Dual-voltage power supply circuit and inverter welding machine comprising same

A technology of power circuit and inverter welding machine, which is applied in the direction of circuit devices, emergency power supply arrangements, electrical components, etc., can solve the problems of complex structure of power circuit, burning out power circuit, prone to errors, etc., and achieve the reduction of the size of the welding machine, The effect of reducing failure and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to fully understand the technical content of the present invention, the technical solution of the present invention will be further introduced and illustrated below in conjunction with specific embodiments and accompanying drawings, but is not limited thereto.

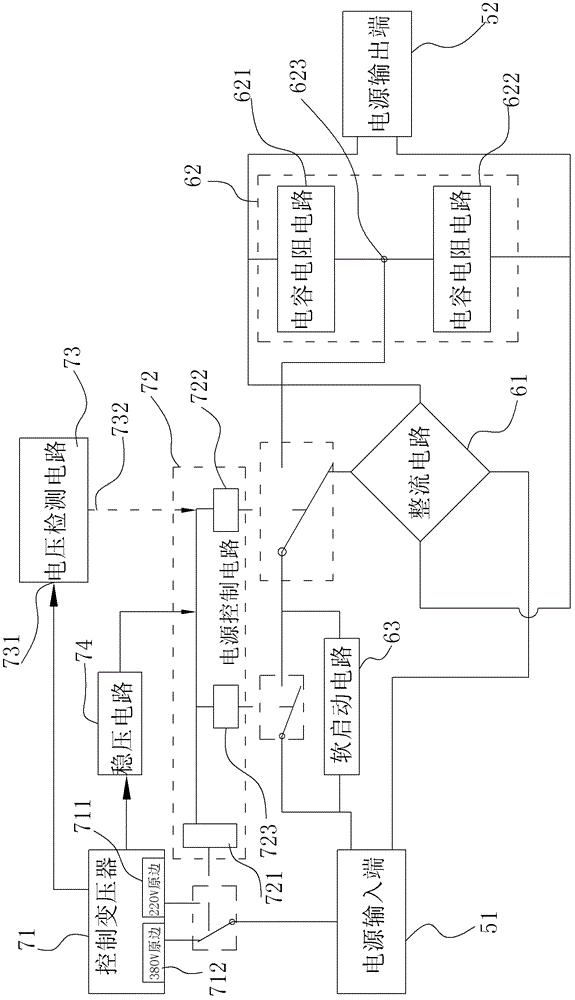

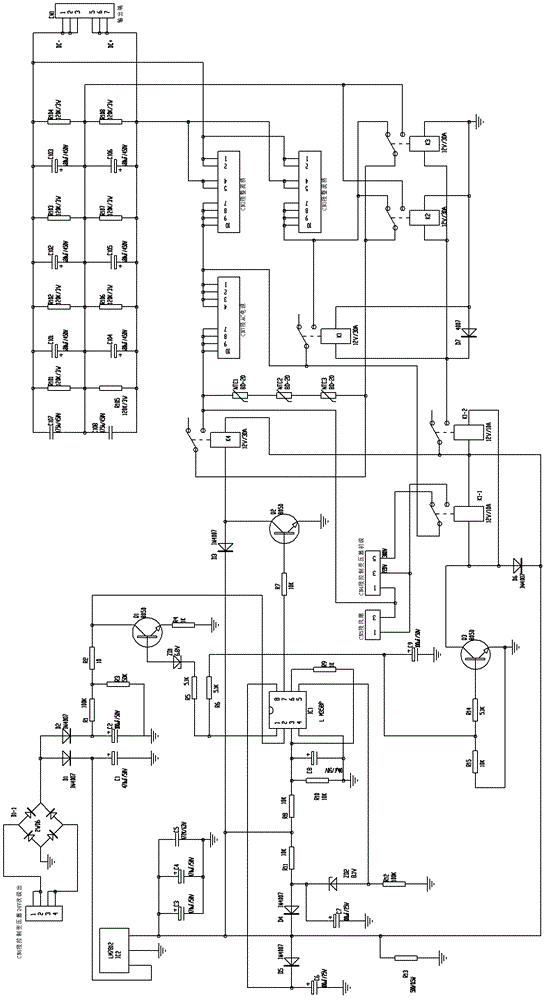

[0041] Such as figure 1 and figure 2 As shown, the dual-voltage power supply circuit of the present invention includes a power supply input terminal 51 and a power supply output terminal 52, a rectifier circuit 61 and a voltage doubler circuit 62 are connected in series between the power supply input terminal 51 and the power supply output terminal 52, and also includes a power supply input terminal 51 connected control transformer 71, and the power control circuit 72 and voltage detection circuit 73 connected with the control transformer 71; the power control circuit 72 includes the first relay 721 located between the power input terminal 51 and the control transformer 71, and located at The second r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com