Temperature sensor as flip chip on a printed circuit board

A temperature sensor and circuit board technology, which is applied to thermometers, thermometers, instruments, etc. that use electric/magnetic components that are directly sensitive to heat, can solve problems such as unfavorable response time and variable measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

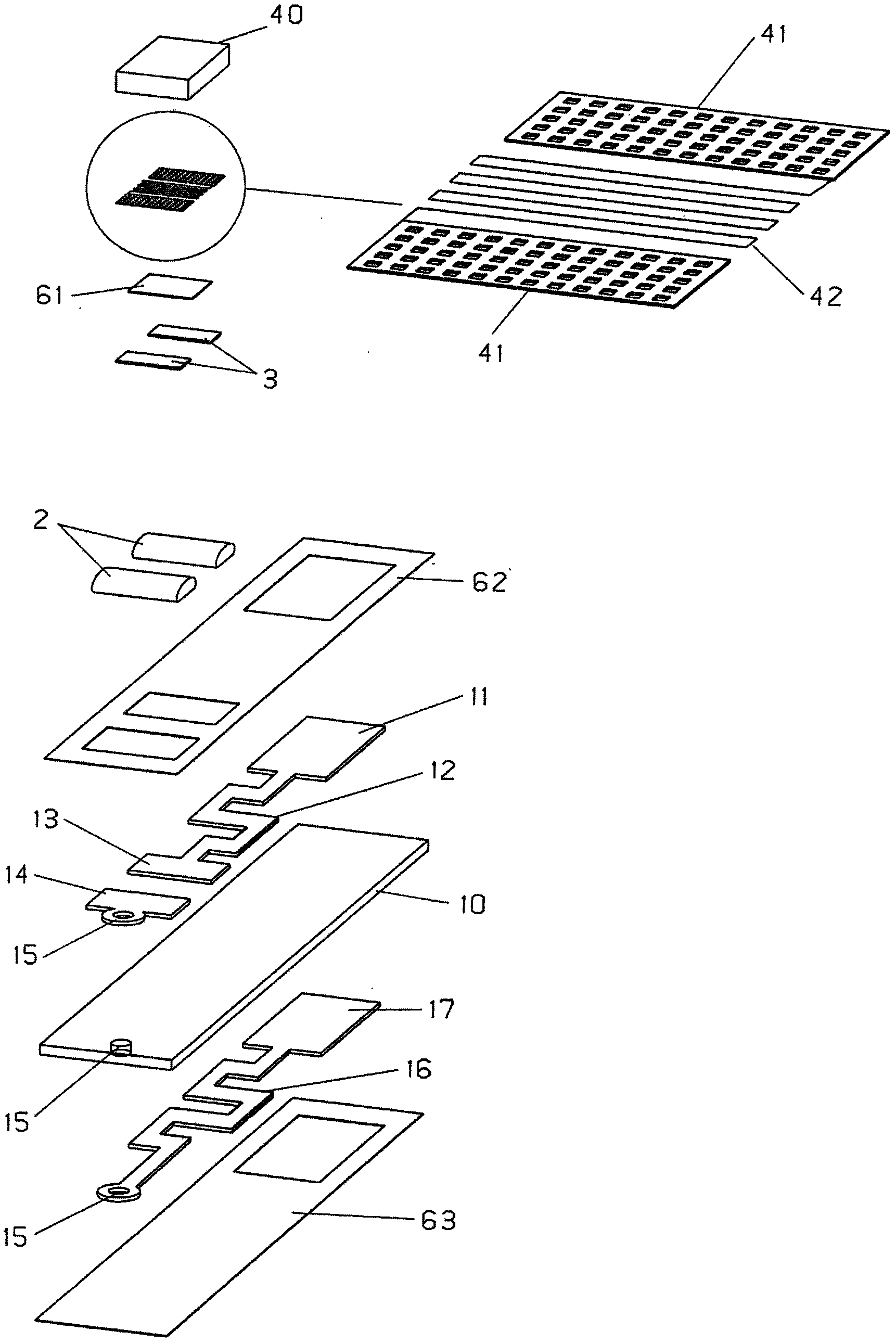

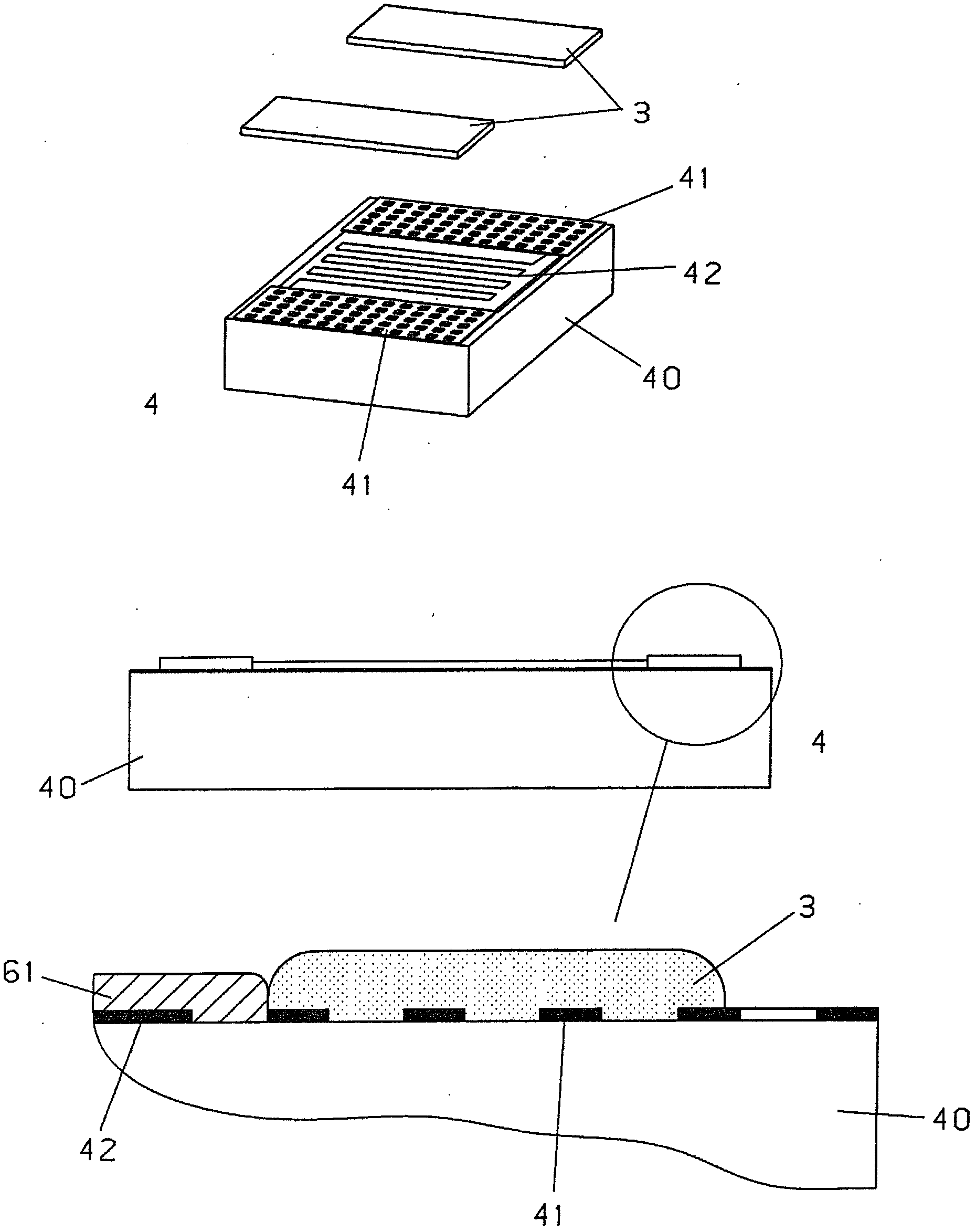

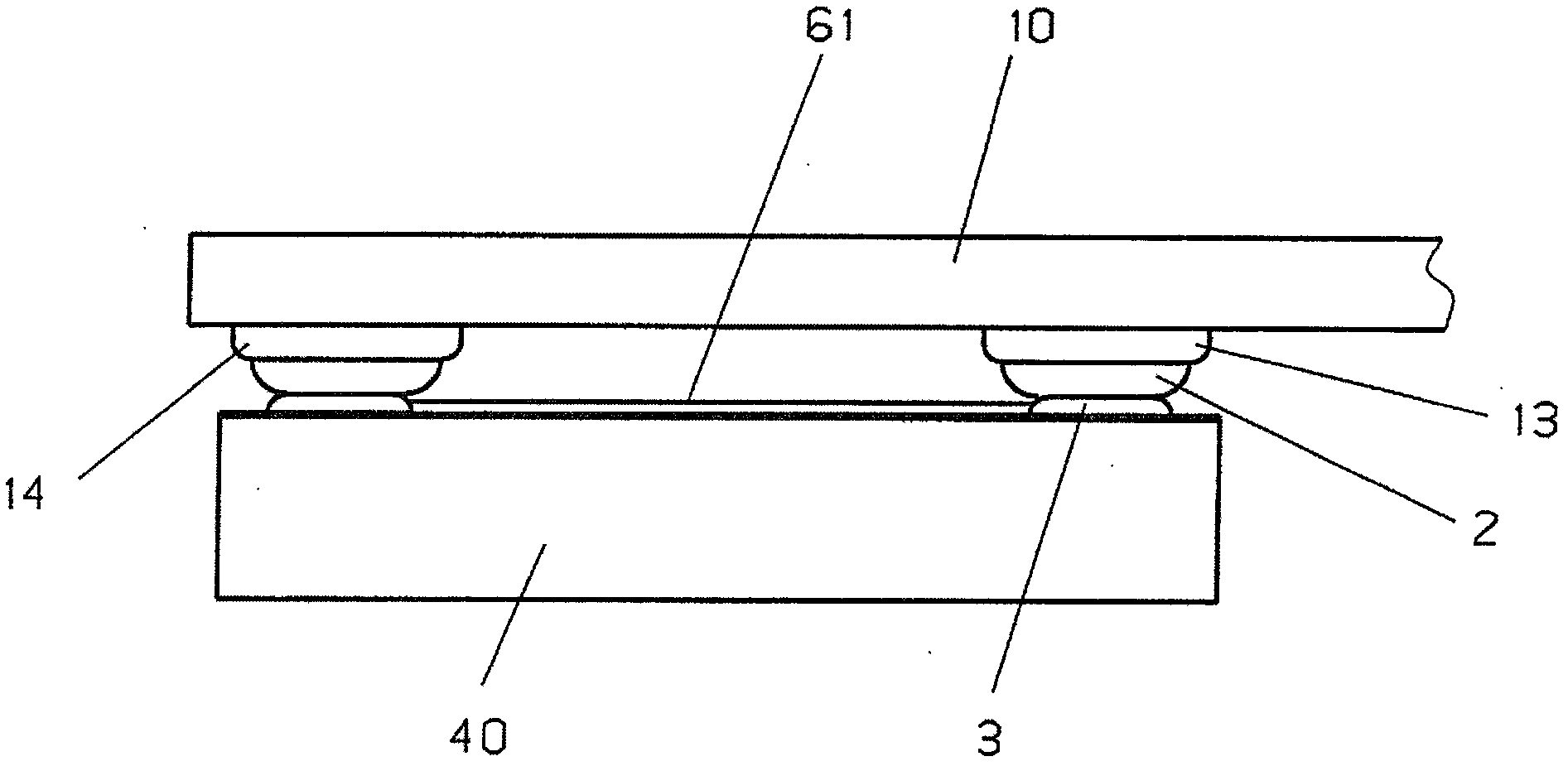

[0056] A piece of 300 mm x 150 mm x 0.4 mm BT epoxy resin foil 10 plated with 50 μm copper on both sides and reinforced with glass fibers was processed into 1000 larger units 1 of 15 mm x 3 mm. Here, each unit 1 is provided with a contact spread 15 at one end and with a larger contact area 11, 17 of 3.5 x 2.5 mm on the front and back at the other end. The larger contact area 11 is connected to the smaller contact area 13 via a guide rail 12 in a meandering manner. On the opposite side, the contact expansion 15 is connected to the larger contact area 17 via meander-shaped guide rails 16 . Two smaller contact areas 13 , 14 of 1.5 mm extending in the longitudinal direction of the printed circuit board 1 are provided on the front side and are bridged by the flip chip 4 . The contact extension 15 is arranged on one of the smaller contact areas 14 .

[0057] The contact area is plated with soft solder 2. The soft solder 2, in particular the smaller contact areas 13, 14, contains ...

Embodiment 2

[0063] A piece of 150 mm x 100 mm x 0.3 mm BT epoxy resin foil coated with 50 μm copper on both sides and reinforced with glass fibers was processed into 500 smaller units 1 , in particular with dimensions of 10 mm x 2.5 mm. Here, each unit 1 is provided with a contact spread 15 at one end and with a larger contact area 11 , 17 of 2.5×2 mm on the front and back at the other end. On the opposite side, the contact extension 15 is connected to the contact area 17 via the guide rail 16 . Two smaller contact areas 13 , 14 of 1 mm extending in the longitudinal direction of the printed circuit board 1 are provided on the front side and are bridged by the flip chip 4 . During the processing of the copper coating, the smaller contact area 13 in this area is connected to the larger contact area 11 via the guide rail 12 . The current spreader 15 is formed outside the small contact region 14 . A linear, 1 mm wide guide rail 16 is formed between the contact extension 15 and the larger co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com