Drainage system capable of lowering drainage noise of washing machine and control method thereof

A drainage system and washing machine technology, which is applied to the control device of the washing machine, other washing machines, washing devices, etc., can solve the problems of large noise of the drainage pump, increased energy consumption, and ineffective effect, and achieve high drainage efficiency, noise reduction, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

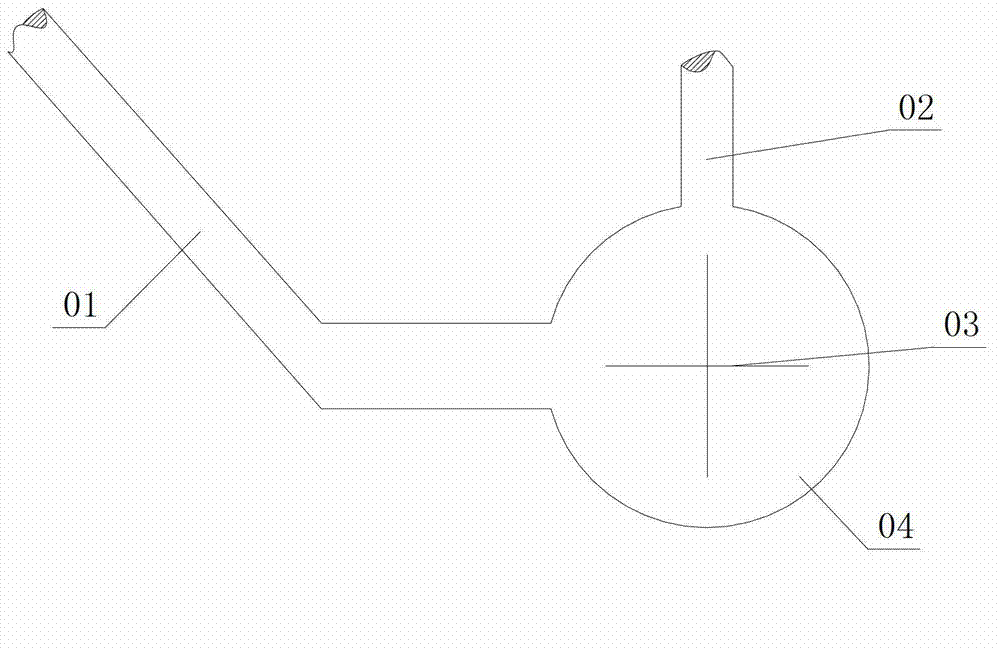

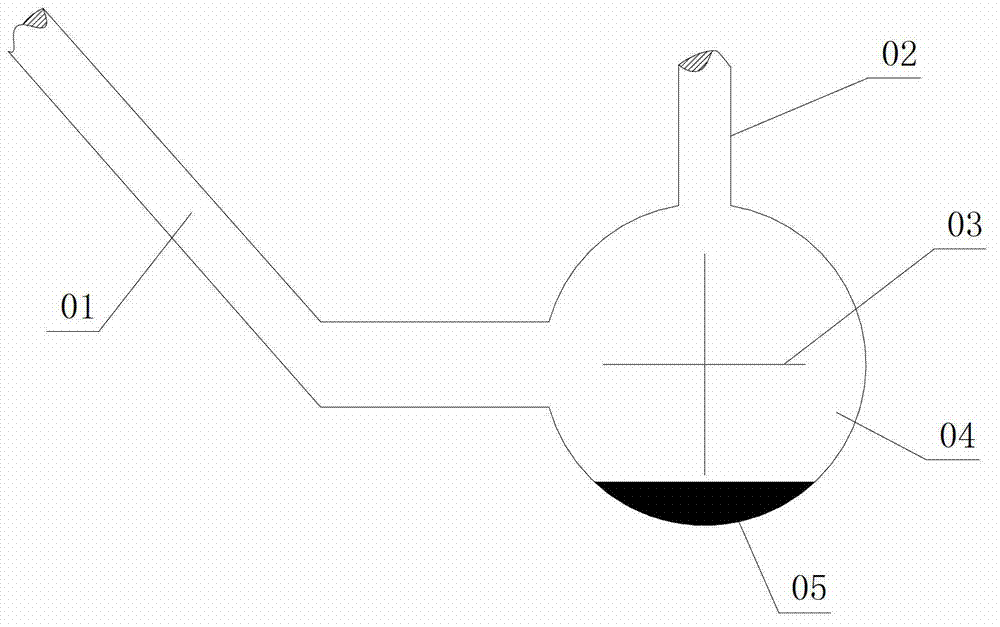

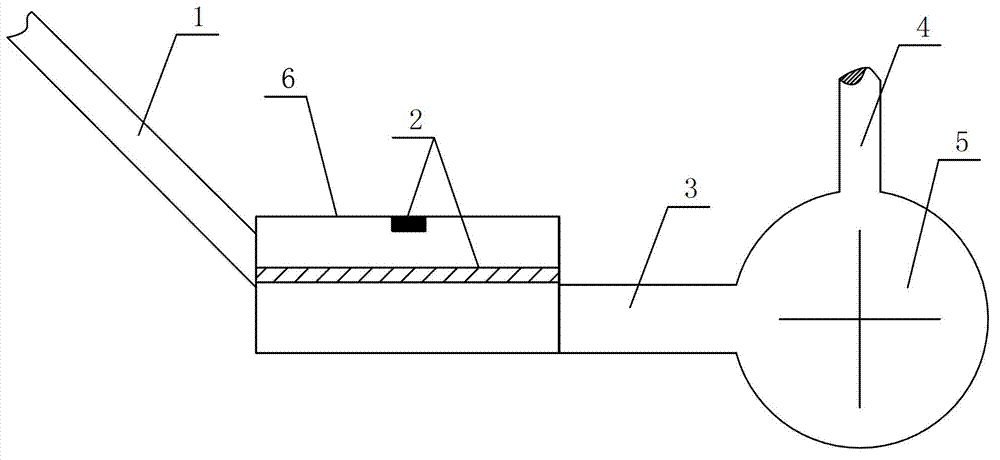

[0030] Such as Figure 3-4 As shown, the drainage system for reducing the drainage noise of the washing machine described in this embodiment includes a drainage pump 5, and the drainage pump 5 includes a drainage pump inlet pipe 3 and a drainage pump outlet pipe 4, between the drainage pump inlet pipe 3 and the drainage pump outlet pipe 4. A fixed water tank 6 is arranged between the outer cylinders of the washing machine. A float switch 2 is arranged in the fixed water tank 6. The float switch 2 includes a float 21 which is movable inside the fixed water tank 6. The density of the float 21 is greater than the density of water, so that the float 21 can follow the The water quantity in the fixed water tank 6 changes and goes up and down, and a float switch button 22 connected with an external controller is arranged at the top of the fixed water tank 6 at the same time. In order to ensure the normal operation of the entire drainage system, the lowest surface of the inner cavity ...

Embodiment 2

[0038]The drainage system for reducing the drainage noise of the washing machine described in this embodiment includes a drainage pump. The drainage pump includes a drainage pump inlet pipe and a drainage pump outlet pipe. Water tank, the sensor is fixed in the fixed water tank, and the water level mark is set corresponding to the sensor in the fixed water tank. The position of the water level mark is consistent with the full water position of the drainage pump, and the sensor is connected to the external controller, and the controller directly controls the drainage pump. start and stop work. In this way, the sensor can directly transmit the water level to the external controller, and the controller controls the real-time start and stop of the drainage pump to ensure that the water in the drainage pump is always kept full during the dehydration process of the washing machine, further avoiding the vibration of the washing machine during high-speed dehydration The superposition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com