Spring optimizing design method

A technology of optimization design and experimental design, applied in calculation, special data processing applications, instruments, etc., can solve the problems of inconvenient optimization design, low precision, and large spring volume in spring design methods, and achieve high accuracy, optimal design, The effect of broad application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

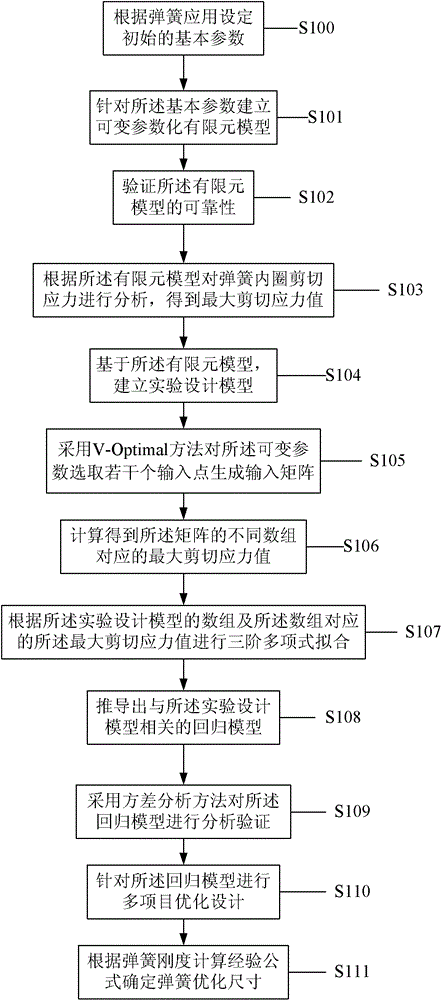

[0028] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0029] Step 100: Set initial basic parameters according to the spring application.

[0030] The basic parameters include the first working length, the second working length, working force and so on. Of course, the basic parameters of the initial design may also include initial load, maximum working load, working stroke and working frequency of the spring, etc.

[0031] Step 101: Establish a variable parameterized finite element model for the basic parameters. Wherein, the variable parameters include the middle diameter of the spring, the diameter of the spring wire and the pitch of the spring.

[0032] In order to achieve the purpose of optimal design, the finite element model needs to have the ability to adjust the several factors most actively affecting the stress in the spring desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com