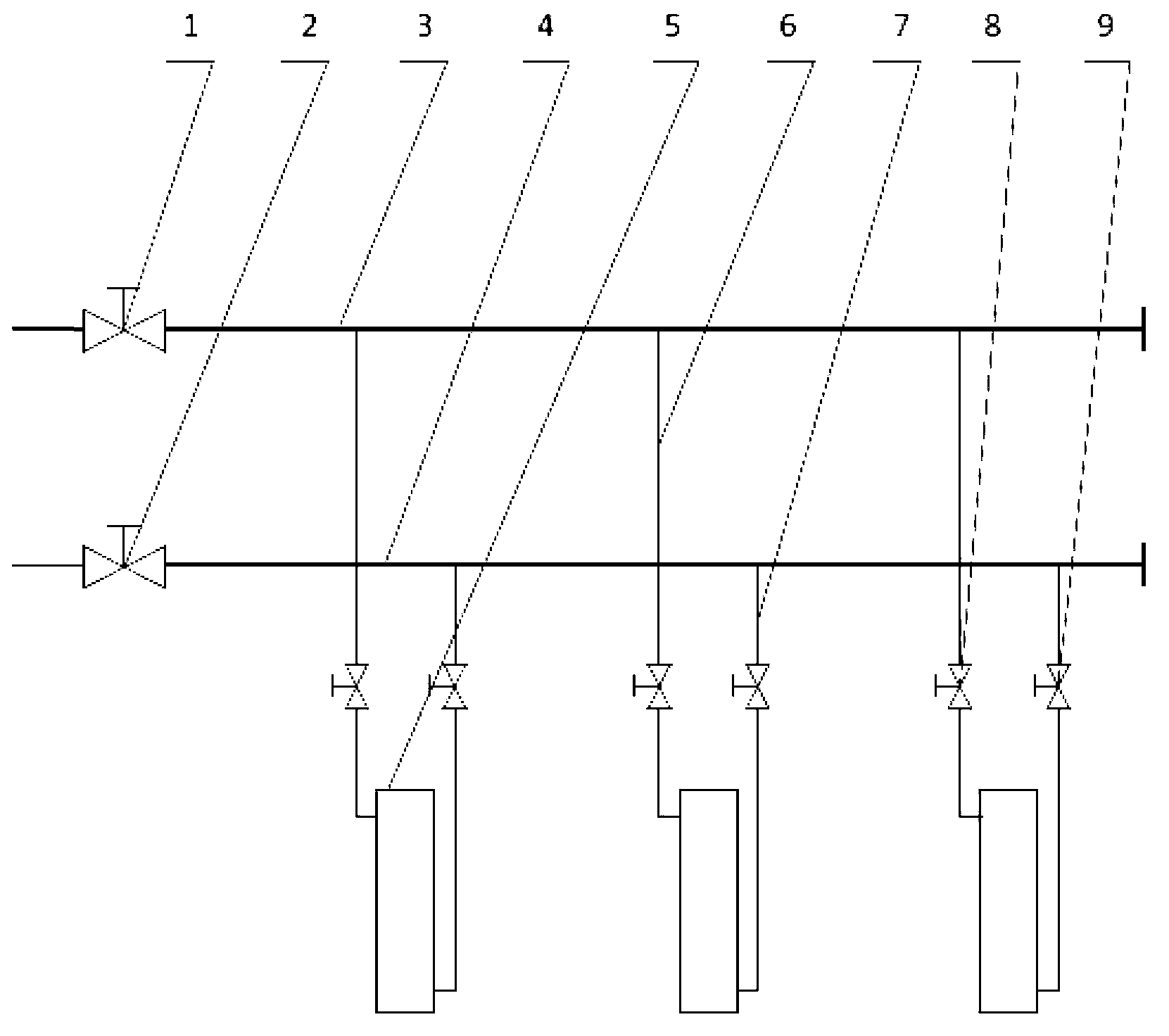

Cooling system capable of on-line cleaning heat exchanger and cleaning method thereof

A cooling system and heat exchanger technology, applied in the direction of cleaning heat transfer devices, flushing, lighting and heating equipment, etc., can solve the problems of labor-intensive, time-consuming equipment downtime, high implementation costs, and avoid offline cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

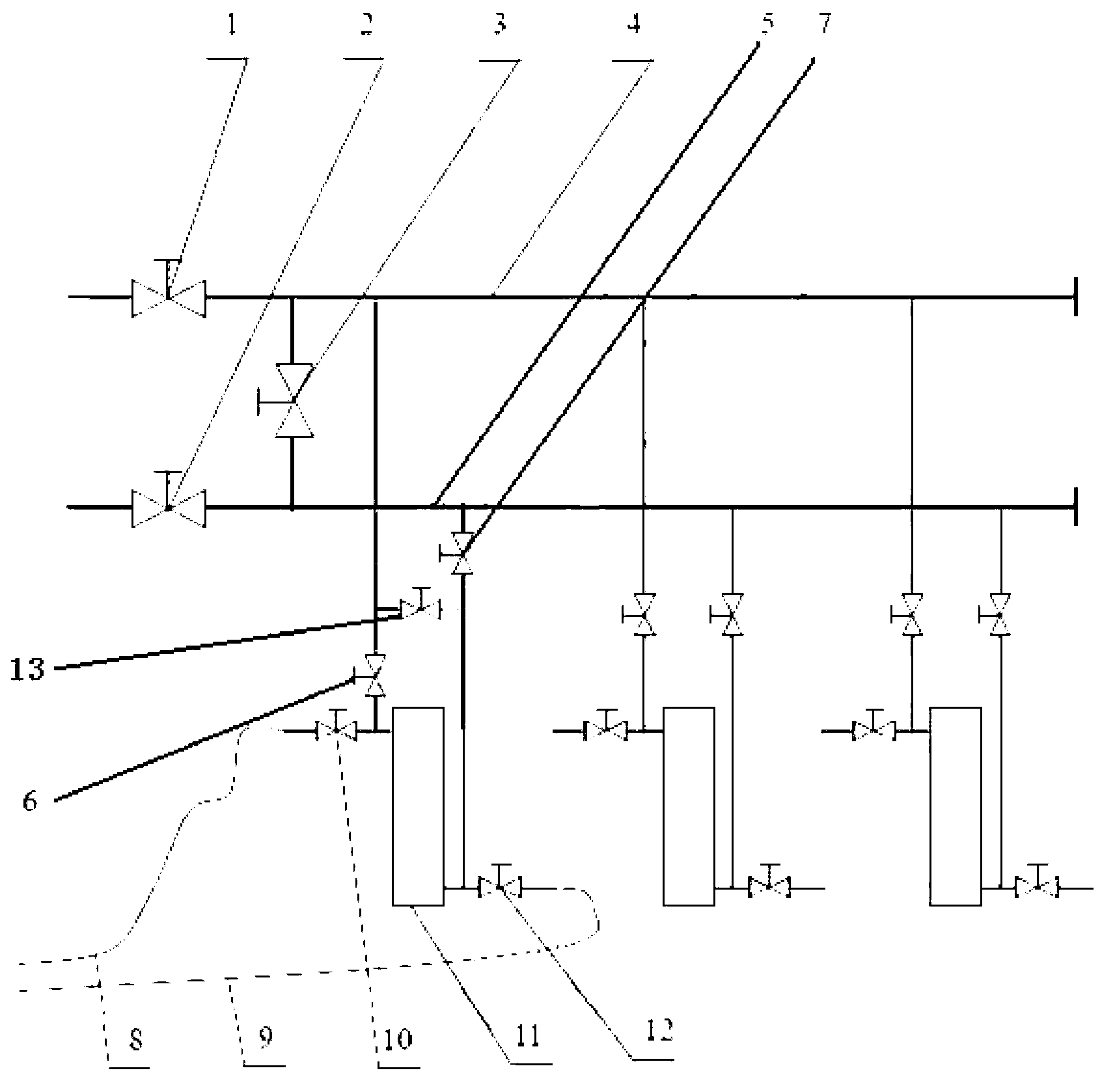

[0013] see figure 2 , a cooling system capable of cleaning heat exchangers online provided by an embodiment of the present invention includes at least two branches, the branches include a heat exchanger 11 and a water inlet and drain valve 10; both ends of the heat exchanger 11 pass through branch pipes They are respectively connected with the main water inlet pipeline 4 and the main water return pipeline 5, and the main water return pipeline is provided with a main water return valve, and meanwhile, the water inlet valve 6 and the water return valve 7 are respectively installed on the branch pipes on both sides of the heat exchanger 11, The water inlet and blowdown valve 10 is installed on the branch pipe between the heat exchanger 11 and the water inlet valve 6 thereof, and the water inlet and blowdown valve 10 is connected with the blowdown pipe 8 .

[0014] Wherein, the cooling system is also equipped with a backwater drain valve 12 on the branch pipe between the heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com