Sample feeding apparatus for ultra-high vacuum test

An ultra-high vacuum and sample delivery technology, which is applied in the preparation of test samples, analysis materials, instruments, etc., can solve the problems of difficult manufacturing, complex structure, low test efficiency, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

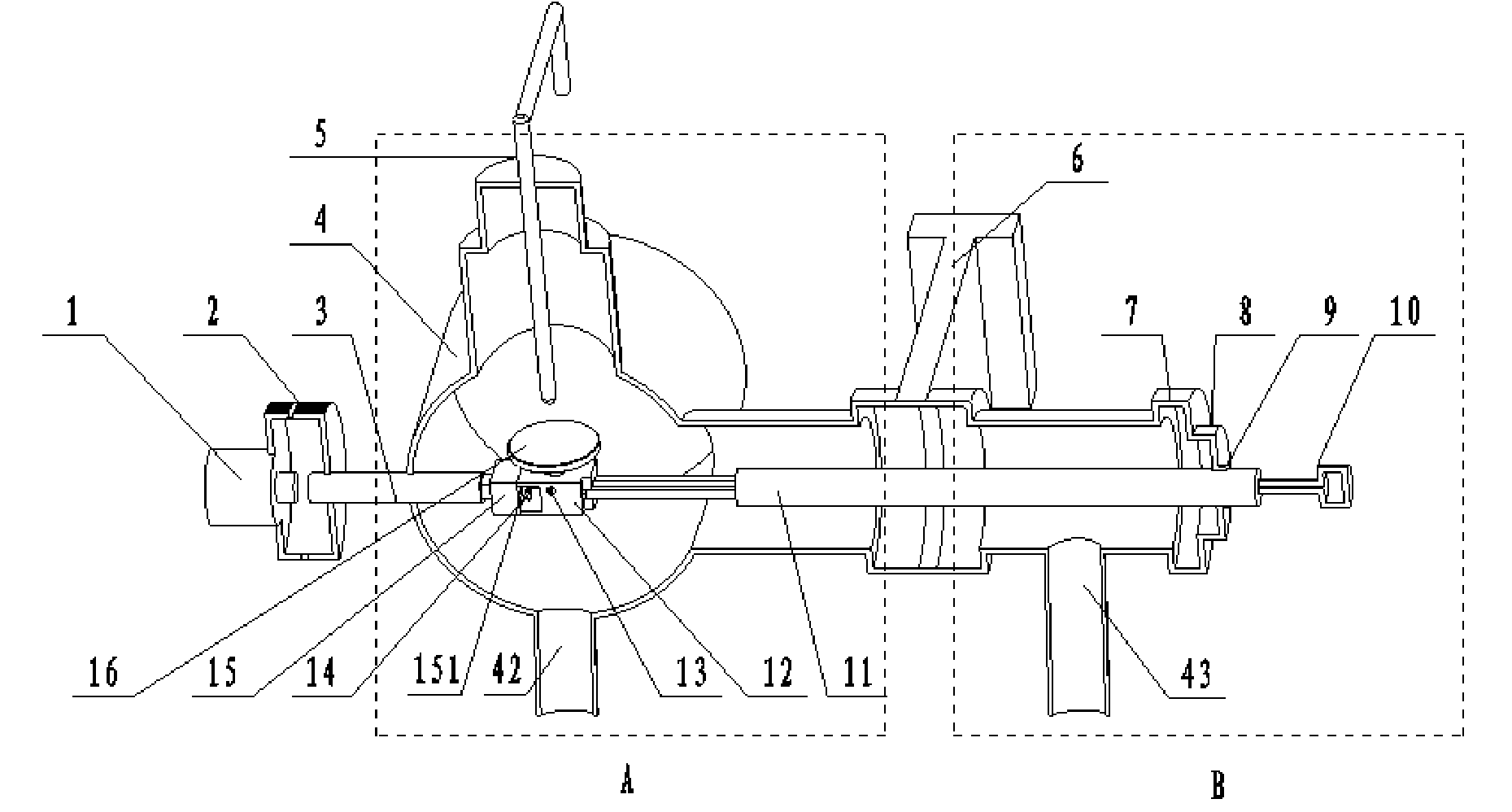

[0043] A sample delivery device for ultra-high vacuum testing of the present invention will be further described in detail below in conjunction with the accompanying drawings.

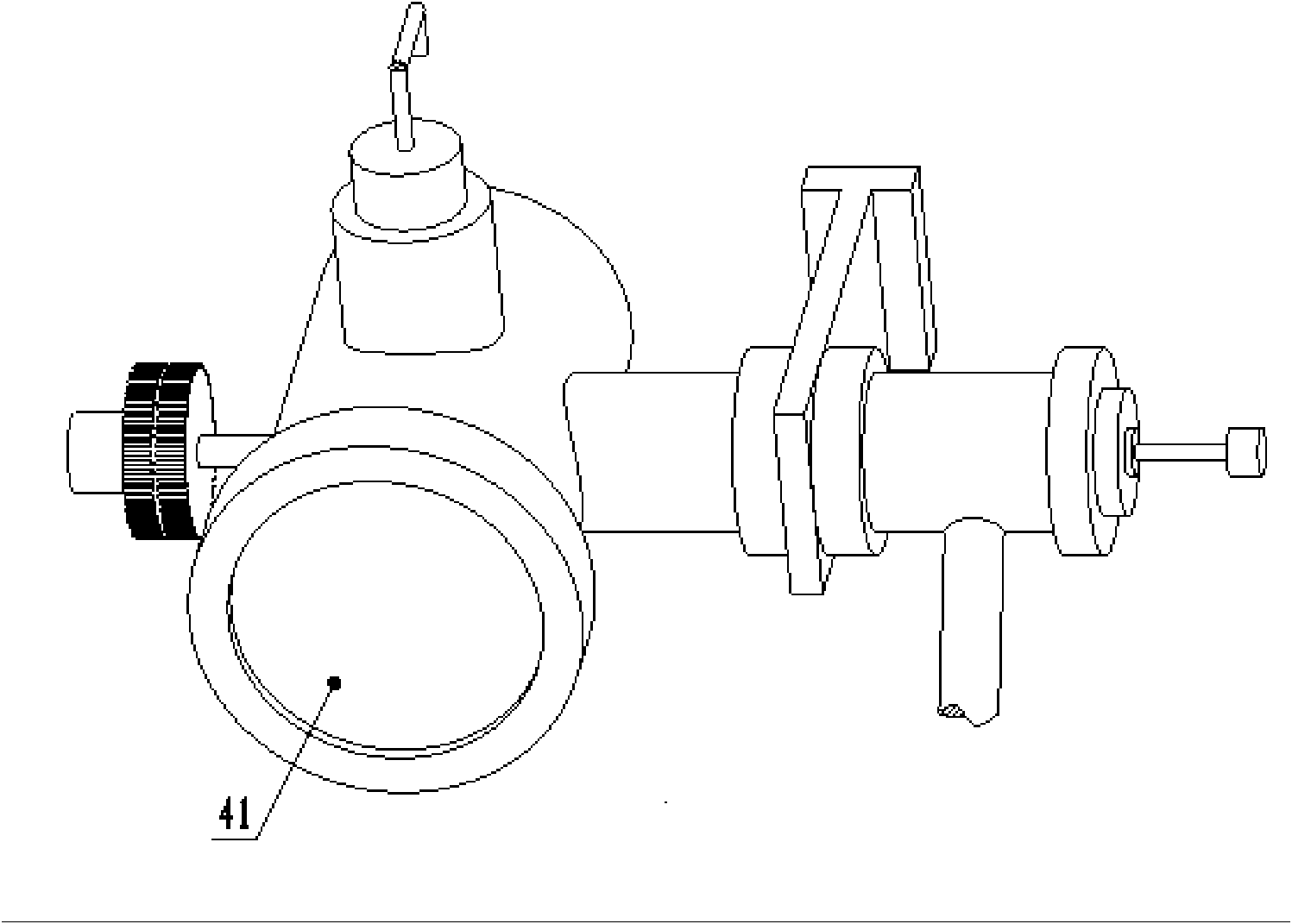

[0044] figure 1 Shown is a schematic view of the appearance of a sample delivery device for ultra-high vacuum testing.

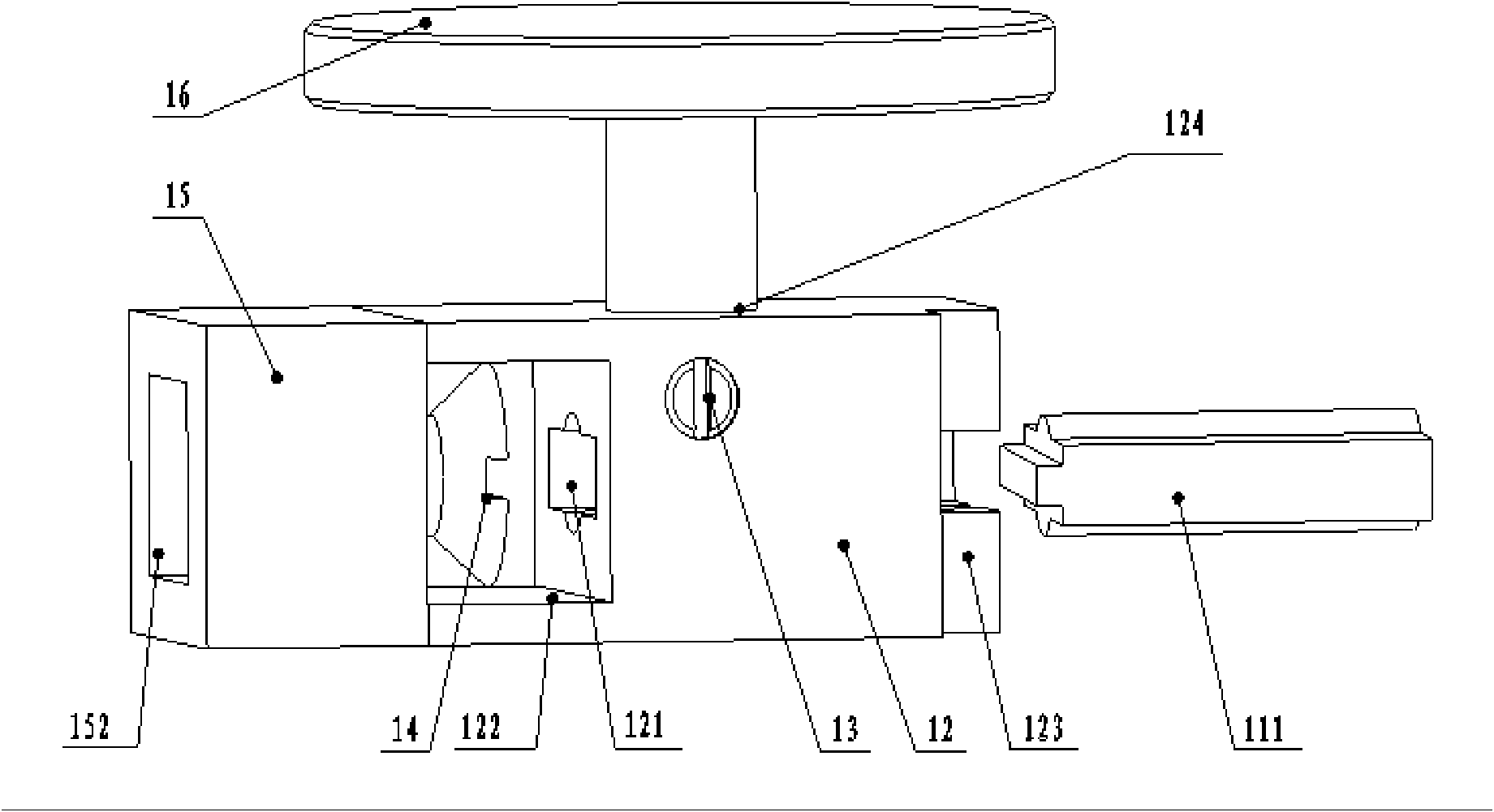

[0045]A sample delivery device for ultra-high vacuum testing, including a sample angle rotating wheel 1, a dial 2, a sample joint connecting rod 3, a vacuum tank 4, a test probe 5, a plug valve 6, and a low vacuum connecting flange 7 , sample feeding guide rod connection flange 8, sample feeding sealing cover 9, sample feeding adjustment handwheel 10, sample feeding rod 11, sample seat 12, sample fixing pin 13, sample connecting head connecting screw 14, sample connecting head 15, Sample 16. The sample 16 is placed in the sample placement hole 124 of the sample holder 12 , and the height adjustment of the sample 16 is realized through the asymmetrically arranged pins 13 on both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com