Synchronously operating jet type bottle cavity drying device and method

A technology of synchronous operation and drying device, which is applied to the drying field of the inner cavity of food packaging containers, can solve the problems of no air drying, short drying time, poor drying effect, etc., and achieves saving hot air source, good drying effect and drying effect. effect of time extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

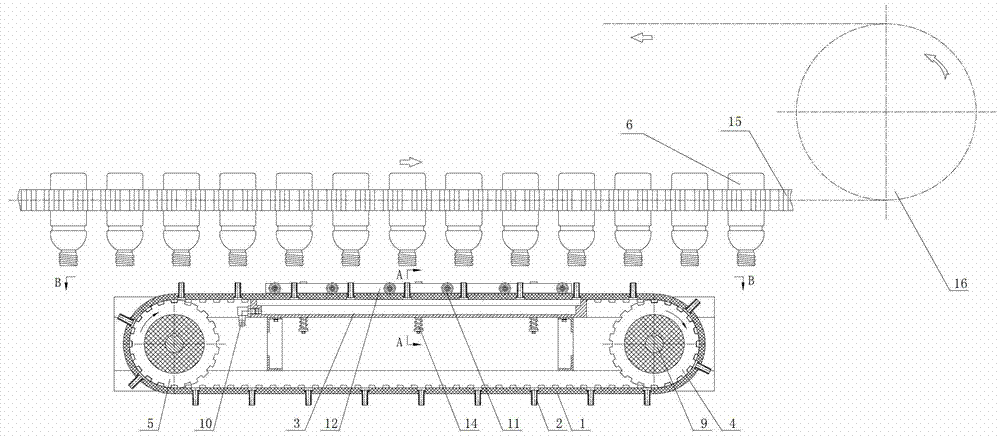

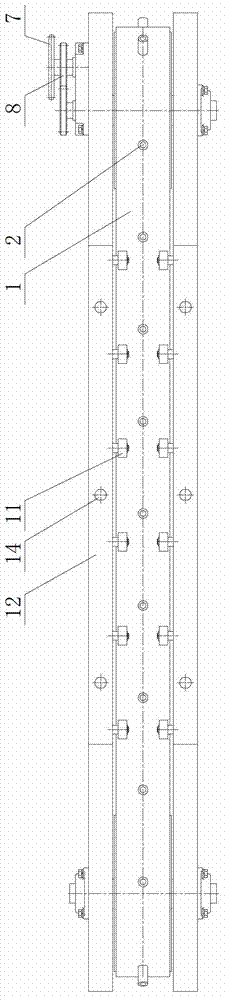

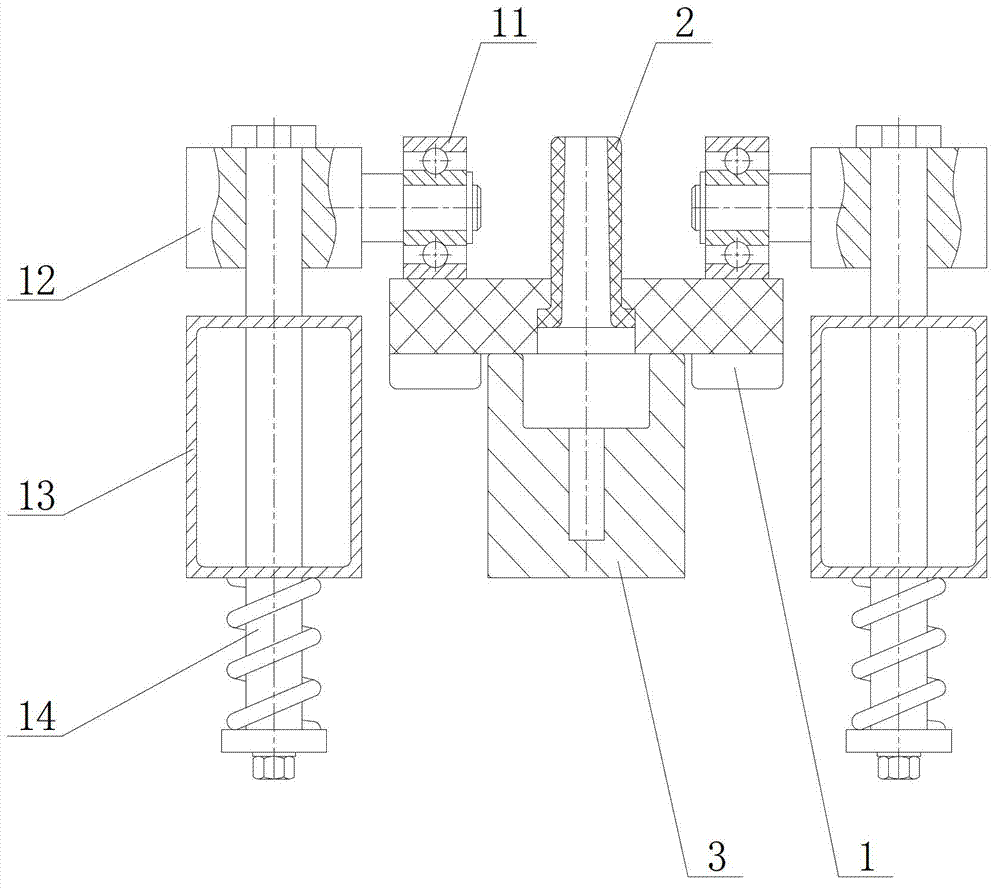

[0041] In this embodiment, a synchronously running spray type bottle chamber drying device, such as figure 1 or figure 2 As shown, it includes a synchronously running bottle clamping mechanism and a synchronous belt spraying mechanism. The bottle clamping mechanism is arranged above the timing belt spraying mechanism; 2 and long groove air chamber 3, the two ends of the synchronous belt are respectively connected with the synchronous belt pulley, the synchronous belt wheel at one end is used as the driving wheel 4, and the synchronous belt wheel at the other end is used as the driven wheel 5, and the driving wheel is connected with the synchronous belt drive assembly , a plurality of nozzles 2 are distributed on the timing belt 1, and the long groove air chamber 3 is located under the timing belt between the two timing pulleys, and each nozzle 2 above the long groove air chamber is clamped with the bottle clamping mechanism. The 6 bottle mouths of each bottle held correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com