Construction method of steel box column-concrete beam joint

A construction method and technology for concrete beams, which are applied in construction, building structure, processing of building materials, etc., can solve the problems of large construction interference, difficult and accurate transition, and high engineering cost, and achieve broad application prospects, simple operation, and simple construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

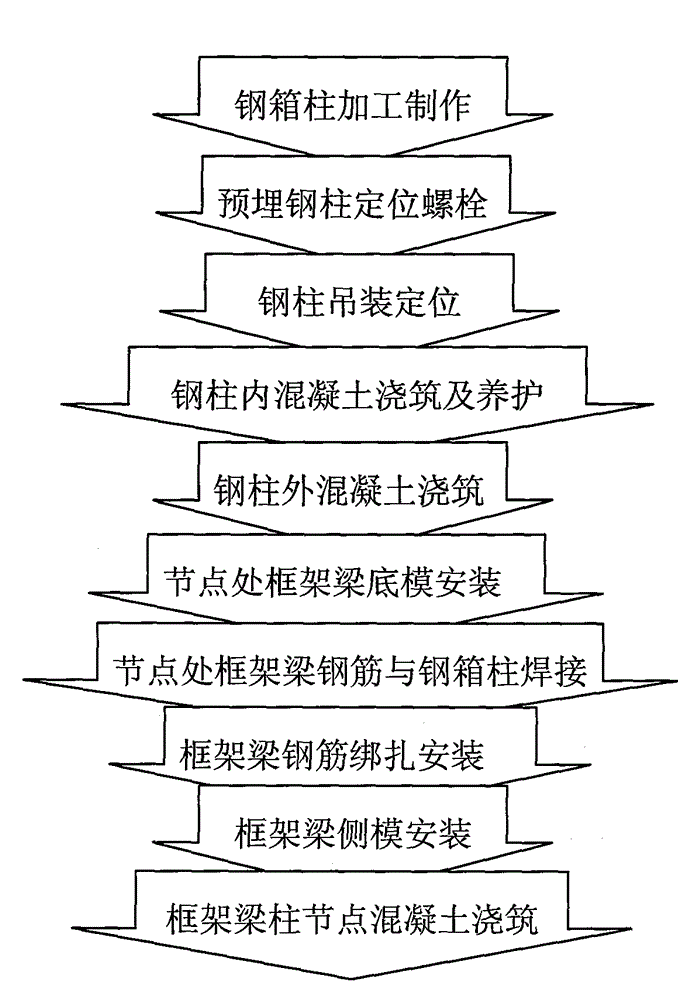

[0015] The construction methods are as follows: processing and fabrication of steel box columns, pre-embedded steel column positioning bolts, hoisting and positioning of steel columns, concrete pouring and curing inside steel columns, concrete pouring outside steel columns, bottom formwork installation of frame beams at joints, reinforcement of frame beams at joints Welding with steel box columns, binding installation of frame beam reinforcement, installation of frame beam side formwork, concrete pouring of frame beam column joints.

[0016] The specific construction process also includes: opening two 200×200mm square holes along the opposite side of the column centerline for concrete pouring at the foot of the steel column; A round hole with a diameter of 400mm is opened in the center; the connecting steel plate is connected with the steel column, the thickness is ≥30mm, the length of the connecting steel plate is the same as the width of the face column, and the width is not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com