A rare earth elements doping on yttrium oxide luminescent thin film containing conductive oxides and preparation methods thereof

A technology of conductive oxides and rare earth elements, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of difficult control of the phosphor coating process, reduce the luminous efficiency of the phosphors, and affect the service life of the phosphors, and improve the electrical conductivity. The performance is not high, the luminous performance is improved, and the cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

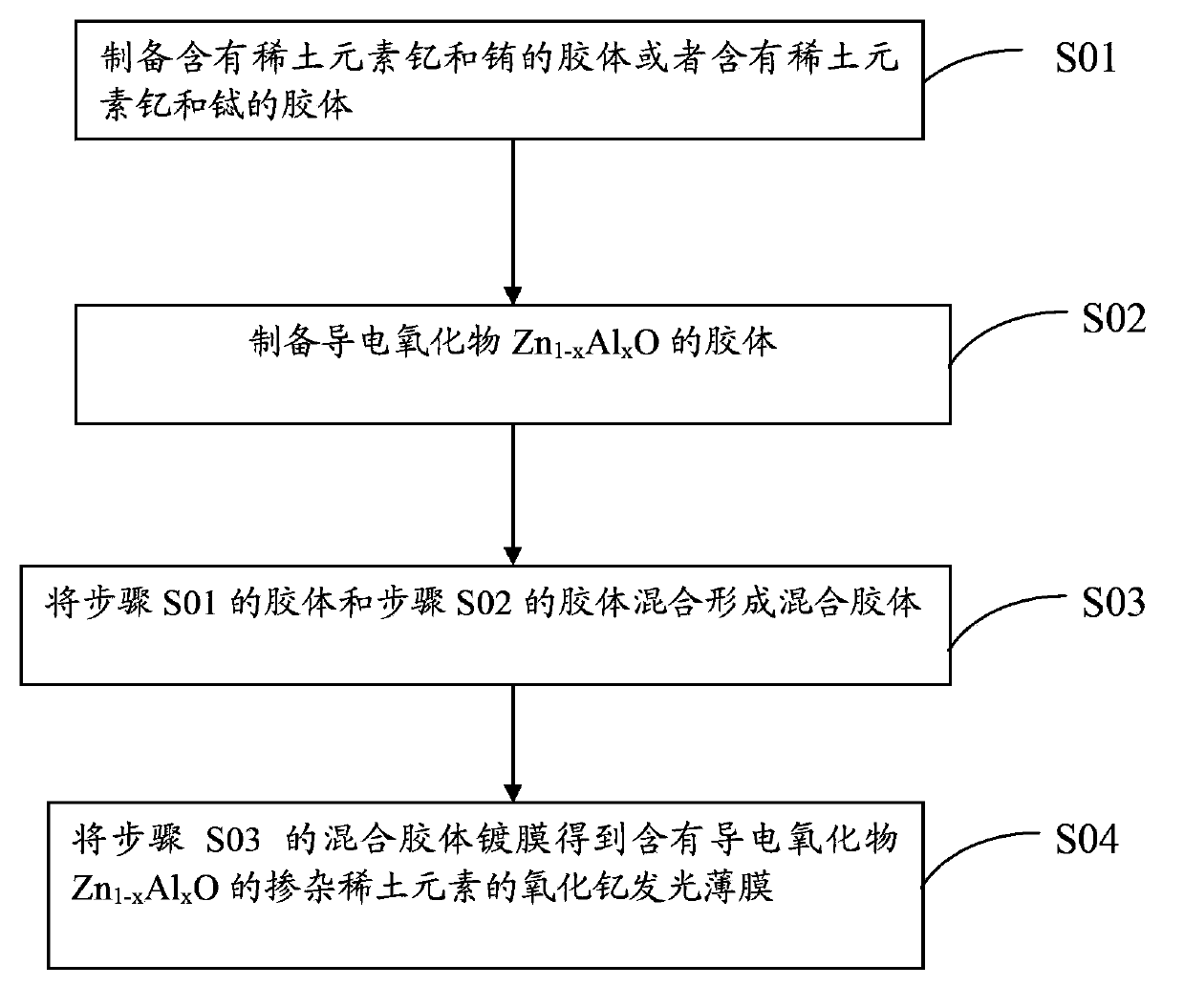

[0021] see figure 1 , figure 1 The flow chart of the preparation method of the yttrium oxide luminescent thin film containing conductive oxide doped with rare earth elements of the present invention is shown, and the preparation method includes the following steps:

[0022] Step S01: preparing a colloid containing rare earth elements yttrium and europium or a colloid containing rare earth elements yttrium and terbium;

[0023] Step S02: Prepare conductive oxide Zn 1-x al x O (AZO) colloid;

[0024] Step S03: mixing the colloid in step S01 and the colloid in step S02 to form a mixed colloid;

[0025] Step S04: The mixed colloid coating of step S03 is obtained to contain conductive oxide Zn 1-x al x O doped rare earth element yttrium oxide luminescent film.

[0026] In the preparation method of the present invention, in the step S01, a compound of yttrium and europium or a compound of yttrium and terbium is selected and configured to form a doping concentration of europiu...

Embodiment 1

[0033] At room temperature, accurately weigh 18.7675g Y(NO 3 ) 3 ·6H 2 O and 0.4461g Eu(NO 3 ) 3 ·6H 2 O was dissolved in deionized water, and 100 mL of 0.5 mol / L Y and Eu aqueous solution doped with 2% Eu was prepared. Measure 8 mL of Y and Eu aqueous solutions with a concentration of 0.50 mol / L, add 32 mL of absolute ethanol as a solvent, add 7.6856 g of citric acid and 2 g of polyethylene glycol 8000, and stir for 6 hours in a water bath at 40 ° C to obtain a clear Y , Eu precursor solution, and aging the obtained precursor solution in an oven at 90°C for 60 hours to form a uniform colloid containing Y and Eu.

[0034] At room temperature, accurately weigh 0.5460g Zn(CH 3 COO) 2 2H 2 O, 0.0047g Al(NO 3 ) 3 9H 2 O and 0.4mL C 6 h 15 o 3 N is placed in a container, and a mixed solution of ethanol and water with a volume ratio of 4:1 is added to 50mL, and after stirring for 5h in a water bath at 40°C, a uniform precursor solution is obtained, and the obtained pre...

Embodiment 2

[0038] At room temperature, accurately weigh 37.9180g Y(NO 3 ) 3 ·6H 2 O and 0.4441g Eu(NO 3 ) 3 ·6H 2 O was dissolved in deionized water, and 100 mL of 1 mol / L Y and Eu aqueous solution doped with 1% Eu were prepared. Measure 4 mL of Y and Eu aqueous solution with a concentration of 1 mol / L, add 1 mL of deionized water and 35 mL of absolute ethanol as a solvent, add 3.0742 g of citric acid and 5 g of polyethylene glycol 10000, and stir for 4 h under the condition of a water bath at 60 ° C. A clear Y and Eu precursor solution was obtained, and the obtained precursor solution was aged in an oven at 90° C. for 40 h to form uniform Y and Eu colloids.

[0039] At room temperature, accurately weigh 2.1292g Zn(CH 3 COO) 2 2H 2 O, 0.1125g Al(NO 3 ) 3 9H 2 O and 0.6mL C 2 h 7 NO was placed in a container, and ethylene glycol methyl ether was added to 50 mL. After stirring for 4 hours in a water bath at 60°C, a clear precursor solution was obtained. The obtained precursor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com