Pulsed cartridge filter

A filter cartridge dust collector, pulse-type technology, applied in the direction of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of filter barrel damage, staying in place, and tearing of filter material, etc. The effect of saving capacity and increasing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

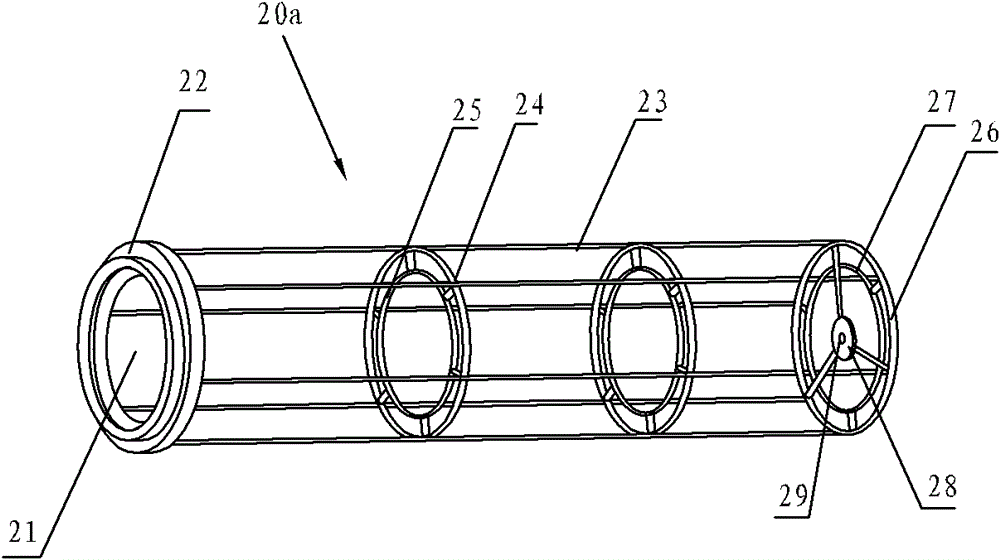

[0028] Such as figure 1 As shown, the pulse filter cartridge dust collector of the present invention includes a dust collector body 10, an air compressor 40 and a plurality of filter cartridges 20, the filter cartridges 20 are arranged in the dust collector body 10, and the upper end of the dust collector body 10 is set There is an air inlet 12, the lower end is provided with an air outlet 14, and the bottom is provided with an ash hopper 16; the pulse type filter cartridge dust collector can also include a plurality of pulse blowing pipes 48, a pulse signal generator (not shown), an air inlet circle Pipe 44 and decompression valve 42, each pulse injection pipe 48 is provided with a pulse electromagnetic valve 46, and communicates with filter cartridge 20 one by one respectively, a plurality of pulse injection pipes 48 can communicate with air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com