Method for establishing load sensitivity controlled axial plunger pump virtual prototype

A technology of load-sensing control and axial piston pump, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of difficult, unrealizable, labor-intensive and time-consuming changes in parameters or conditions, and shorten the design time, reduce experiment cost, and improve experiment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

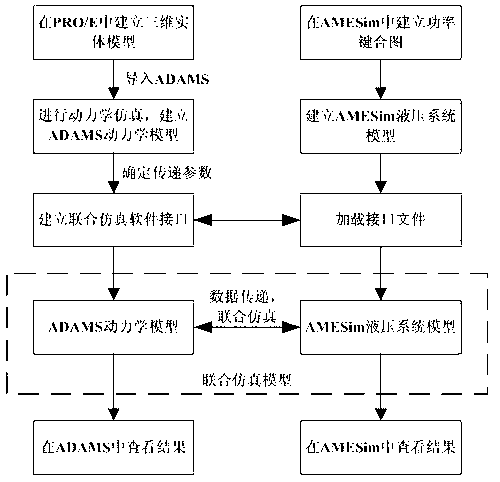

[0019] The method for establishing the virtual prototype of the load sensitive control axial piston pump of the present invention, such as figure 1 shown, including the following steps:

[0020] Step 1: Establish the dynamic model of the axial piston pump in the dynamics simulation software ADAMS, and establish the hydraulic system model of the axial piston pump in the hydraulic system simulation software AMESim;

[0021] Step 2: Use the relevant state variables and parameters related to the dynamic model and the hydraulic system model as the transfer parameters between the two models, use the control module of the ADAMS software to establish a software interface, and then use the tool plug-in (Import ADAMS model) to load the interface file;

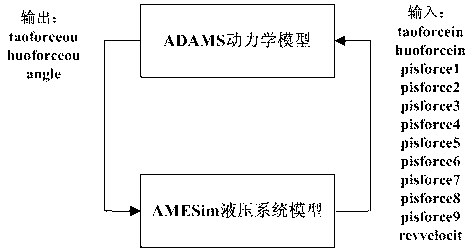

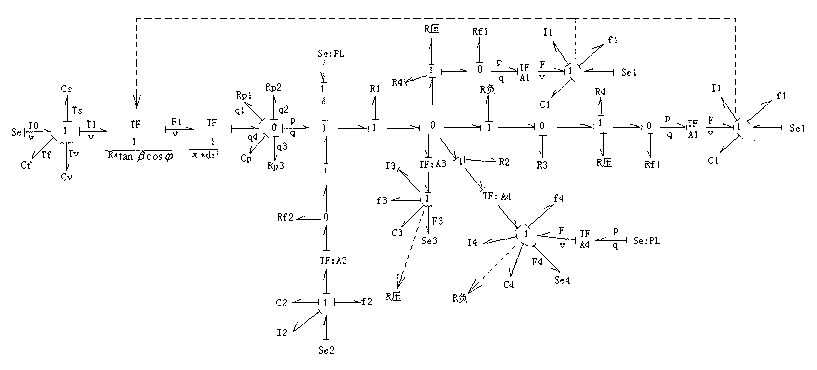

[0022] Step 3: Use the interface module of AMESim and the Control module of ADAMS to conduct joint simulation through the real-time data transfer between the dynamic model and the hydraulic system model: control the pressure (pisforce) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com