Improved carbon capture in fermentation

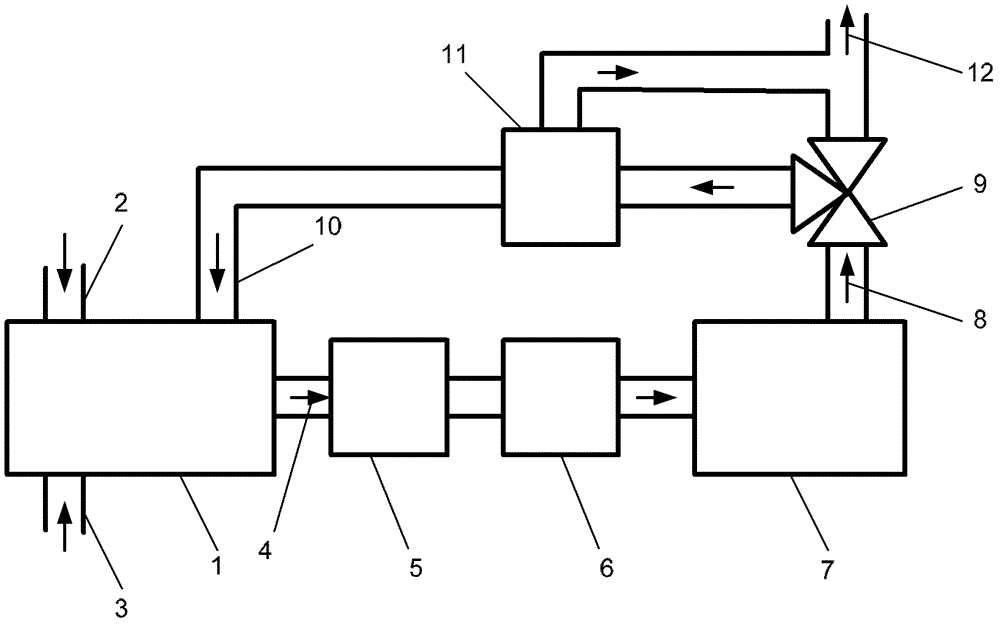

A carbon capture and fermentation process technology, applied in fermentation, biochemical instruments, biochemical equipment and methods, etc., can solve problems such as low capture efficiency and aggravated GHG emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

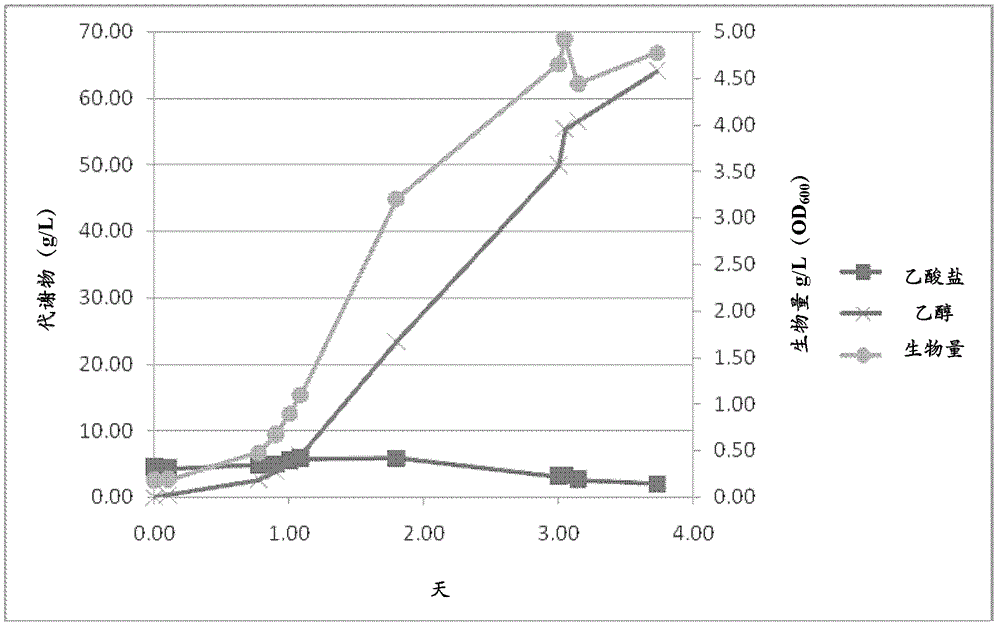

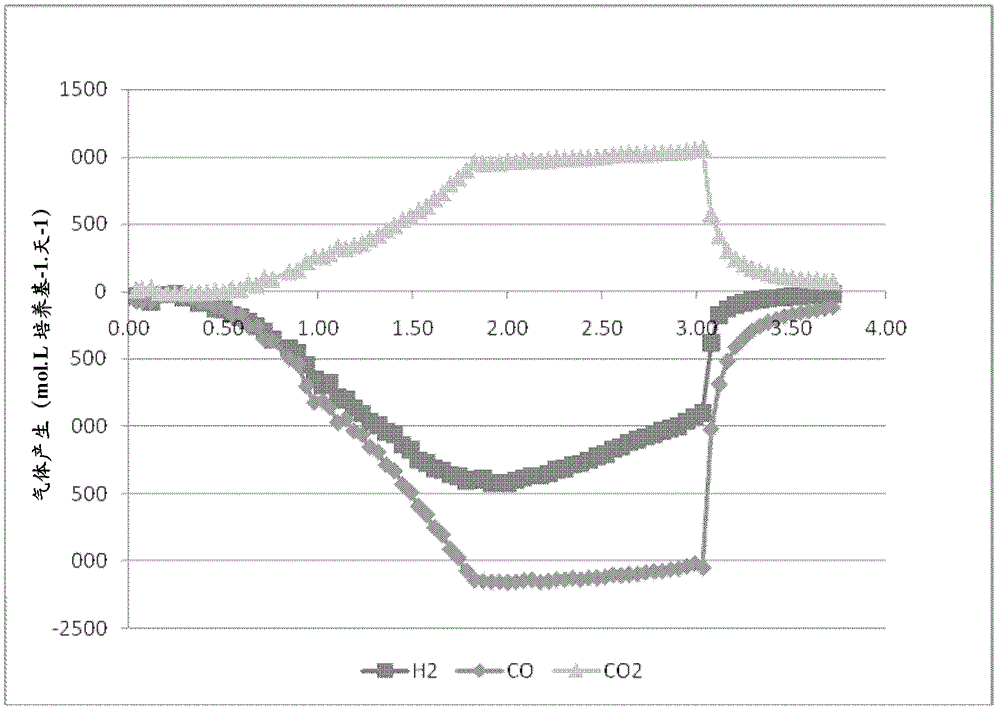

[0171] Example 1: Batch fermentation in CSTR

[0172] Aseptically and anaerobically transfer the liquid culture medium (800 mL) containing solution A into a 1 L CSTR container and continuously wash with N 2 purge. Once transferred, the reduced pressure state and pH of the medium can be measured directly by the probe. The medium was heated to 37°C and stirred at 400 rpm. Phosphoric acid (30 mM), sodium tungstate (10 μM), solution B and solution C were then added. Sodium sulfide solution (0.5 mM) was added to the fermentation vessel, and the medium was then depressurized to 200 mV by adding chromium(II) chloride solution.

[0173] Before inoculation, the N 2 Change to 30% CO, 50% H 2 , 5%CO 2 and 15% CH 4 The gas mixture (Range Fuels syngas) was continuously sparged into the fermentation broth throughout the experiment. A vigorous growing culture of Clostridium autoethanogenum was inoculated onto the CSTR at a volume of approximately 10% (v / v). Depending on the growth o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com