Residual oil hydrotreating-catalytic cracking-solvent refining combined process

A technology of residual oil hydrogenation and solvent refining, which is applied in the fields of hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., can solve the problems of large amount of coke, low yield of light oil, increased load of regenerator, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

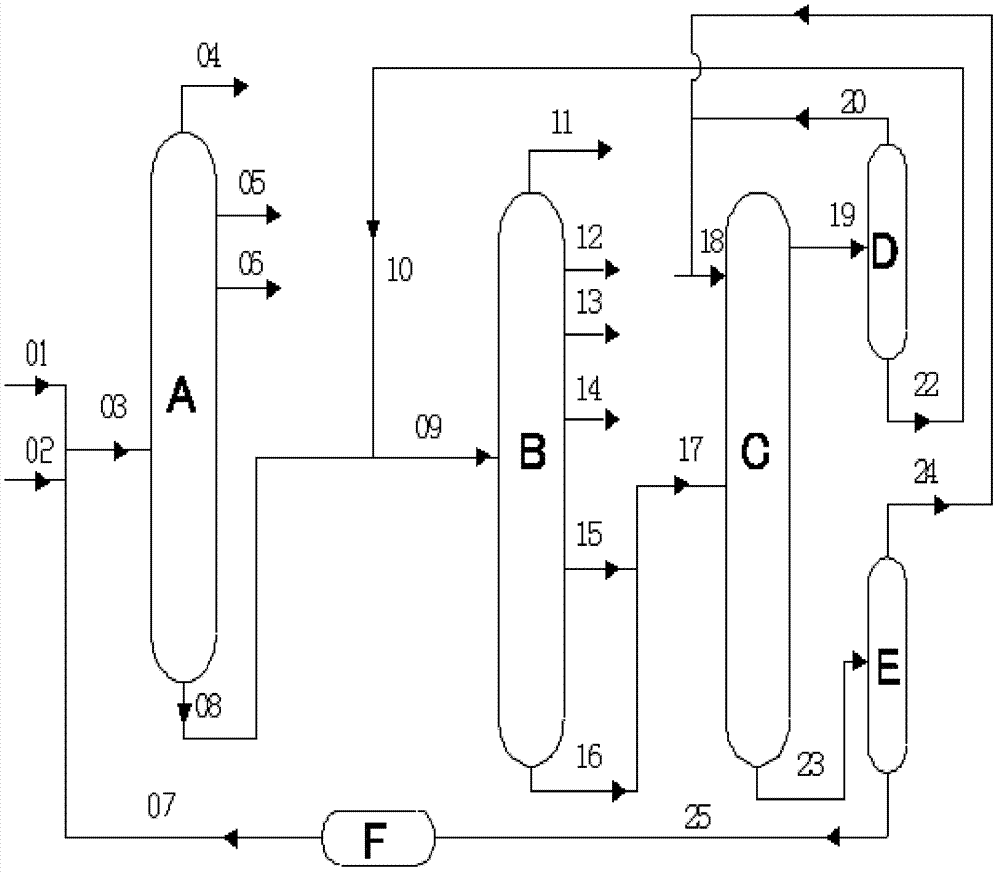

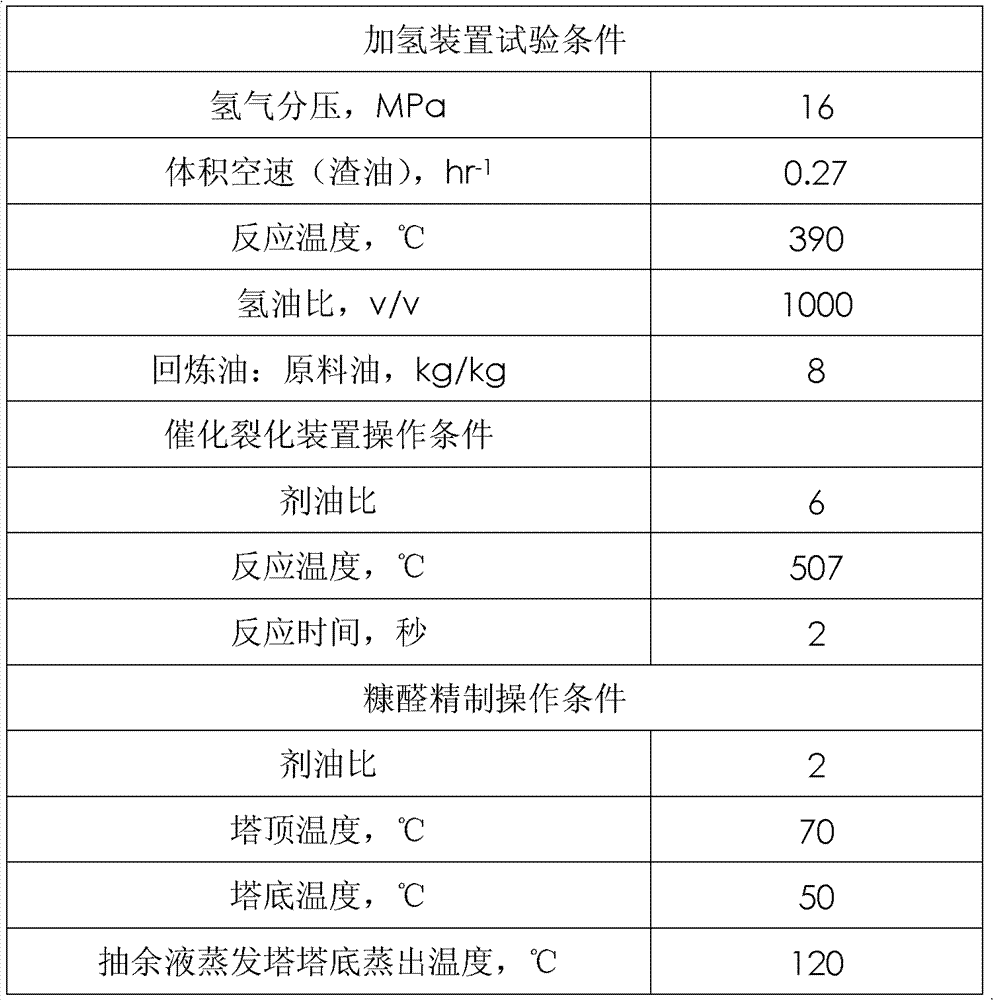

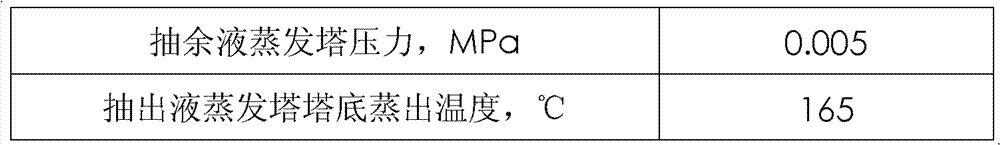

[0044] The residual oil is introduced into the residual oil hydrotreating unit for hydrogenation treatment, and the hydrogenated products are separated to obtain gas, hydrogenated naphtha, hydrogenated diesel oil and hydrogenated residual oil; the hydrogenated residual oil is directly\or and optionally gas oil They enter the catalytic cracking unit together, and the products are separated into dry gas, catalytic gasoline, catalytic diesel, heavy cycle oil and oil slurry; the heavy cycle oil and oil slurry are solvent-refined, and the extracted oil is processed to remove solid impurities and enters the residue together with the residual oil Oil hydrotreating unit, raffinate oil and hydrogenated residual oil enter the catalytic cracking unit together for reaction.

[0045] It can be seen from Table 3 that compared with the comparative example, the yield of hydrogenated diesel oil increased by 0.51%, and after 2000 hours, the carbon deposit on the catalyst was significantly reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com