Induction cooker with novel radiating structure

A heat dissipation structure and technology of induction cooker, applied in the field of induction cooker, can solve problems such as lack of heat dissipation space, electrical failure of the cooker, influence on lifespan, etc., and achieve the effect of compact structure, convenient maintenance and elimination of machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

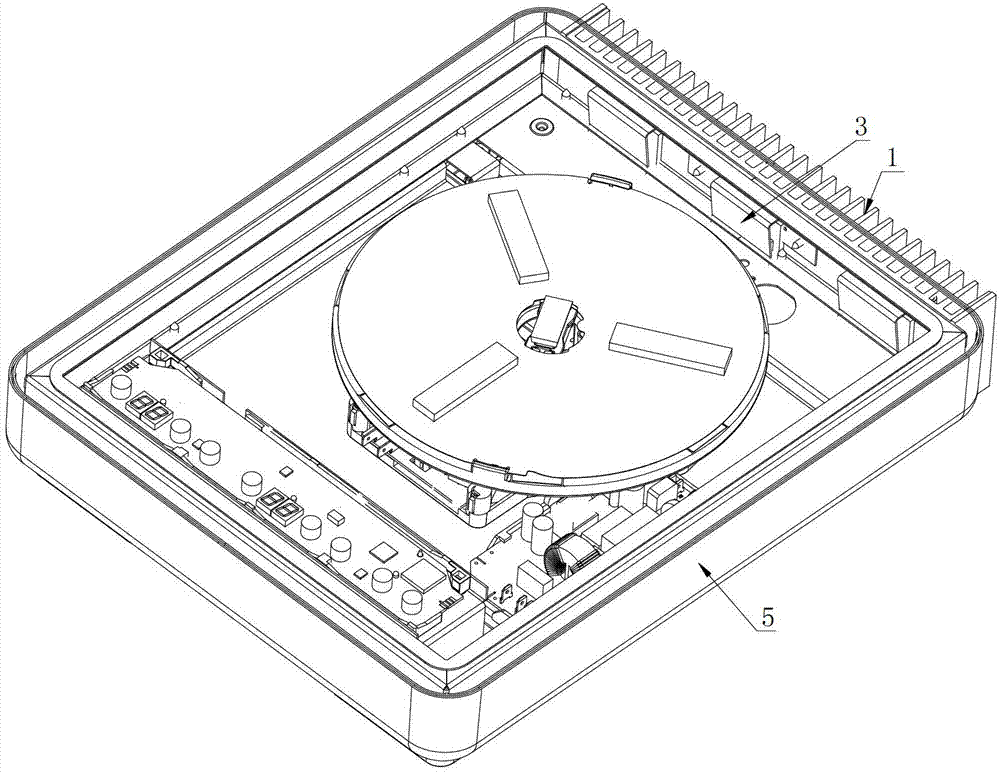

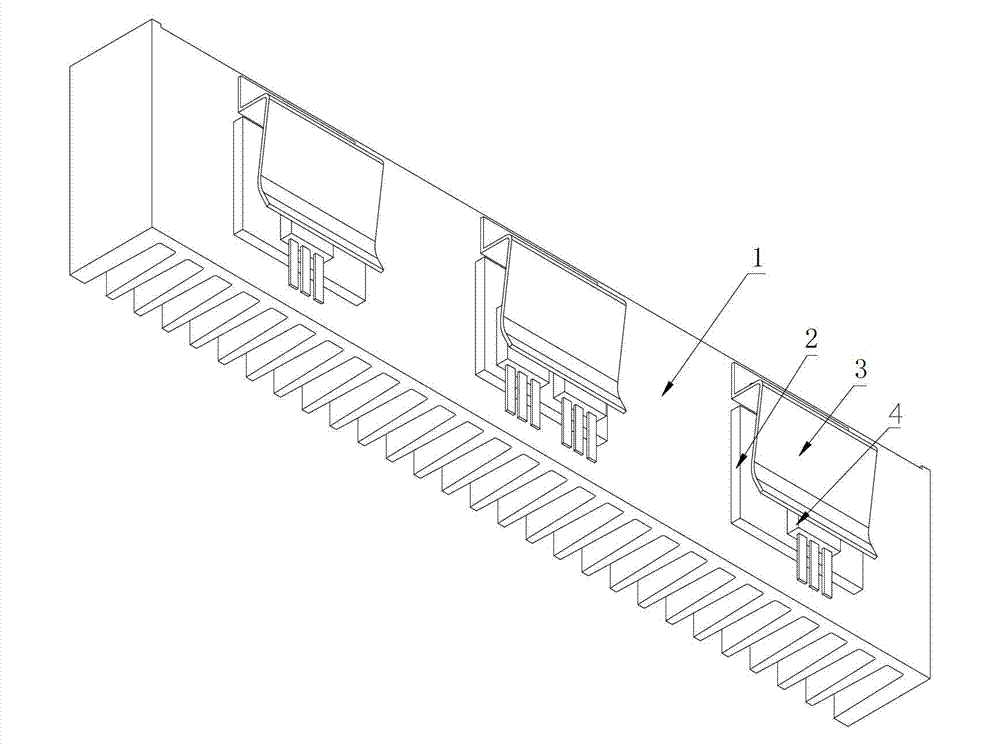

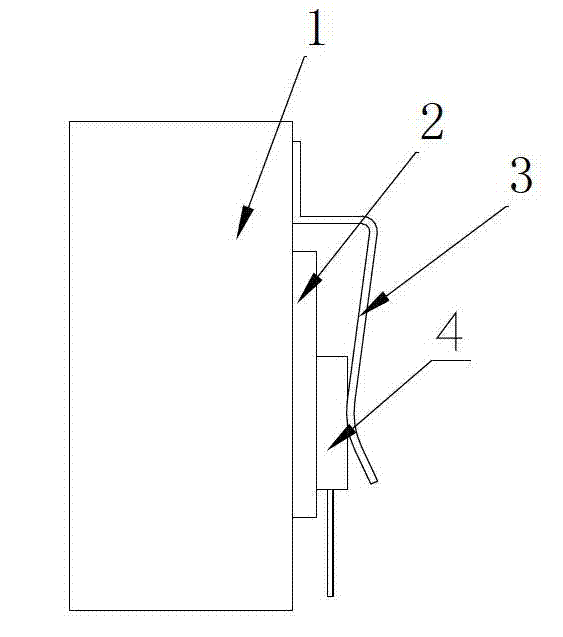

[0024] see Figure 1 to Figure 4 and Figure 6 In the present invention, a heat dissipation plate 1 is arranged on one side of the furnace body 5 of the induction cooker, the hot end surface of the semiconductor heat sink 2 is attached to the inner surface of the heat dissipation plate 1, and the heating element 4 is fixed on the cold end surface of the semiconductor heat sink 2 by a fixed elastic piece 3 Above; the fixed part of the fixed elastic piece 3 is set on the heat dissipation plate 1 above the corresponding semiconductor heat sink 2, and the abutment part below the fixed elastic piece 3 is located on the outer surface of the heating element 4, so that the heating element 4 is clamped on the semiconductor On the heat sink 2 , an auxiliary PCB board 7 is additionally provided on the bottom plate of the furnace body below the corresponding heating element 4 . Considering that the heating element 4 is mainly the IGBT and the rectifier bridge, the heat generation of othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com