System and method for preventing boom from backward tilting and crane

A technology for anti-back tilting and cranes, applied in the direction of cranes, etc., can solve problems such as boom tipping, casualties, equipment damage, etc., and achieve the effects of avoiding accidents, low cost, and easy manufacturing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following combined with the attachment and the specific embodiments further explained the present invention, but it is not limited to the present invention.

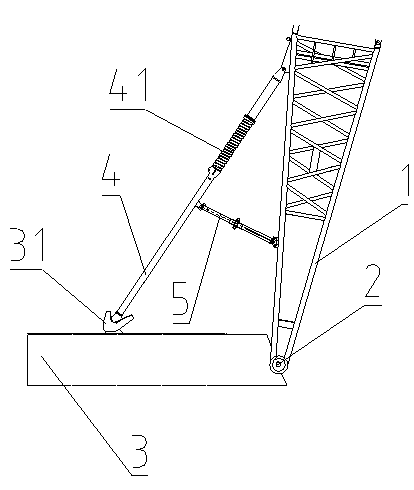

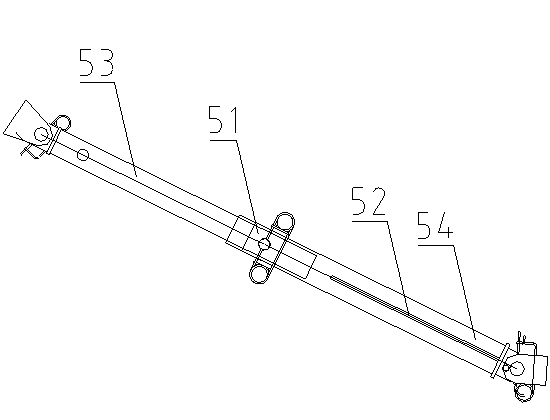

[0023] like figure 1 and figure 2 It is shown in, an embodiment of the system that prevents the back of the arm frame from tilting the back frame.The control device of the connection (not drawn in the figure), the control device and the angle sensing device 2 are connected, and the internal preset of the control device has the maximum rear angle value allowed by the arm frame 1;The anti -rear tilt rod 4 connected to the car platform 3 of the rack and crane crane, the anti -rear tilt rod 4 and the arm frame 1 also hinged with a lever 5, the lever 5 has a telescopic structure 51, the telescopic structure 51 is at the largest trip to the maximum itinerary.The length of the lever 5 is the distance between the tie rod 5 and the arm rack 1 connection to the tie rod 5 and the anti -rear tilt rod 4 connection part at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com