Equipment and method for testing Young modulus and consumption factor of loudspeaker cone

A Young's modulus and loss factor technology, which is applied to the Young's modulus and loss factor testing equipment and testing field of speaker cones, can solve the problem of low accuracy of Young's modulus and loss factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

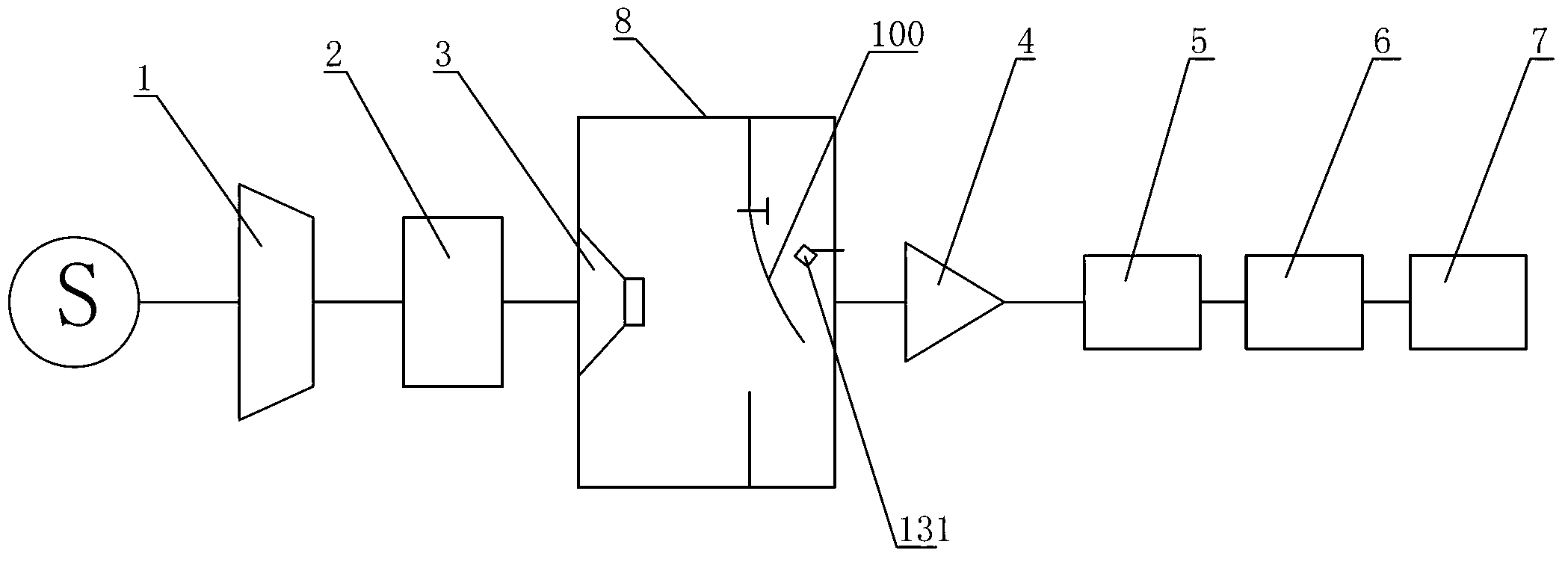

[0088] Speaker cone Young's modulus and loss factor testing equipment includes excitation sound wave generator, vibration device, cone sample fixture, three-dimensional automatic guide rail system, non-contact laser vibration pickup device, processor 6, control cabinet and control panel 7.

[0089] Described excitation sound wave generating device comprises signal generator 1, power amplifier 2 and loudspeaker 3, and signal generator 1 produces sinusoidal signal as excitation source, and the generation of sinusoidal signal and frequency band are controlled by processor 6, and after sinusoidal signal produces, through power amplifier 2 After being amplified, it is input into the speaker 3, and the speaker 3 generates sound pressure.

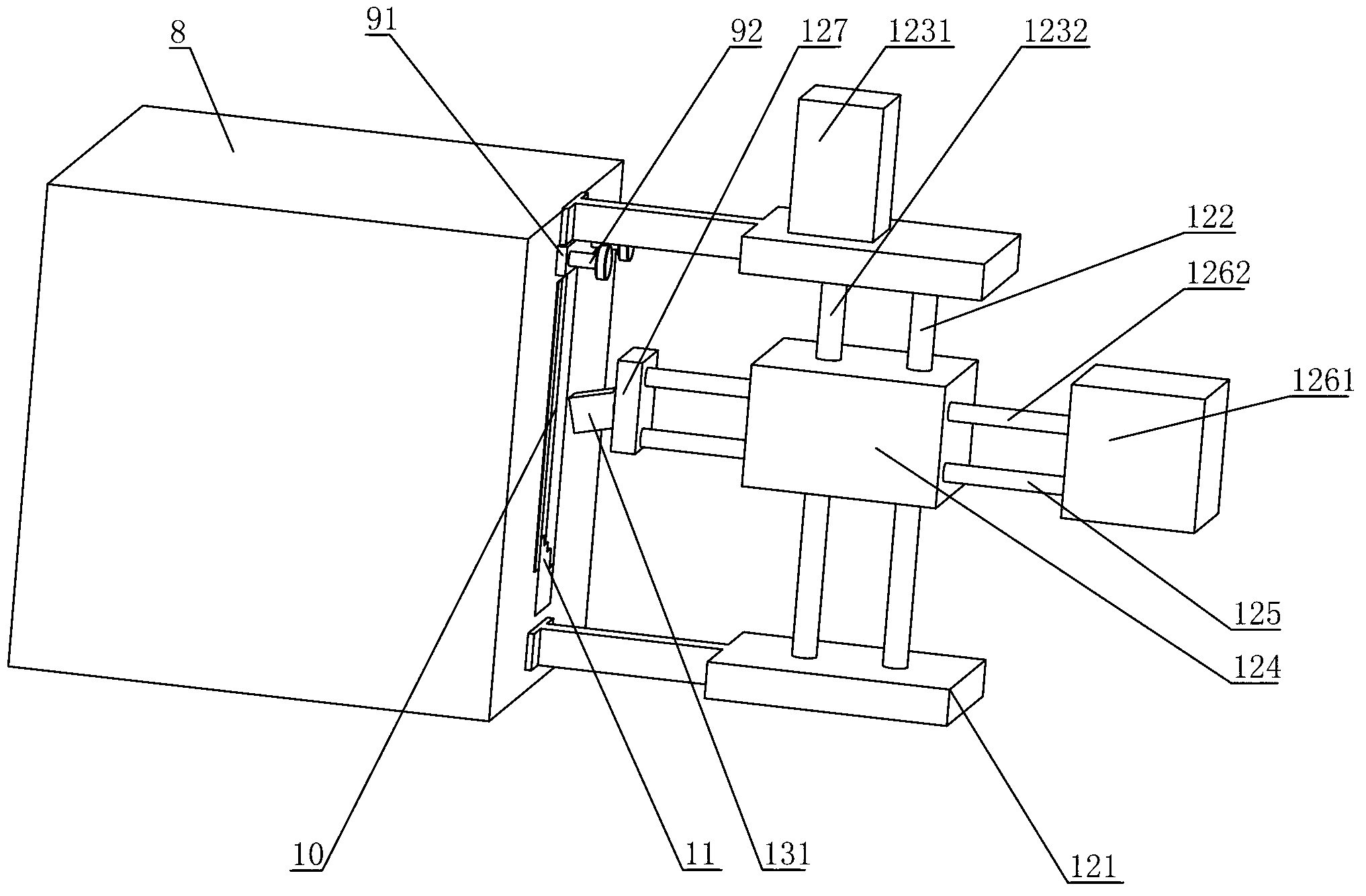

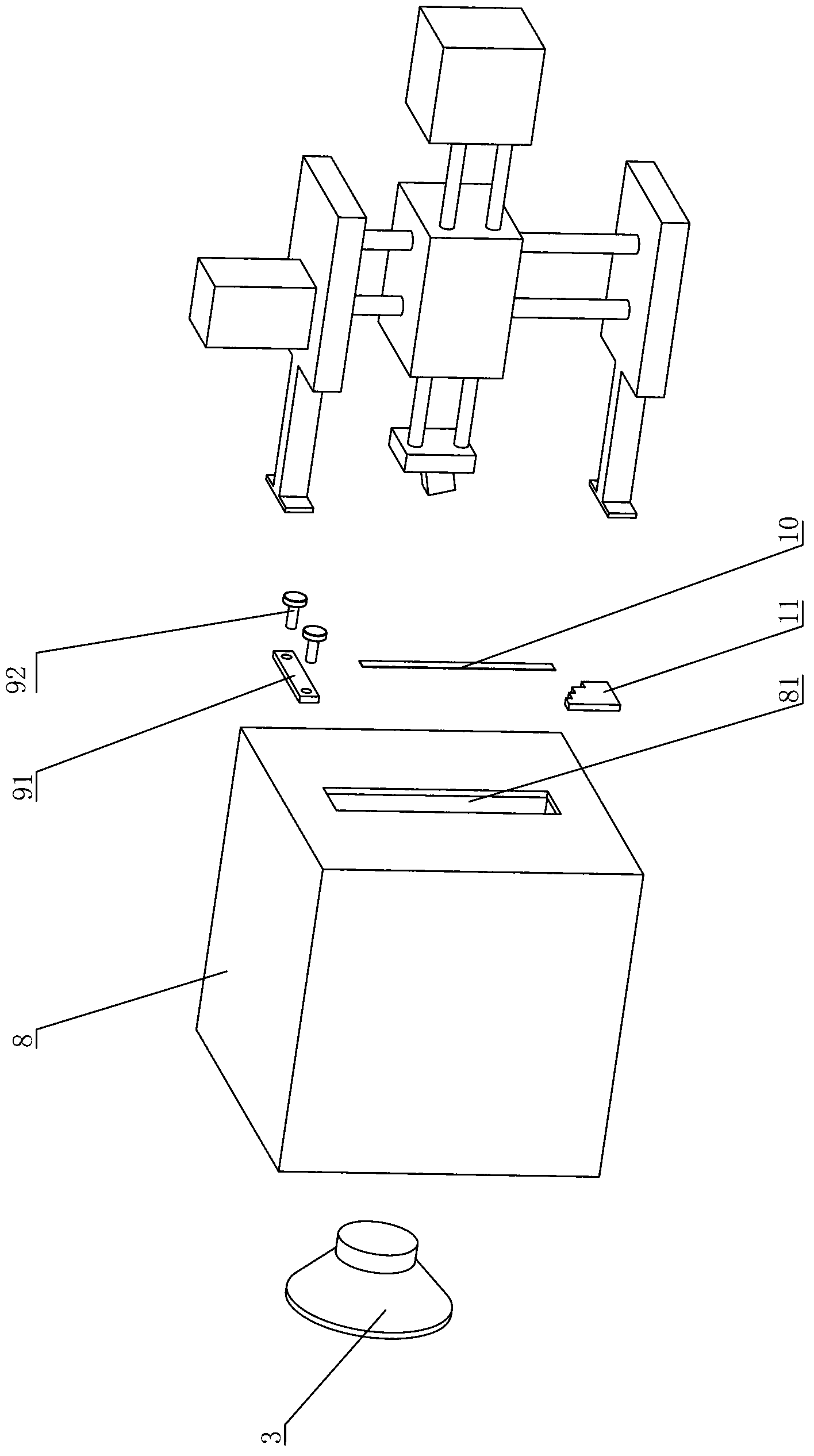

[0090] Such as image 3 and Figure 4 As shown, the excitation device is a box body 8 on which a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com