Charging heat-accumulating device of Stirling engine

A Stirling engine and heat storage device technology, which is applied to hot gas variable displacement engine devices, machines/engines, mechanical equipment, etc., can solve the problems of heating devices without heat, storage, and heat cannot be continuously supplied, so as to prevent The heat storage medium overflows and the effect of good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

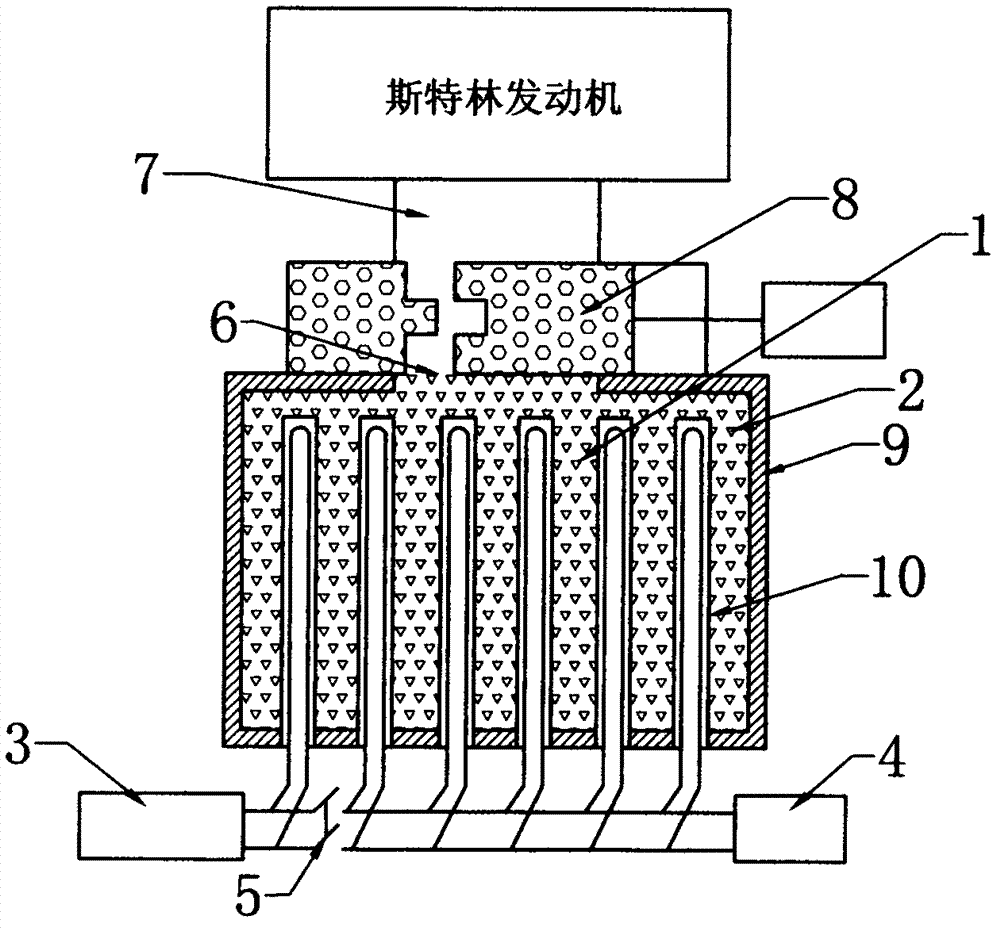

[0023] like figure 1 As shown, the charge heat storage device of the Stirling engine of the present invention includes a heat storage chamber 1, an insulation layer 9 is arranged outside the heat storage chamber, molten salt 2 is housed in the heat storage chamber, and a plurality of An electric heating device 10 composed of electric heating tubes; the electric heating device is arranged in two parts, one part is a low-power heating device with a small number of electric heating tubes, and the other part is a high-power heating device with a large number of electric heating tubes. It is connected with high-power power supply terminal 4, which can be used to connect to the power supply of a specially set high-power charging station for electric vehicles. The input end of the low-power electric heating device is connected to the low-power power supply terminal 3, which can be used to connect to ordinary civilian power supplies; the input end of the high-power heating device is c...

Embodiment 2

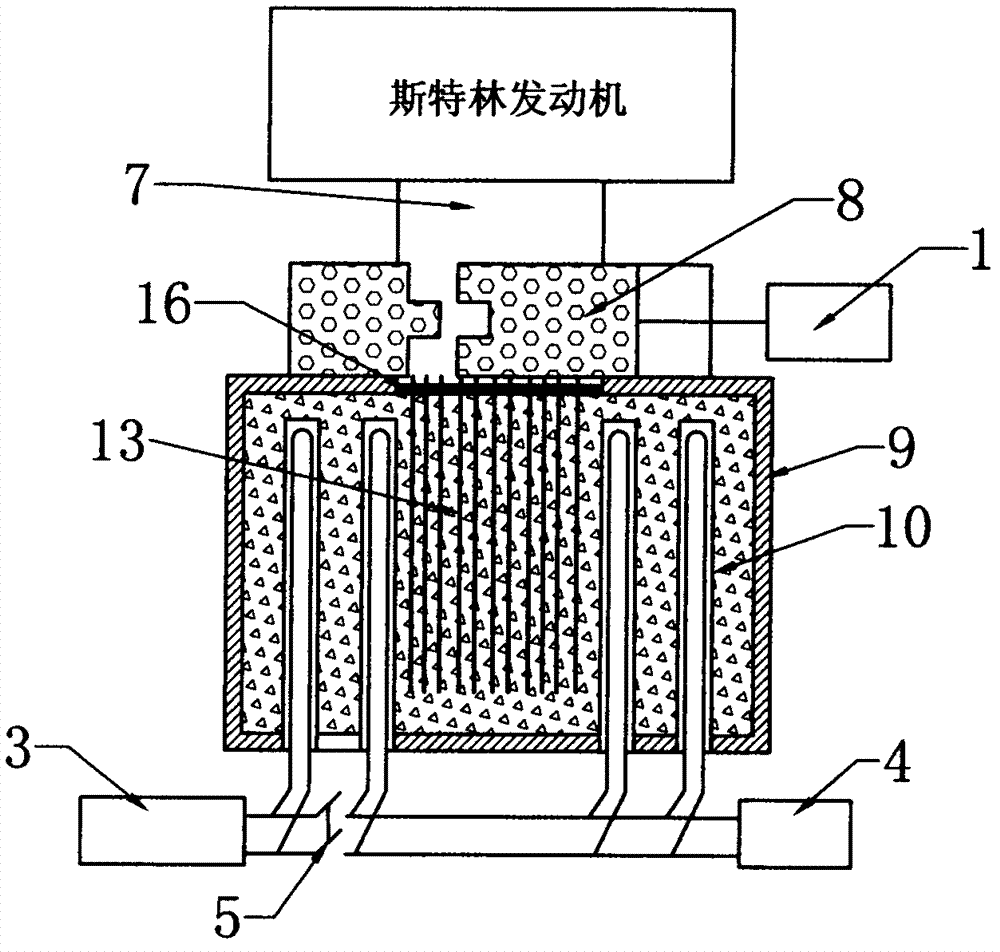

[0025] like figure 2 As shown, on the basis of the first embodiment, a partition 16 is further provided at the opening 6 of the heat storage cavity, and a heat sink 13 is provided on the partition.

Embodiment 3

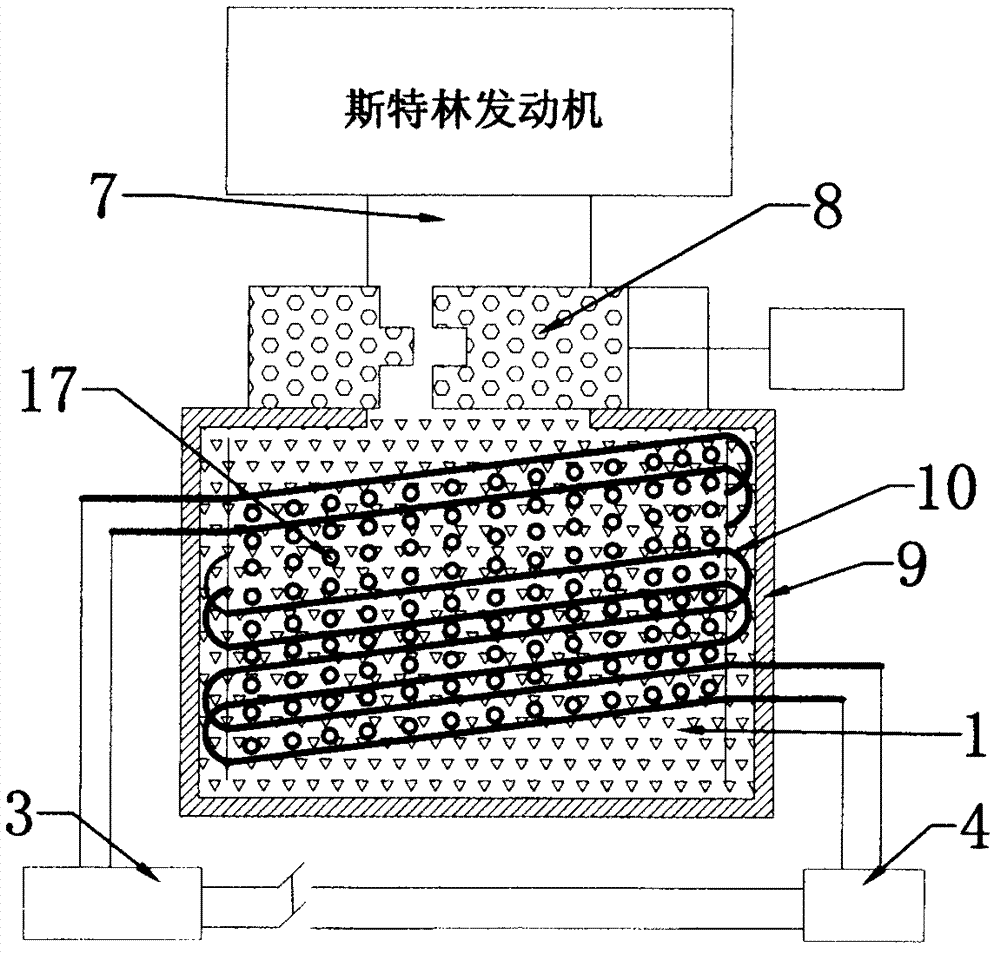

[0027] like image 3 As shown, the difference between it and Embodiment 1 is that the electric heating device 10 adopts intermediate frequency coils; the intermediate frequency coils are provided with two groups, one group is a low-power intermediate frequency coil, and the other group is a high-power intermediate frequency coil, respectively connected to the low-power power supply terminal and High-power power supply terminal; at the same time, a metal ball 17 is arranged in the intermediate frequency coil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com