Clamp for turning circular arc conical part

A tapered and turning technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of inconvenient installation and removal, poor use effect, and affecting processing efficiency, etc., to achieve convenient installation and removal, The effect of improving the use effect and improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described below in conjunction with accompanying drawing.

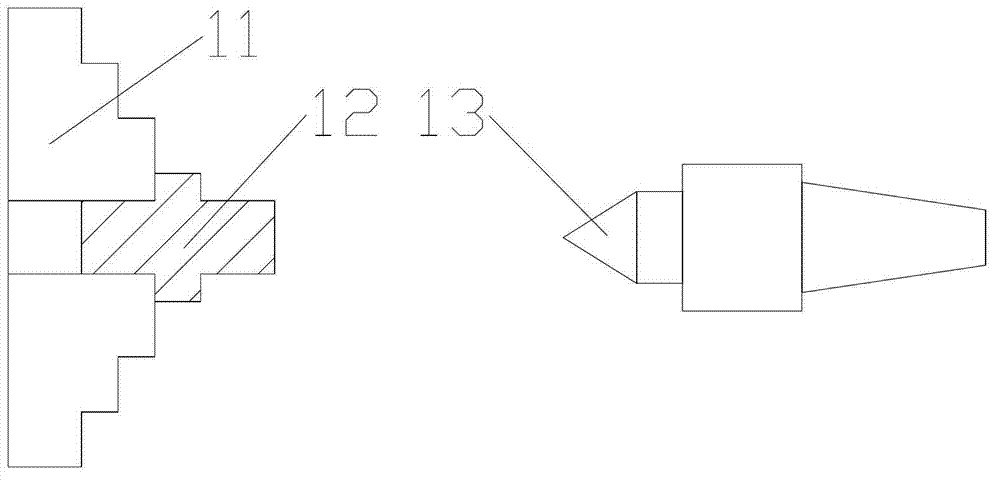

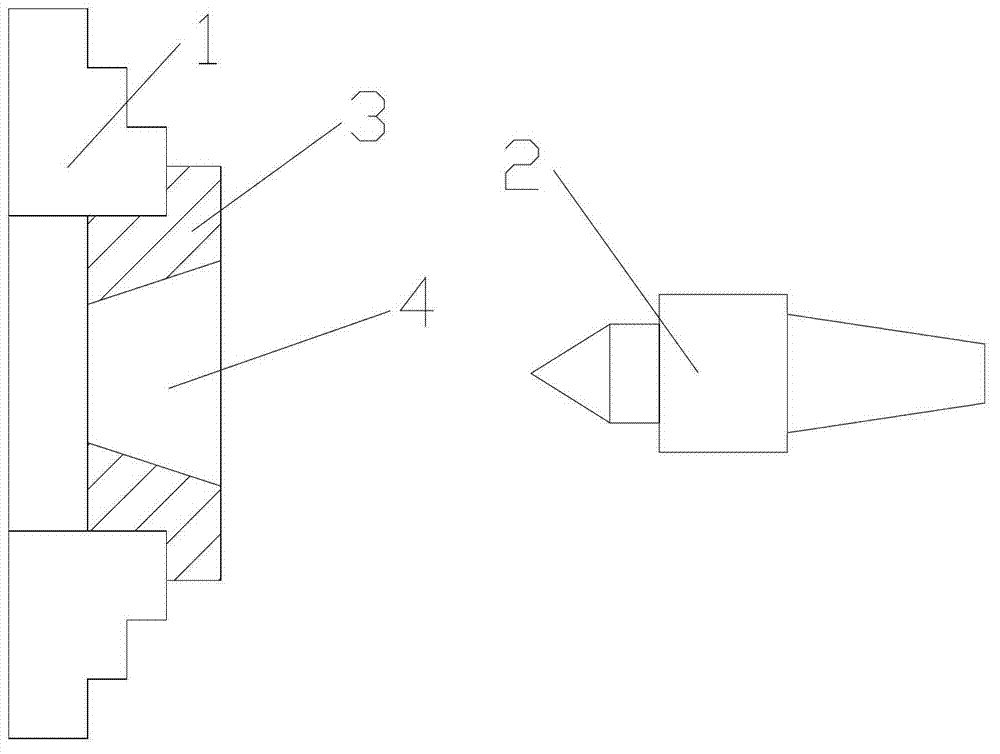

[0015] as attached image 3 A kind of fixture for arc-cone turning of the present invention shown, comprises three-jaw chuck 1 and machine tool tip 2, is provided with fixed sleeve 3 in comprising described three-jaw chuck 1; Said fixed sleeve The inner hole 4 of 3 is tapered; the section of the fixed sleeve 3 is "T"-shaped; the "-" of the "T"-shaped fixed sleeve 4 is in close contact with the three-jaw chuck 1.

[0016] as attached Figure 4 As shown in the present invention, a fixture for turning an arc-shaped conical part is used. When in use, the arc-shaped conical part 14 to be processed is inserted into the fixed sleeve 3, and then the center of the machine tool 2 is used to withstand the circular arc-shaped part to be processed. The head of the arc cone 14 realizes clamping. The fixture for turning arc-shaped conical parts of the present invention utilizes the frictional force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com