Three-phase relative permeability testing method based on CT (computed tomography) scanning

A technology of relative permeability and CT scanning, which is applied in the field of physical simulation test devices for core oil reservoirs to achieve the effects of easy operation, intuitive results and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

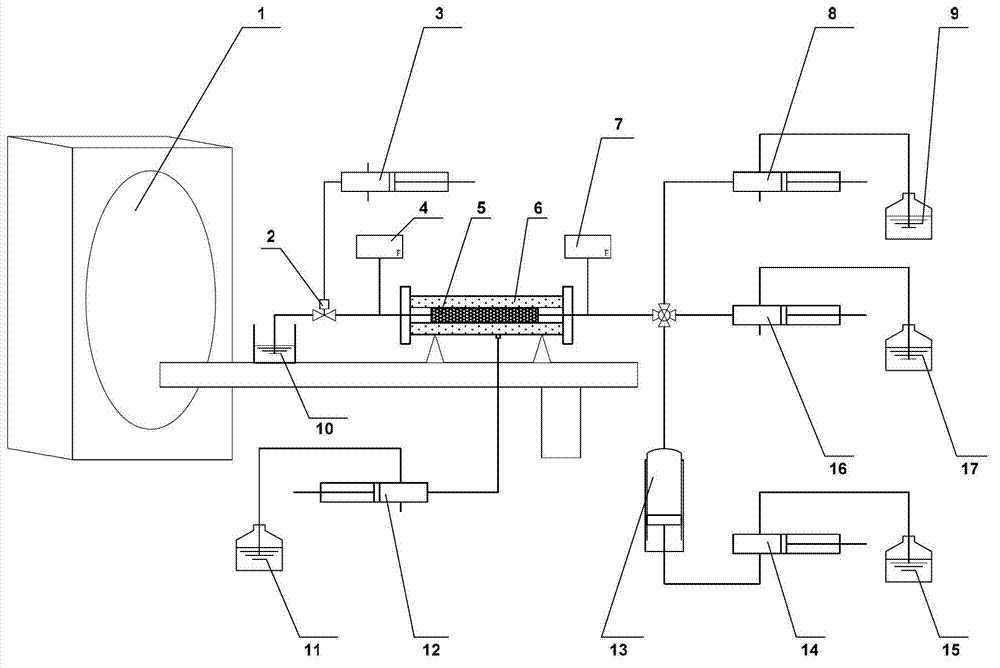

[0064] Embodiment 1: Three-phase relative permeability test system based on CT scanning.

[0065] Please refer to figure 1 , a test system in a preferred embodiment of the present invention includes a CT scanner 1, a core holder 6, a confining pressure system, an injection system and a back pressure control system. The core holder 6 is made of polyether ether ketone resin (PEEK) material, with a maximum pressure resistance of 30MPa and a maximum temperature resistance of 150°C. An inlet pressure gauge 7 is arranged at the inlet of the core holder 6, and an outlet pressure gauge 4 is arranged at the outlet. The inlet end of the core holder 6 is connected to the injection system, and the injection system is composed of an oil injection system, a water injection system and a gas injection system. The oil injection system includes an oil pump 8 and an oil storage container 9 , the water injection system includes a water pump 16 and a water storage container 17 , and the gas inje...

Embodiment 2

[0066] Embodiment 2: Use the device of Embodiment 1 to carry out the three-phase relative permeability test method. Specific steps are as follows:

[0067] 1) The core is loaded into the core holder, and the confining pressure is applied;

[0068] 2) Scan the dry core sample under two scanning voltages, record the scanning position and scanning conditions, and obtain the CT value of the dry core under the two energies;

[0069] 3) After the core is 100% evacuated and saturated with brine, the core is scanned under the same two scanning voltages, scanning conditions and scanning positions as in step 2), and the core CT value of fully saturated brine under two energies is obtained;

[0070] 4) During the displacement experiment, scan the core under the same two scan voltages, scan conditions and scan positions as in step 2), and obtain the CT values of the core under the two energies at that moment;

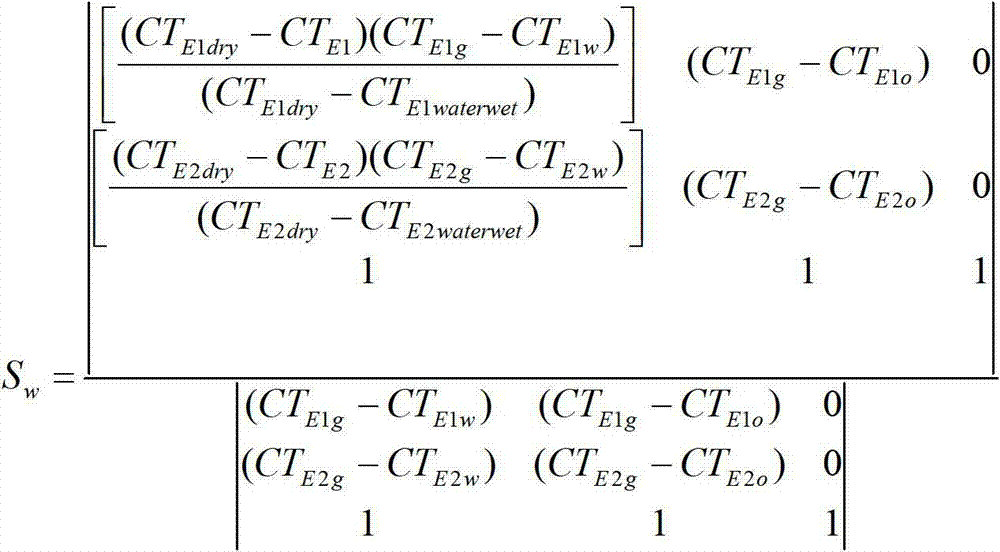

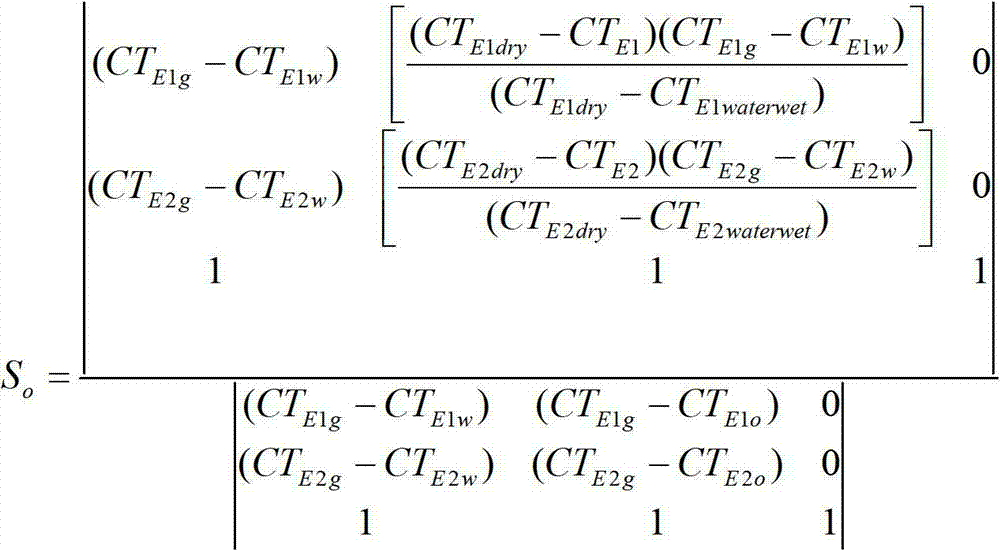

[0071] 5) Scan the air, experimental brine, experimental oil and experimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com