Method for preparing self-hardening furan resin for casting and mother liquor

A furan resin, self-hardening technology, applied in casting molding equipment, casting molds, manufacturing tools, etc., can solve the problems of production efficiency, high furfuryl alcohol addition, furan resin, etc., to achieve high production efficiency, low price, No secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

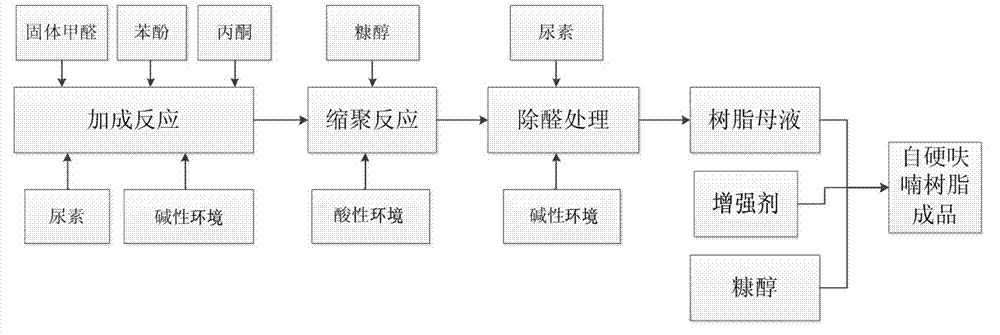

Method used

Image

Examples

Embodiment 1

[0019] The self-hardening furan resin mother liquor of the present embodiment adopts 10% by weight of acetone, 18% of phenol, 18% of solid formaldehyde, 4% of urea, and 50% of furfuryl alcohol as the main raw materials. The specific preparation method is as follows:

[0020] Prepared as follows:

[0021] 1) Add 10% acetone, 18% phenol, 18% solid formaldehyde and 2% urea (50% of the total urea) into the reactor, adjust the pH to 7.0 with sodium hydroxide, and react at 70°C for 1 hour ;

[0022] 2) Add 50% furfuryl alcohol when the system is cooled below 80°C, adjust the pH to 4.0 with phosphoric acid, and react at 80°C for 1.5 hours;

[0023] 3) Adjust the pH to 7.0 with sodium hydroxide, add the remaining 2% urea, and react at 80°C for 0.5 hours;

[0024] 4) Lower the temperature to below 40°C to obtain the no-bake furan resin mother liquor.

[0025] The no-bake furan resin for casting in this example adopts the following method, using 40% of the no-bake furan resin mother ...

Embodiment 2

[0027] The self-hardening furan resin mother liquor of the present embodiment is prepared by using 16% by weight of acetone, 30% of phenol, 13% of solid formaldehyde, 0.5% of urea, and 40.5% of furfuryl alcohol as main raw materials. The specific preparation method is as follows:

[0028] Prepared as follows:

[0029] 1) Add 16% acetone, 30% phenol and 13% solid formaldehyde into the reaction kettle, adjust the pH to 7.5 with sodium hydroxide, and react at 80°C for 1.8 hours;

[0030] 2) Add 40.5% furfuryl alcohol after the system cools down to below 80°C, adjust the pH to 5.0 with phosphoric acid, and react at 95°C for 2 hours;

[0031] 3) Adjust the pH to 7.0 with sodium hydroxide, add 0.5% urea, and react at 80°C for 0.5 hours;

[0032] 4) Lower the temperature to below 40°C to obtain the no-bake furan resin mother liquor.

[0033] The no-bake furan resin for casting in this example adopts the following method, using 20% of the no-bake furan resin mother liquor prepared...

Embodiment 3

[0035] The self-hardening furan resin mother liquor of the present embodiment adopts 12% by weight of acetone, 16% of phenol, 25% of solid formaldehyde, 12% of urea, and 35% of furfuryl alcohol as main raw materials. The specific preparation method is as follows:

[0036] Prepared as follows:

[0037] 1) Add 12% acetone, 16% phenol, 25% solid formaldehyde and 9% urea (accounting for 75% of the total urea) into the reactor, adjust the pH to 8.0 with sodium hydroxide, and react at 90°C for 1 ~3 hours;

[0038] 2) Add 35% furfuryl alcohol after the system cools down to below 80°C, adjust the pH to 4.5 with phosphoric acid, and react at 100°C for 3 hours;

[0039] 3) Adjust the pH to 7.5 with sodium hydroxide, add the remaining 3% urea, and react at 85°C for 0.8 hours;

[0040] 4) Lower the temperature to below 40°C to obtain the no-bake furan resin mother liquor.

[0041] The no-bake furan resin for casting in this example adopts the following method, using 79.6% of the no-bak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com