Meter pointer angle identification method based on image processing

An instrument pointer and image processing technology, which is applied in the field of image processing, can solve the problems of large errors in the frame difference method of instrument pointers, and achieve the effects of eliminating detection deviations, improving performance, and intuitive image processing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

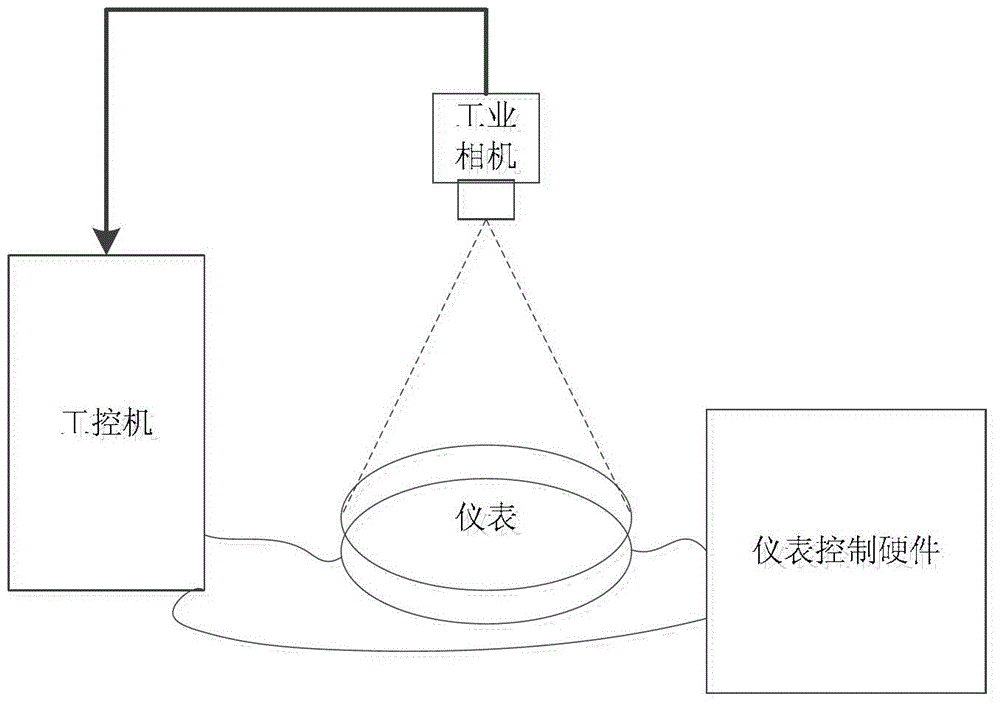

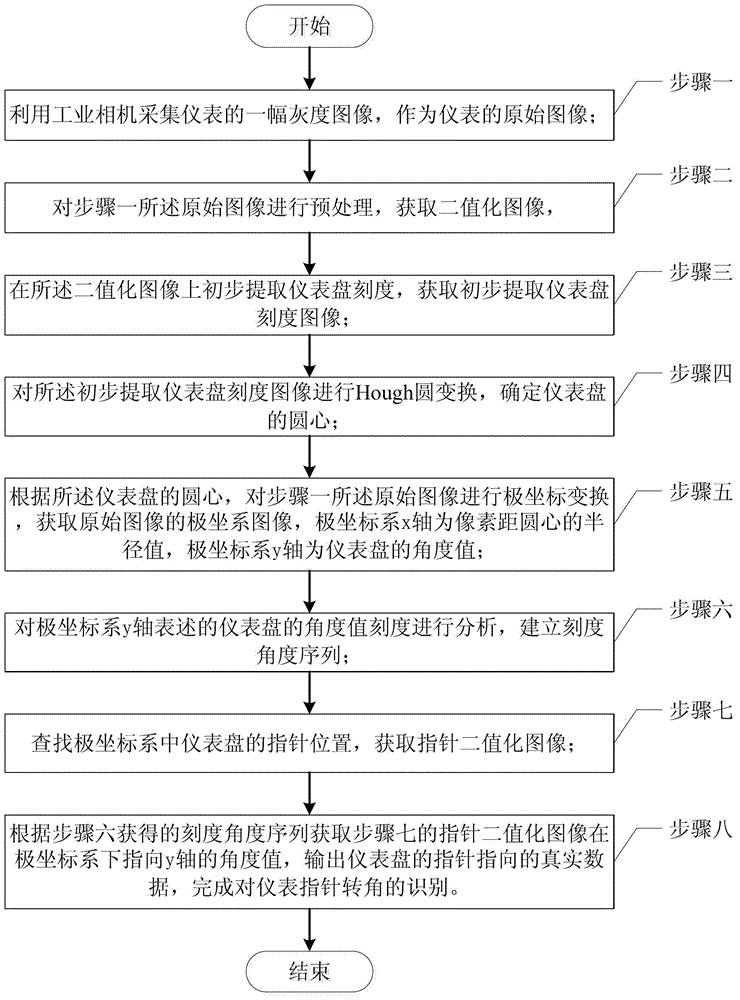

[0046] Specific embodiment one: the following combination Figure 1 to Figure 23 This embodiment will be described. The image processing-based method for recognizing the rotation angle of a meter pointer described in this embodiment includes the following steps:

[0047] Step 1. Use an industrial camera to collect a grayscale image of the instrument as the original image of the instrument; such as Figure 8 shown.

[0048] Step 2: Preprocess the original image described in Step 1 to obtain a binarized image, such as Figure 9 shown.

[0049] Step 3: Preliminarily extract the scale of the instrument panel on the binarized image, and obtain an image of the scale of the instrument panel that is initially extracted; such as Figures 10 to 13 shown.

[0050] Step 4: Perform Hough circle transformation on the initially extracted instrument panel scale image to determine the center of the instrument panel;

[0051] Step 5: Perform polar coordinate transformation on the original ...

specific Embodiment approach 2

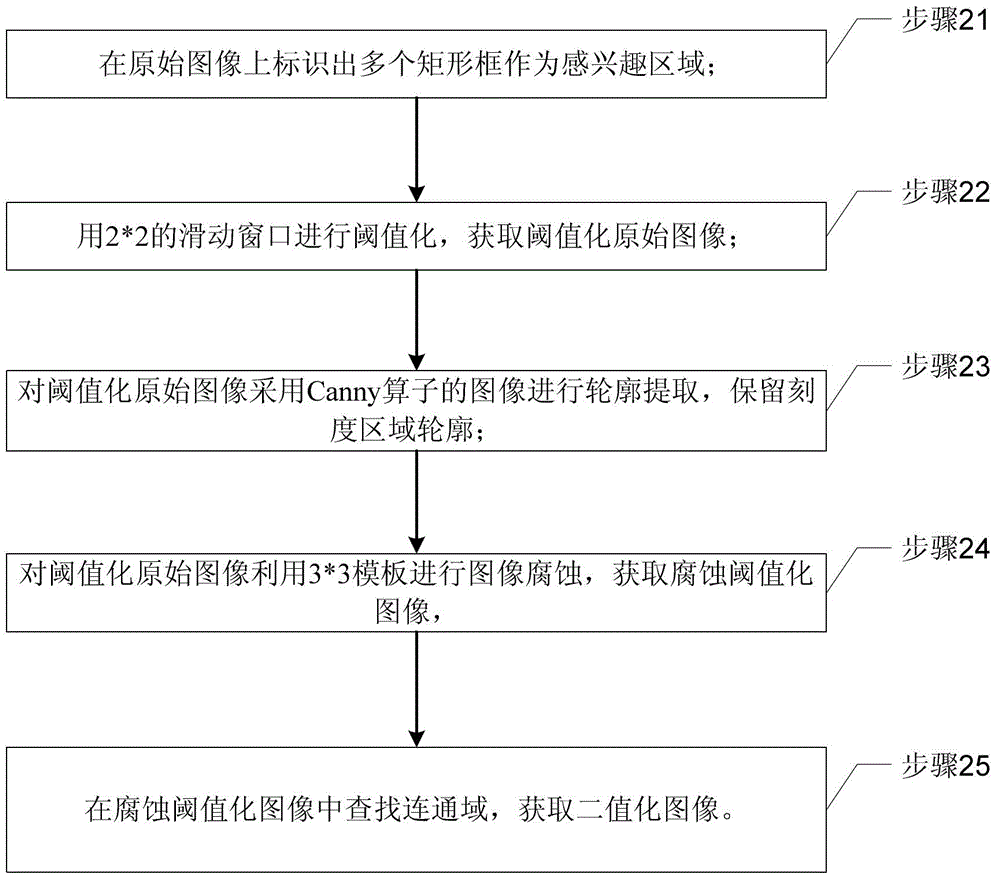

[0057] Embodiment 2: This embodiment further describes Embodiment 1. In step 2, the process of preprocessing to obtain a binarized image is as follows: refer to Figures 10 to 13 .

[0058] Step 21, identifying a plurality of rectangular frames as regions of interest on the original image;

[0059] Step 22: Perform thresholding with a 2*2 sliding window to obtain the thresholded original image;

[0060] Step 23, using the image of the Canny operator to extract the contour of the thresholded original image, and retain the contour of the scale area;

[0061] Step 24: Perform image erosion on the thresholded original image using a 3*3 template to obtain an erosion thresholded image,

[0062] The 3*3 template traverses the thresholded original image, and a pixel is retained when there are pixels in the 3*3 area, otherwise, the pixel is removed;

[0063] Step 25 , searching for a connected domain in the corrosion thresholded image to obtain a binarized image.

[0064] Set featu...

specific Embodiment approach 3

[0065] Embodiment 3: This embodiment further describes Embodiment 1 or 2, and the process of initially determining the center of the instrument panel in step 4 is as follows:

[0066] Step 41. Perform Hough circle transformation on the initially extracted instrument panel scale image, and extract circles that meet the constraints, where the constraints are: the circle contains at least continuous 180° arcs in the image;

[0067] Step 42: Determine whether there is a circle that meets the constraints,

[0068] If the judgment result is yes, then execute step 43; if the judgment result is no, reduce the resolution of the initially extracted instrument panel scale image, and then return to execute step 41;

[0069] Step 43: Using the circle of Hough transform as the benchmark, search the connected domain in the binarized image to obtain an accurate instrument panel scale image, and search for the connected domain in the binarized image to obtain an accurate image that only contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com