valve and the exhaust valve are respectively controlled by two cams 1 control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com