Wettable cross-linked solidified liquid car polishing protection film coating agent as well as preparation method and construction method thereof

A technology of wet crosslinking and photoprotection, which is applied in the direction of surface coating liquid devices, polyurea/polyurethane coatings, pretreatment surfaces, etc., and can solve the problem of short gloss and protection time, no hydrophobicity and scratch resistance of the paint surface No damage, complex production process and other problems, to achieve a significant effect of brightening, improve self-cleaning, and more economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

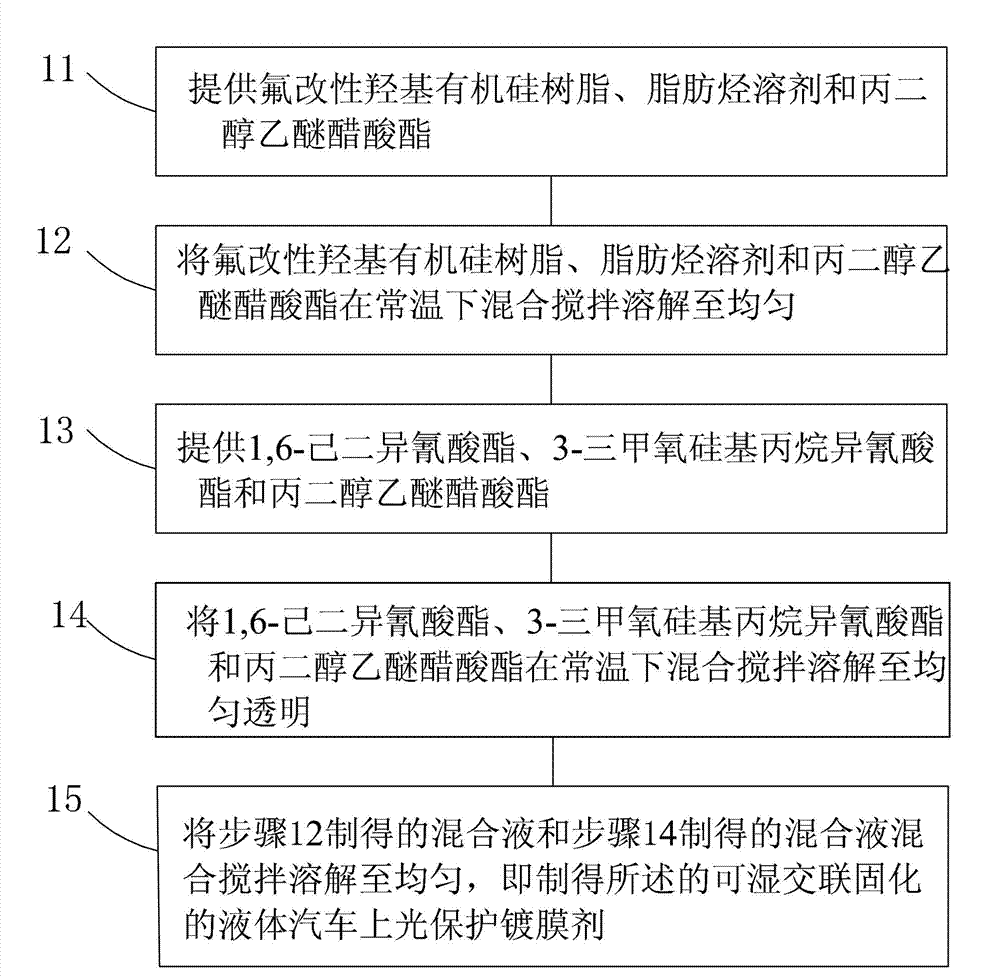

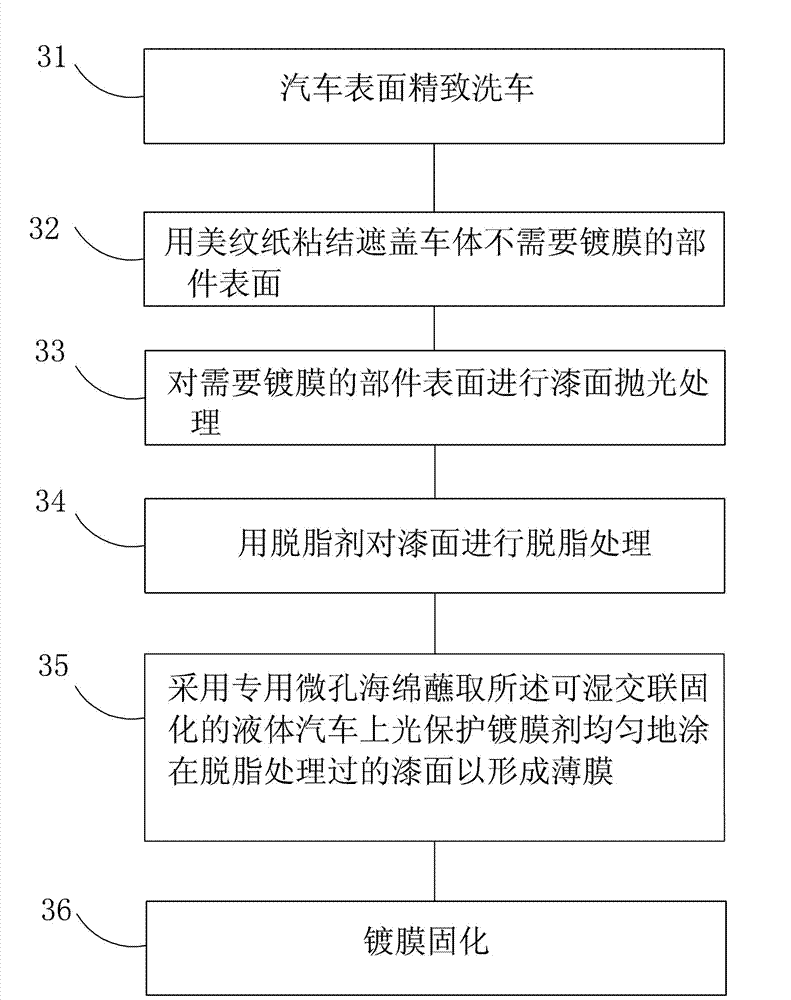

[0031] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail the preferred embodiments of the present invention and the accompanying drawings.

[0032] The present invention provides a wet-crosslinkable and curable liquid automotive glazing protective coating agent, which includes the following components and their weight percentages: fluorine-modified hydroxy silicone resin, 50%-60%; 1,6-hexamethylene diisocyanate, 6%-10%; 3-trimethoxysilyl propane isocyanate, 3%-5%; aliphatic hydrocarbon solvent, 20%-31%; propylene glycol ethyl ether acetate, 5%-10%.

[0033] The hydroxyl value of the fluorine-modified hydroxy silicone resin is 95-100 mgKOH / g, the mass percentage of fluorine in the fluorine-modified hydroxy silicone resin is 2-3%, and the viscosity is 1200-1400 cP.

[0034] The boiling range of the aliphatic hydrocarbon solvent is 160-200°C.

[0035] See figure 1 , The present invention also provides a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com