Device and method for measuring radar reflection characteristic of plasma coating material

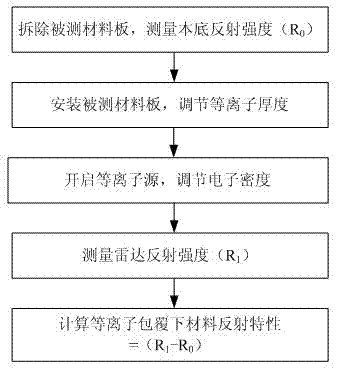

A plasma and radar reflection technology, which is used in measurement devices, analytical materials, and material analysis using radiation diffraction. Measure the effect of accurate, uniform plasma coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

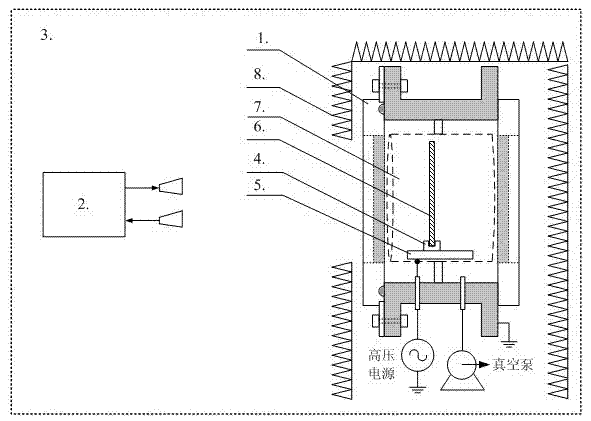

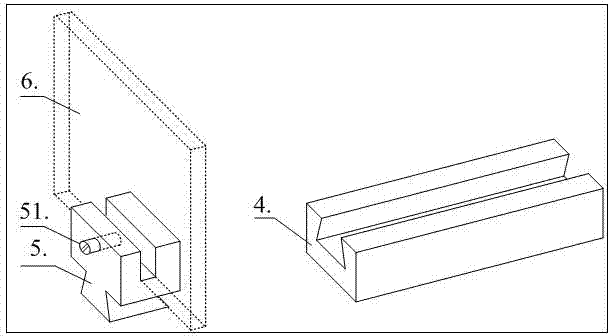

[0034] A device for measuring radar reflection characteristics of plasma-coated materials, including: a large-area uniform non-magnetized plasma generating unit 1, a radar scattering cross-section measuring mechanism 2, a microwave anechoic chamber 3, a supporting guide rail 4, a supporting slider 5, and a material plate to be tested 6 , microwave absorbing material 8, large-area uniform non-magnetized plasma generating unit 1, radar cross-section measuring mechanism 2 fixed in the microwave anechoic chamber 3, large-area uniform non-magnetized plasma generating unit 1 surrounded by a wave-absorbing material 8 in a space , the wave-absorbing material 8 has a window, so that the measured material plate 6 of the large-area uniform non-magnetized plasma generating unit 1 faces the radar cross-section measuring mechanism 2 directly.

Embodiment 2

[0036] refer to figure 1, a device for measuring radar reflection characteristics of plasma-coated materials, including: a large-area uniform non-magnetized plasma generating unit 1, a radar cross-section measuring mechanism 2, a microwave anechoic chamber 3, a supporting guide rail 4, a supporting slider 5, and a material plate to be tested 6. Wave-absorbing material 8, large-area uniform non-magnetized plasma generating unit 1, radar cross-section measuring mechanism 2 fixed in microwave anechoic chamber 3, large-area uniform non-magnetized plasma generating unit 1 surrounded by wave-absorbing material 8 in a space Inside, the wave-absorbing material 8 has a window, so that the measured material plate 6 of the large-area uniform non-magnetized plasma generating unit 1 directly faces the radar cross-section measurement mechanism 2, and the measured material plate 6 is fixed by the supporting guide rail 4 and the supporting block 5. In the cavity of the large-area uniform non-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com