Slotting unit of anode carbon block

A technology of anode carbon block and unit, which is applied in the direction of stone processing tools, manufacturing tools, stone processing equipment, etc., can solve the problems of inability to work continuously, low work efficiency, etc., achieve efficient cutting of exhaust grooves, low production cost, and excellent structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

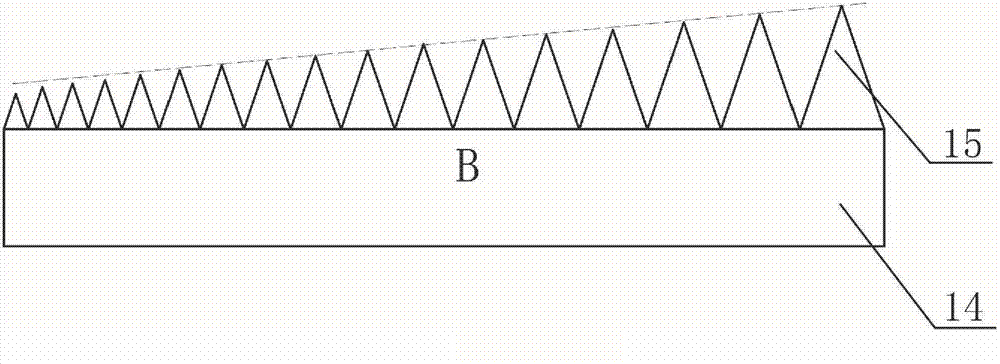

[0039] like Figure 1-4 As shown, the anode carbon block grooving unit includes three parts, the mobile trolley A, the grooving saw blade B and the cutting frame C,

[0040] The mobile trolley A includes a frame 1 and a motor. The frame 1 includes a support frame 1.1 at the bottom. The bottom of the frame 1 is provided with a track wheel 2. The upper part of the frame 1 is provided with an upper pressing device 3. The upper pressing device 3 includes an upper pressing device. Tightening plate 3.1, upper cam 3.2 and return spring A3.3, upper cam 3.2 is set on the top position of pressing plate 3.1, one end of connecting rod in returning spring A3.3 is connected with upper pressing plate 3.1, and the other end is connected with the vehicle The top of the frame 1 is connected; the side pressing device 4 includes an L-shaped side pressing plate 4.1, a side mechanical pull rod 4.2 and a return spring B4.3, and the end of the side mechanical pull rod 4.2 is connected with the side pre...

Embodiment 2

[0045] The difference from Embodiment 1 is that the rear part of the upper pressing plate 3.1 is also provided with a tailgate 3.4, the upper cam 3.2 is replaced by a hydraulic push rod, the side mechanical pull rod 4.2 is also replaced by a hydraulic push rod, and the saw blade mechanical push rod 16 is replaced Forming a hydraulic push rod, the angle between the straight line formed by the top of the sawtooth and the base of the saw blade is 3 degrees, and the other working principles are the same as in Embodiment 1.

Embodiment 3

[0047] The difference from Embodiment 1 is that the upper cam 3.2 is replaced by a mechanical push rod, and the side mechanical pull rod 4.2 is replaced by a cam. The straight line formed by the top of the sawtooth and the saw blade base form an included angle of 5 degrees. Other working principles are the same as in Embodiment 1. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com