Brake disc form and location tolerance measuring method and measuring instrument for realizing same

A technology of shape and position tolerance and measurement method, applied in the direction of measurement devices, instruments, etc., can solve the problems of inability to measure the flatness of the upper and lower brake surfaces, the flatness of the plane reference plane, the coaxiality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

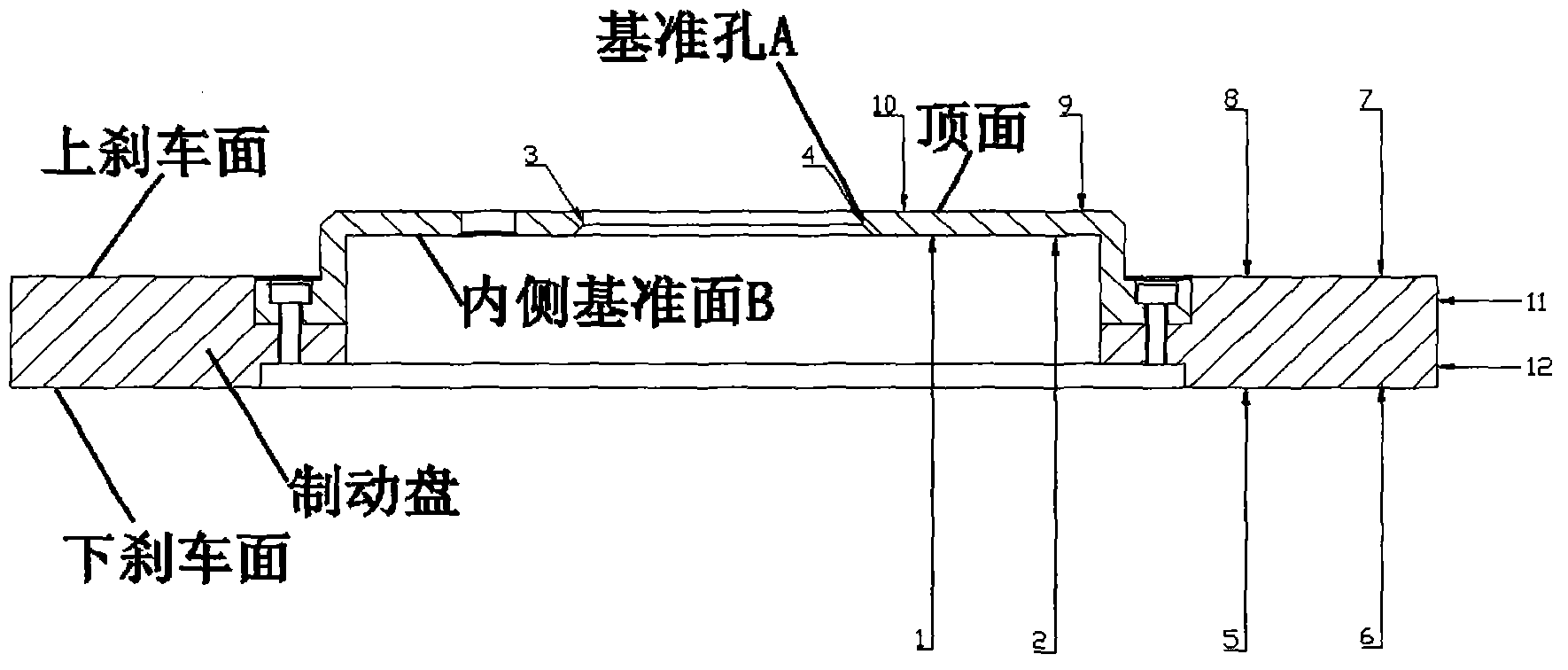

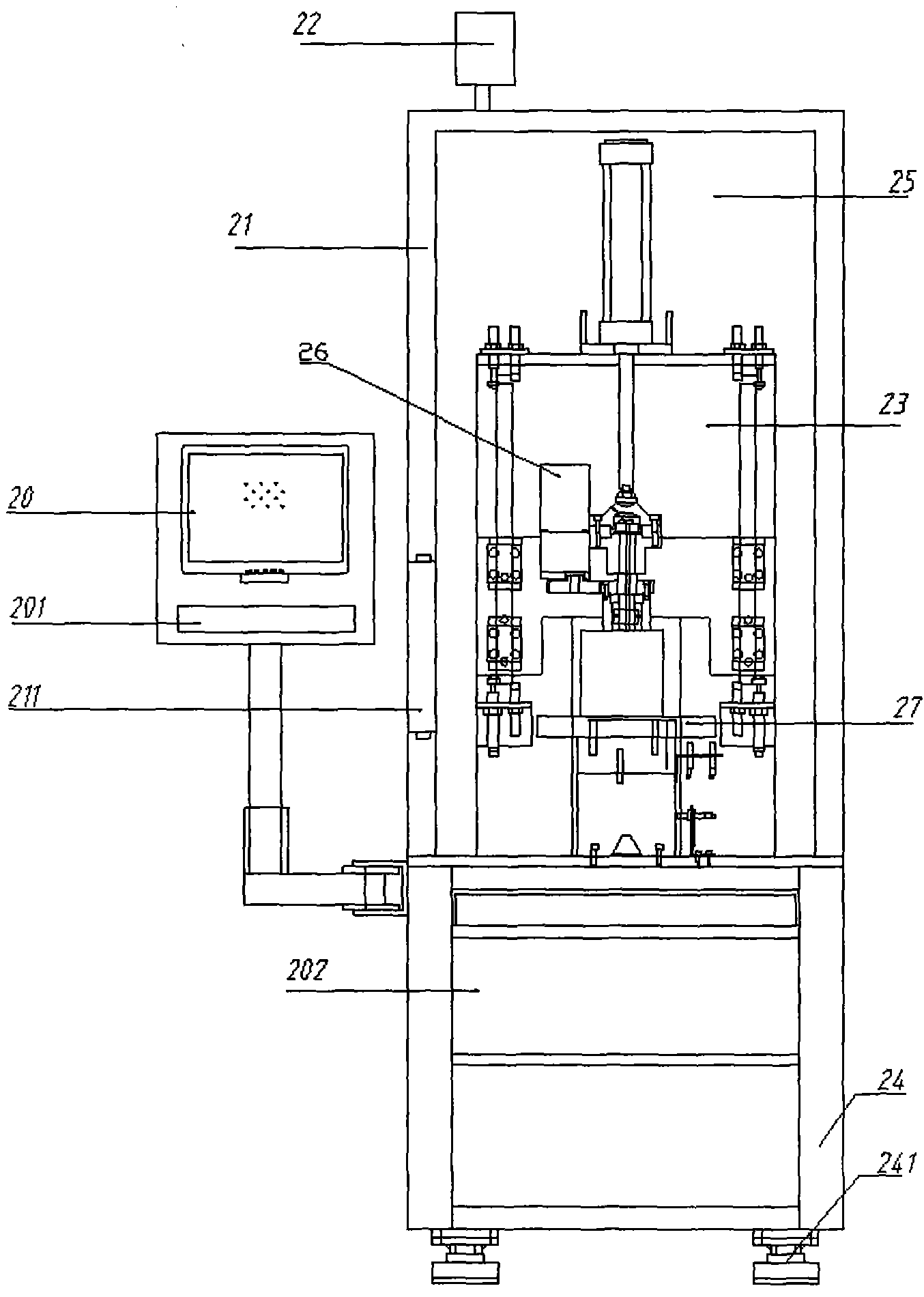

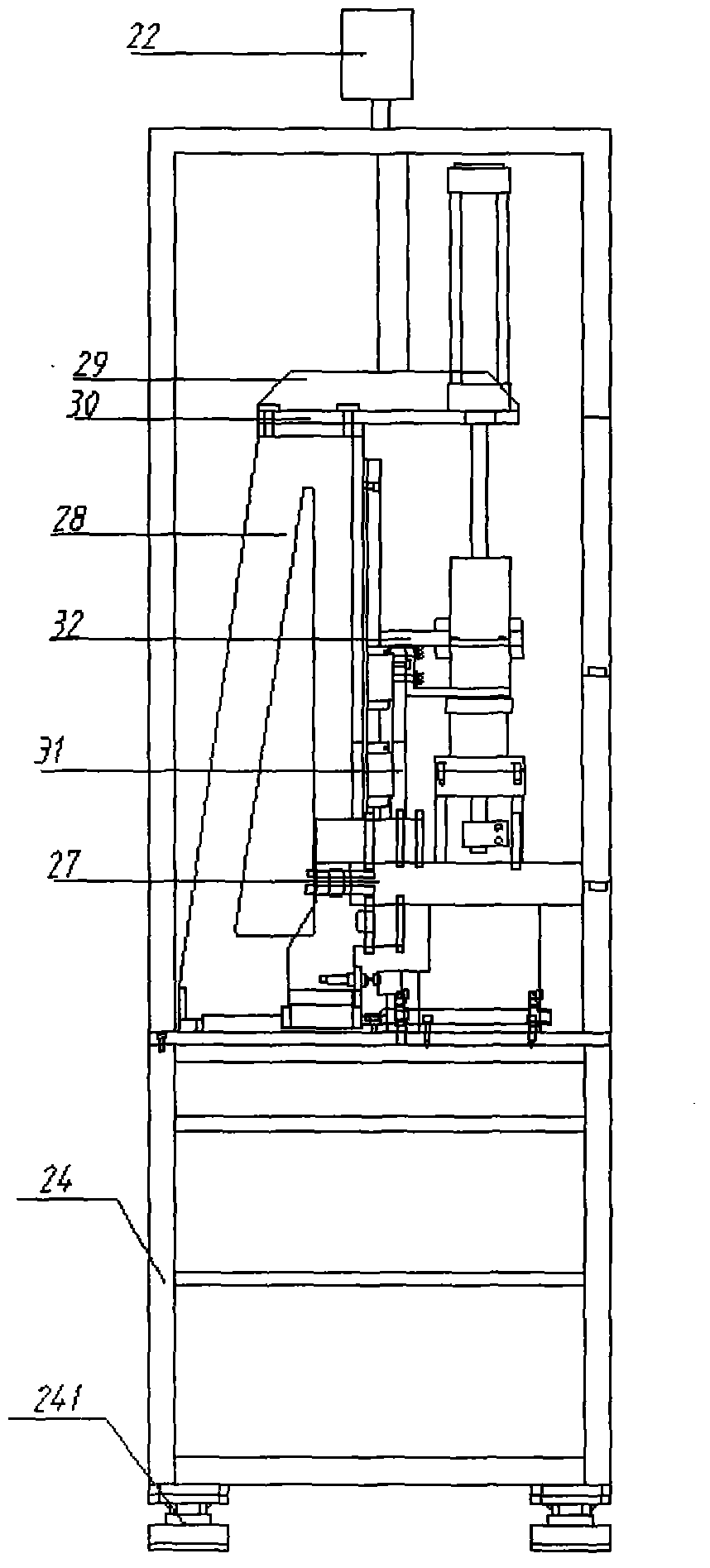

[0032] Such as figure 1 , as shown in 2, a method for measuring the shape and position tolerance of a brake disc and a measuring instrument for realizing the method are used to measure the runout geometric quantity AB of the upper and lower braking surfaces of the automobile brake disc, and the parallelism of the upper and lower braking surfaces of the reference B , the runout geometric quantity AB of the top surface and the parallelism to the reference B, the flatness of the inner plane reference surface B, and the coaxiality of the outer diameter to A.

[0033] A method for measuring a shape tolerance of a brake disc, comprising:

[0034] Set 12 displacement sensors to collect data at 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, and 12 sampling points of the brake disc to collect and measure the runout of the upper and lower braking surfaces and the parallelis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com