Cold storage board

A cold storage board and panel technology, which is applied in the direction of building components, buildings, building structures, etc., can solve the problems that the panel steel plate is thin and can not be installed on one side, the construction operation is inconvenient, and the airtightness cannot be guaranteed, etc., to achieve good The effect of airtightness, practical function and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

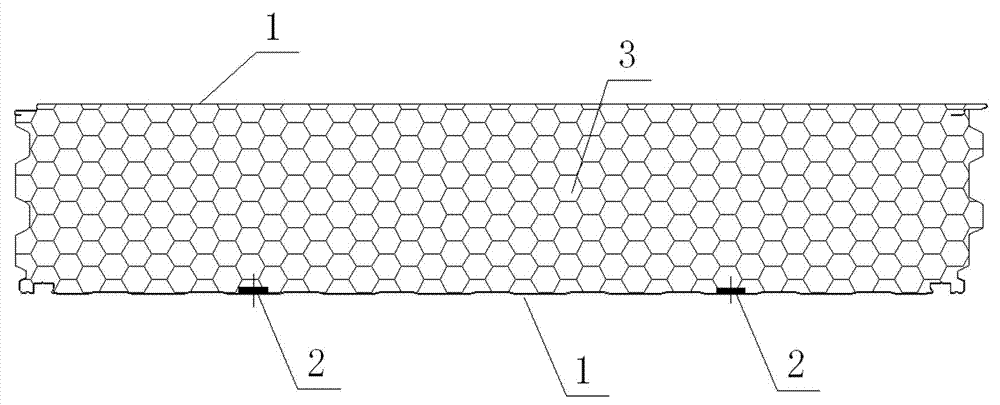

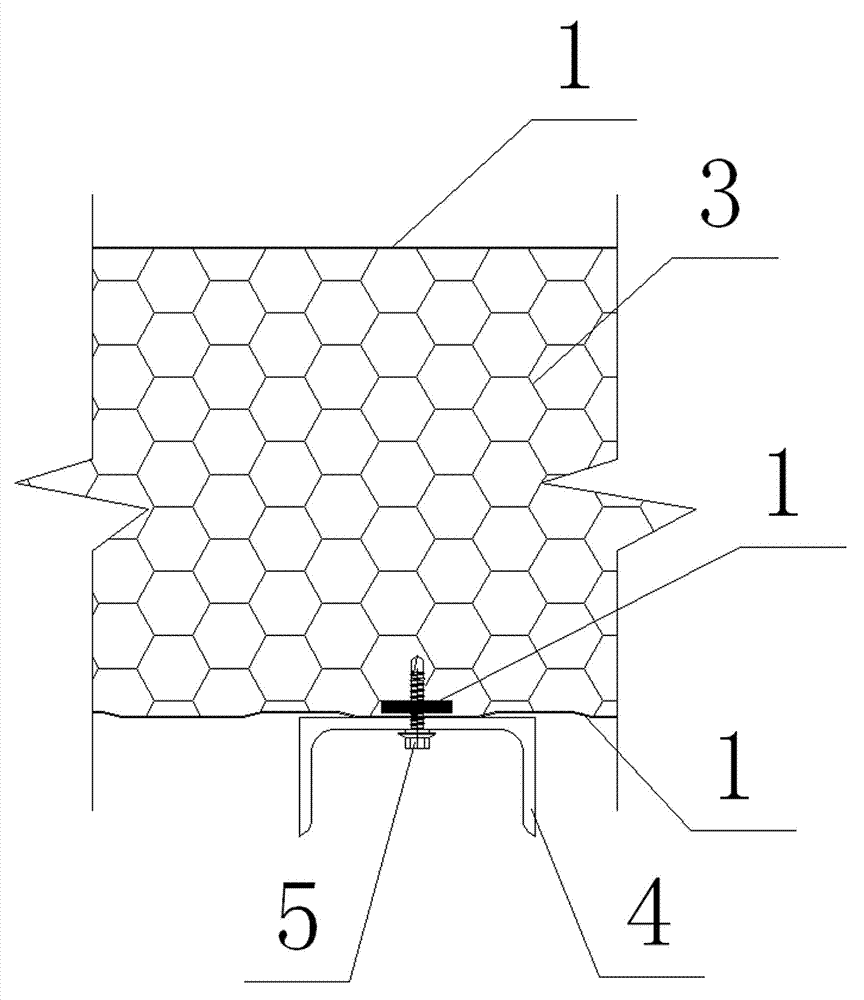

[0010] Example: such as figure 1 , 2 As shown, a cold storage panel includes panels 1 on both sides and polyurethane foam 3 between them. Two long reinforcing ribs 2 are arranged at the installation position of one side panel of the cold storage panel, and the installation purlin 4 is automatically drilled The tapping screw 5 is fixed on the reinforcing rib 2. The reinforcing rib 2 is a plate-like steel bar. Grooves are provided on the panels 1 corresponding to both sides of the long reinforcing rib 2 , and protrusions are relatively formed on the panel 1 corresponding to the reinforcing ribs 2 , and the width of the protrusions is smaller than the width of the purlin 4 .

[0011] The installation of the present invention adopts a single-sided installation method. At the 2 reinforcement ribs added to the cold storage panel, the single-sided installation of the cold storage panel is fixed on the purlin 4 at the corresponding position with a drill tail self-tapping screw 5 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com